Jepp78bertone

True Classic

Hey folks, So tonight is FIAT friday at my place! Which is not unusual for me as I typically spend my friday nights working on my x, however tonight marks a very special FIAT friday, as tonight is going to be the first attempt at starting my rebuilt engine.

For those of you who have been encouraging me throughout this project, I am so EXCITED to share it with you, regardless of the outcome tonight.

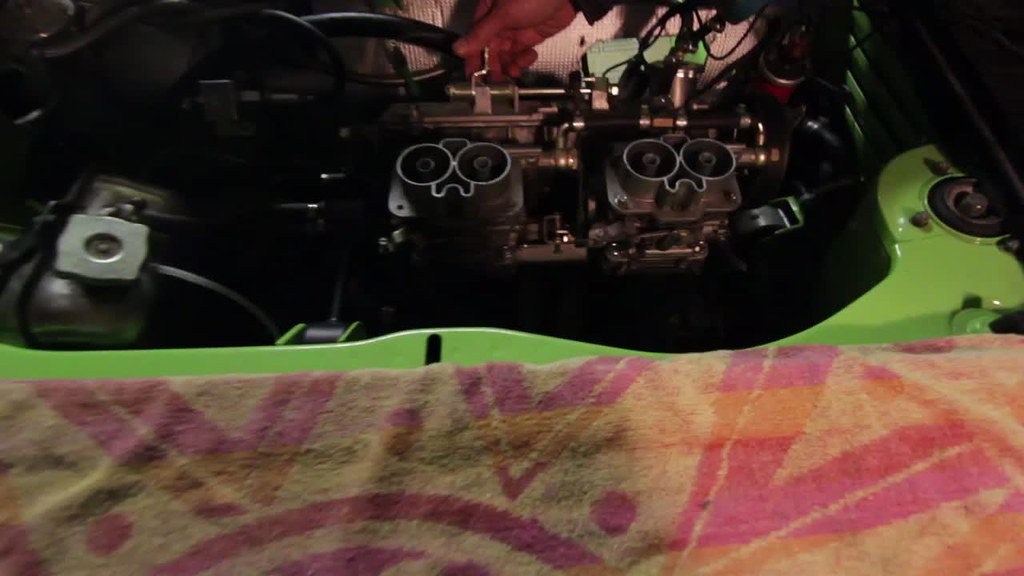

My engine is a 1500 with 86.6mm small fly-cut pistons. Otherwise stock 1500 head that has been ported, polished, and deshrouded following step by step Steve C's fiat performance guide. Twin DCNF 40's on a PBS manifold professionally built by matt. (THANKS ROOSTER) Exhaust is 4-2-1 headers to ANSA free flowing muffler. I am unsure on my camshaft. I bought it off of a gentleman that also sold me the ANSA exhaust set up. It came with a 34DMTR carb that he said was jetted accordingly to the cam and exhaust set up. He said the cam was aftermarket and that together with the set up it gave significantly more performance. I am hoping it works well. If the twin webers seem to cause me a lot of grief, i can switch to my 34DMTR. I had my machinist set the valve clearances when he did a full valve job on the head. I will be running bosch electronic ignition from a 79' x19.

I should remind everybody that is all 100% brand new to me. I have never built an engine before, so if there is anything that needs to be clarified, or something that you see that screams STOP! THIS IS WRONG, please don't hesitate to chime in and save me from seeing 4 years of work blow up in front of me.

I have a question about timing.

Question #1

Do I set my engine to 5'BTDC to start with, or do I leave it at TDC and then once running, with a timing light, set ignition timing to 5'TDC?

As of right now, I have the crank mark in the bell housing opening set to 5'BTDC and the rotor in the disturber pointing to the #4 wire on the cap. wires are set 1-3-4-2. If i open the oil cap, and look down into it - aka #1, both valves are down. Will this be okay, or should I set the crank back to TDC, and then carry out ignition timing with a timing light after it is running?

Question #2. - Vacuum lines

I have no vacuum lines at all. Is that normal for a dual carb set up? I have tried to dig around the forum for info on vacuum advance for dual dcnf's but can't seem to find much.

My distributor has a vacuum port on it, should I plug it? or is it okay to just leave open?

Question #3. - Fuel Pressure

I am running a facet electric solid state fuel pump and a filter king pressure regulator. But I don't have a gauge to know what PSI I am going to be running. I will see if I can get my hands on one before tonight, but if not, is there a way to know if I am pumping too much, or too little fuel?

Thanks everybody, I really appreciate the help! I will make sure that I capture the startup with video, but in the mean time, here are some pictures to enjoy.

SOHC by Josh Epp, on Flickr[url=https://flic.kr/p/yK49ML]

SOHC by Josh Epp, on Flickr[url=https://flic.kr/p/yK49ML] SOHC by Josh Epp, on Flickr

SOHC by Josh Epp, on Flickr Sohc by Josh Epp, on Flickr

Sohc by Josh Epp, on Flickr SOHC by Josh Epp, on Flickr

SOHC by Josh Epp, on Flickr

[/url]SOHC by Josh Epp, on Flickr

[/url]SOHC by Josh Epp, on Flickr

Fingers crossed it will make noise tonight.

-j

For those of you who have been encouraging me throughout this project, I am so EXCITED to share it with you, regardless of the outcome tonight.

My engine is a 1500 with 86.6mm small fly-cut pistons. Otherwise stock 1500 head that has been ported, polished, and deshrouded following step by step Steve C's fiat performance guide. Twin DCNF 40's on a PBS manifold professionally built by matt. (THANKS ROOSTER) Exhaust is 4-2-1 headers to ANSA free flowing muffler. I am unsure on my camshaft. I bought it off of a gentleman that also sold me the ANSA exhaust set up. It came with a 34DMTR carb that he said was jetted accordingly to the cam and exhaust set up. He said the cam was aftermarket and that together with the set up it gave significantly more performance. I am hoping it works well. If the twin webers seem to cause me a lot of grief, i can switch to my 34DMTR. I had my machinist set the valve clearances when he did a full valve job on the head. I will be running bosch electronic ignition from a 79' x19.

I should remind everybody that is all 100% brand new to me. I have never built an engine before, so if there is anything that needs to be clarified, or something that you see that screams STOP! THIS IS WRONG, please don't hesitate to chime in and save me from seeing 4 years of work blow up in front of me.

I have a question about timing.

Question #1

Do I set my engine to 5'BTDC to start with, or do I leave it at TDC and then once running, with a timing light, set ignition timing to 5'TDC?

As of right now, I have the crank mark in the bell housing opening set to 5'BTDC and the rotor in the disturber pointing to the #4 wire on the cap. wires are set 1-3-4-2. If i open the oil cap, and look down into it - aka #1, both valves are down. Will this be okay, or should I set the crank back to TDC, and then carry out ignition timing with a timing light after it is running?

Question #2. - Vacuum lines

I have no vacuum lines at all. Is that normal for a dual carb set up? I have tried to dig around the forum for info on vacuum advance for dual dcnf's but can't seem to find much.

My distributor has a vacuum port on it, should I plug it? or is it okay to just leave open?

Question #3. - Fuel Pressure

I am running a facet electric solid state fuel pump and a filter king pressure regulator. But I don't have a gauge to know what PSI I am going to be running. I will see if I can get my hands on one before tonight, but if not, is there a way to know if I am pumping too much, or too little fuel?

Thanks everybody, I really appreciate the help! I will make sure that I capture the startup with video, but in the mean time, here are some pictures to enjoy.

SOHC by Josh Epp, on Flickr[url=https://flic.kr/p/yK49ML]

SOHC by Josh Epp, on Flickr[url=https://flic.kr/p/yK49ML] SOHC by Josh Epp, on Flickr

SOHC by Josh Epp, on Flickr Sohc by Josh Epp, on Flickr

Sohc by Josh Epp, on Flickr SOHC by Josh Epp, on Flickr

SOHC by Josh Epp, on Flickr

Fingers crossed it will make noise tonight.

-j