This guide has good instructions for getting to and taking apart the ignition switch, but the picture links are dead.

xwebforums.com

xwebforums.com

I'm hoping to give some detailed pictures and some notes on what I did to fix my ignition switch. My symptoms were as follows: occasional no crank when turning to start, fluctuating power when I jiggled the key, and in one case loss of power while driving the car. I have an early style car, so there may be differences in the later year models.

First things first, disconnect your battery negative cable. It's obvious but you'll be working with the electrical system. Things can get fried, including yourself, if you don't take this first step.

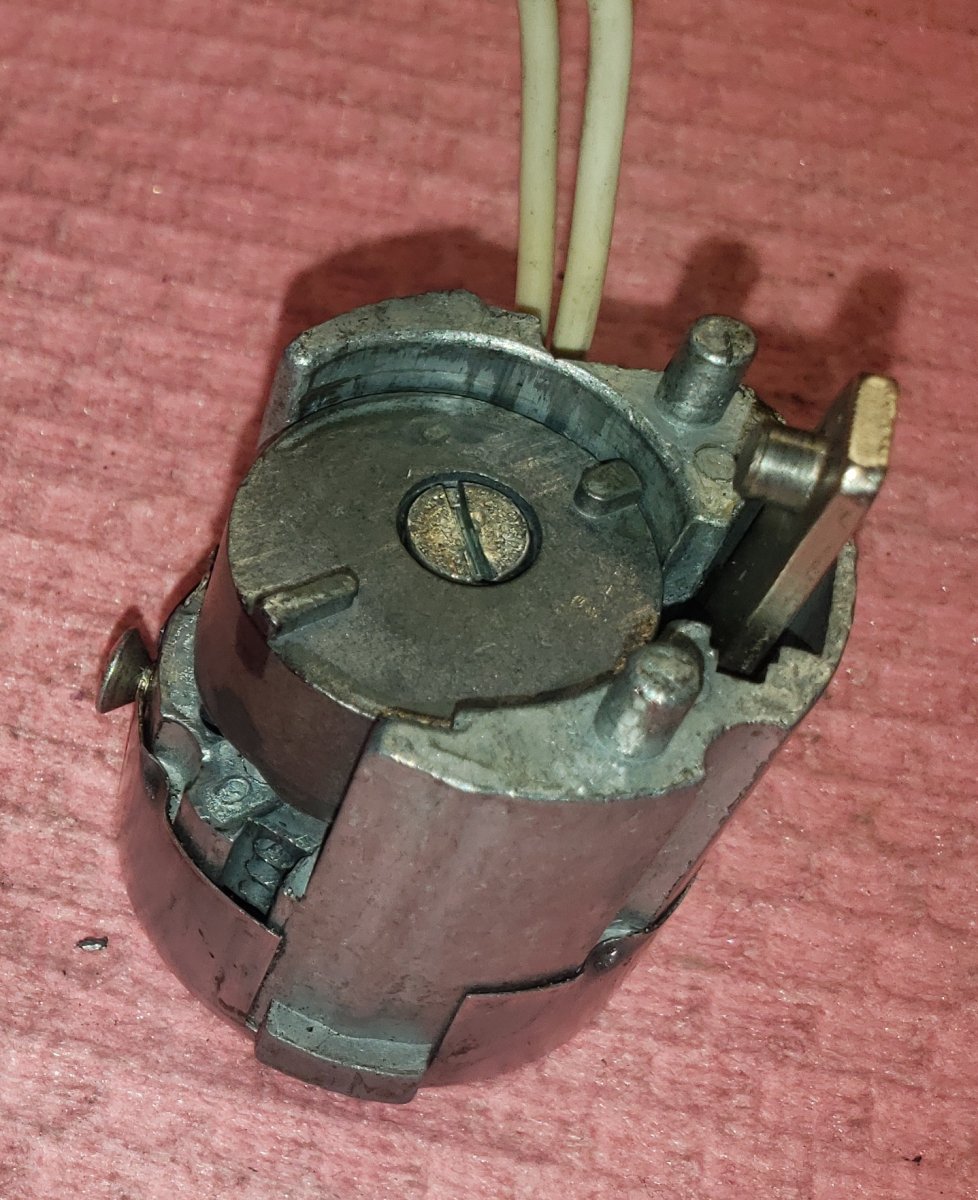

Here is the ignition switch.

There are 5 screws that need to be removed from the bottom of the steering column shroud, one in each of the holes.

To remove the switch you have to take out a small phillips head screw on the back side of it's housing. It is between the dash and the switch. I was able to wedge in a phillips head bit held in my V jaw pliers. The are also great for line nuts. You can more easily get to this screw if you dropped the steering column, which isn't too difficult either.

Next you'll need to remove the wires from the ignition switch pigtail from their housing. Take note of which ones go where.

On some switches there is also a two wire connector for the key in buzzer. It has 2 small white wires going to it.

There is a spring loaded pin in the switch housing that needs to be pressed to remove the switch. It can only be pressed with the key in the ON position. The pin is about 120 degrees counter clockwise from the screw in the back, roughly on the top of the switch when it is in place. I forgot to get a picture of the pin with the switch in place.

With the switch out you can now see the likely culprit of it's failure. On the back of the tumbler there is a plate with two notches. It engages a plate with two channels on the switch mechanism itself. If there ends up enough play in the switch these two plates will not engage each other. And what's worse, if the two black plastic parts of the switch body separate the spring forces actually open the circuits, which could lead to the starter engaging when not in the start position. If the original tube rivets are in good condition hopefully this will not be an issue.

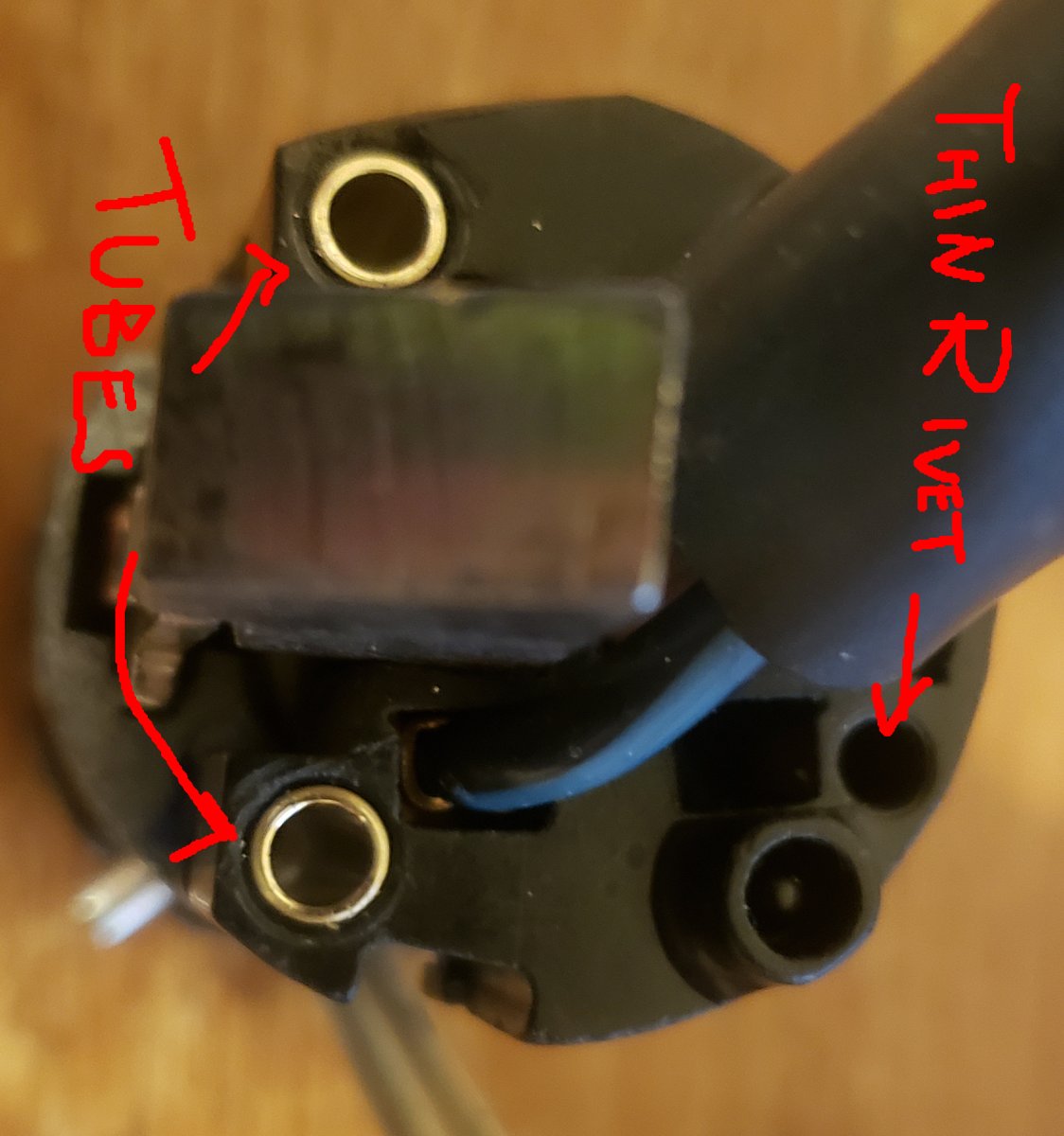

To remove the tube rivets I carefully crimped one side over and pressed it out the other side. I tried drilling them but they just ended up spinning in the switch body. There is also a third very thin rivet that needs to be removed. I had more success drilling out one side of it and then pushing it through the other side.

With the switch out it was time to clean the contacts. Most of mine looked pretty good except for the starting circuit. An eraser works well to clean up the faces. I used some 400 grit paper on the starter pad because it had actually started to erode into it's face. The contacts are crimped on to the wires. Push the wire through to get to the pads and make sure not to lose any of the 3 springs or their rockers. The rocking contacts need to be cleaned as well.

To put the switch back together I decided to cut off the bosses the tube rivets originally sat on and drill and tap for a screw. The metal half of the switch is cast aluminum.

I then made some new tubes that fit the bores in the plastic housing well and are the correct height to keep all the parts of the switch together. This will be the biggest obstacle to a home mechanic. I decided to not worry about the thin rivet on the other side. The switch was very tight put back together like this. I will use a little blue loctite on the threads of my two screws to make sure it doesn't rattle apart.

I forgot to mention the little springs on the back of the switch. I think in the original design they were doing all the work to keep the two plates of the switch together. Who ever came up with that idea should be fired. My plan is to replace them with some longer springs stolen from some clicky pens.

The other part I forgot to mention are the plastic pins underneath the plastic plate of the switch. As the key rotates they are what does the work connecting the different circuits of the switch. When you separate the two halves of the plastic bottom held together by the tube rivets be ready for the plastic pins to fall out. The two halves are springs loaded together because of the rocker contacts that open and close the circuits. If you separate these two parts with the pigtail up the plastic pins will stay in their seats. I recommend not doing it over a metal chip laden floor like I did. There are 3 pins in total.

I plan to reinstall my switch tomorrow. If anyone has any questions or would like some more detailed pictures please let me know.

Ignition Switch - X1/9 Wiki

I'm hoping to give some detailed pictures and some notes on what I did to fix my ignition switch. My symptoms were as follows: occasional no crank when turning to start, fluctuating power when I jiggled the key, and in one case loss of power while driving the car. I have an early style car, so there may be differences in the later year models.

First things first, disconnect your battery negative cable. It's obvious but you'll be working with the electrical system. Things can get fried, including yourself, if you don't take this first step.

Here is the ignition switch.

There are 5 screws that need to be removed from the bottom of the steering column shroud, one in each of the holes.

To remove the switch you have to take out a small phillips head screw on the back side of it's housing. It is between the dash and the switch. I was able to wedge in a phillips head bit held in my V jaw pliers. The are also great for line nuts. You can more easily get to this screw if you dropped the steering column, which isn't too difficult either.

Next you'll need to remove the wires from the ignition switch pigtail from their housing. Take note of which ones go where.

On some switches there is also a two wire connector for the key in buzzer. It has 2 small white wires going to it.

There is a spring loaded pin in the switch housing that needs to be pressed to remove the switch. It can only be pressed with the key in the ON position. The pin is about 120 degrees counter clockwise from the screw in the back, roughly on the top of the switch when it is in place. I forgot to get a picture of the pin with the switch in place.

With the switch out you can now see the likely culprit of it's failure. On the back of the tumbler there is a plate with two notches. It engages a plate with two channels on the switch mechanism itself. If there ends up enough play in the switch these two plates will not engage each other. And what's worse, if the two black plastic parts of the switch body separate the spring forces actually open the circuits, which could lead to the starter engaging when not in the start position. If the original tube rivets are in good condition hopefully this will not be an issue.

To remove the tube rivets I carefully crimped one side over and pressed it out the other side. I tried drilling them but they just ended up spinning in the switch body. There is also a third very thin rivet that needs to be removed. I had more success drilling out one side of it and then pushing it through the other side.

With the switch out it was time to clean the contacts. Most of mine looked pretty good except for the starting circuit. An eraser works well to clean up the faces. I used some 400 grit paper on the starter pad because it had actually started to erode into it's face. The contacts are crimped on to the wires. Push the wire through to get to the pads and make sure not to lose any of the 3 springs or their rockers. The rocking contacts need to be cleaned as well.

To put the switch back together I decided to cut off the bosses the tube rivets originally sat on and drill and tap for a screw. The metal half of the switch is cast aluminum.

I then made some new tubes that fit the bores in the plastic housing well and are the correct height to keep all the parts of the switch together. This will be the biggest obstacle to a home mechanic. I decided to not worry about the thin rivet on the other side. The switch was very tight put back together like this. I will use a little blue loctite on the threads of my two screws to make sure it doesn't rattle apart.

I forgot to mention the little springs on the back of the switch. I think in the original design they were doing all the work to keep the two plates of the switch together. Who ever came up with that idea should be fired. My plan is to replace them with some longer springs stolen from some clicky pens.

The other part I forgot to mention are the plastic pins underneath the plastic plate of the switch. As the key rotates they are what does the work connecting the different circuits of the switch. When you separate the two halves of the plastic bottom held together by the tube rivets be ready for the plastic pins to fall out. The two halves are springs loaded together because of the rocker contacts that open and close the circuits. If you separate these two parts with the pigtail up the plastic pins will stay in their seats. I recommend not doing it over a metal chip laden floor like I did. There are 3 pins in total.

I plan to reinstall my switch tomorrow. If anyone has any questions or would like some more detailed pictures please let me know.

Last edited: