lookforjoe

True Classic

Karl clarified the location, I apologize I didn't in my post - I was assuming the stock location was a known given - should have remembered what happens when one assumes too much  .

.

Yes, the AC rebuild thread is here? is they're a link to the AC thread? I tried to print it a year (ish) ago and ran out of ink, then paper, then, then, etc, etc. (short version) it never got done.

Yes, the AC rebuild thread is here

https://xwebforums.com/forum/index....d-upgrade-what-the-wife-wants-she-gets.21920/

and here (for the AC-Heater box rebuild)

http://xwebforums.com/forum/index.php?threads/20043/

And I just spent a lot of time- and with great pain!- restoring all the images on the first one. Still working on the second one. Half-way there.

Nicely done. Thanks.This is what I did

This is what I did (with lots if pictures):

https://xwebforums.com/forum/index....-control-valve-replacement.27435/#post-228926

For me this would definitely have to be placed in the engine compartment; too much heat flowing through the cabin otherwise. And the one drawback I see in mounting the valve in the engine bay is the long actuating cable needed (I'm not real big on vacuum or electronic controls for this application).

Thanks KM.

With the valve being the control for the level of heat offered inside the vehicle (how hot you want to be), I wonder if this bypass style will significantly differ that adjustment. What I mean is how well can the interior temp be controlled, how precise (for lack of better word) is the flow control? We rarely use "full" heat.

But I do see advantages with the constant flow keeping the hoses and valve clean. However it will not help in maintaining the heater core's innards (a problem here due to lack of use). Some vehicles are designed where a small amount of coolant is allowed to constantly pass through the core for that very reason. I wonder if any of these bypass valves do that (intentionally or otherwise)?

For me this would definitely have to be placed in the engine compartment; too much heat flowing through the cabin otherwise. And the one drawback I see in mounting the valve in the engine bay is the long actuating cable needed (I'm not real big on vacuum or electronic controls for this application).

The problem is that most of those plastic valves don't seal all that well. So there is definitely flow even when closed. We discovered this over on one of the American truck sites where we worry about unnecessary heat coming from the heater in the summer- because of one of those plastic valves. They are not that good. The beauty of the original X 1/9 AC valve is it is a clean seal-off of water flow in the summer. In fact, I was thinking of using an X 1/9 heater valve in my Bronco to finally solve that very problem.WoW! There's so much space in there without the AC heater box!

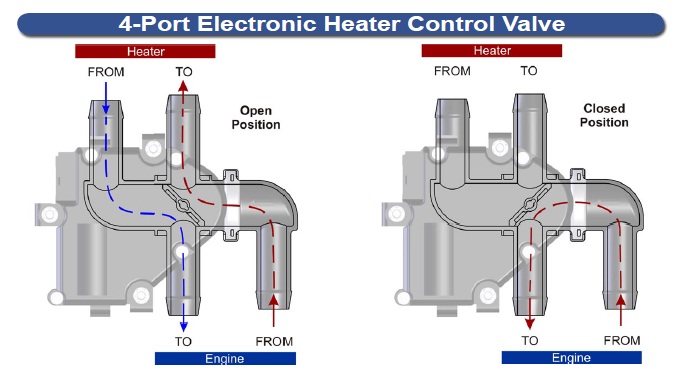

There is no heat transfer with a standard 2 port heater valve when closed, since the heat is only present when there is active flow, or were you referring to a 4 port valve as Karl illustrated?

The problem is that most of those plastic valves don't seal all that well. So there is definitely flow even when closed. We discovered this over on one of the American truck sites where we worry about unnecessary heat coming from the heater in the summer- because of one of those plastic valves. They are not that good. The beauty of the original X 1/9 AC valve is it is a clean seal-off of water flow in the summer. In fact, I was thinking of using an X 1/9 heater valve in my Bronco to finally solve that very problem.

Ya, I was referring to the bypass/4-port valve shown by Karl. Otherwise I agree with you, no significant heat transfer typically. Which is why I will stick with a standard (non-bypass) valve if I don't move it to the engine bay.There is no heat transfer with a standard 2 port heater valve when closed

With the ones I've used (VW source) I haven't found that to be the case. In fact the complete lack of flow throughout the majority of the year causes heater core rot issues.The problem is that most of those plastic valves don't seal all that well.