Hi all from a very occasional poster in NZ. Ive just finished converting my lovely but gutless '74 1300 4-spd with a warm 1500 5-spd unit (had to buy the whole car for dismantling, was way too rusty to even consider putting on the road) and might put up a post with pics if I get around to it. Long story short a successful transplant with no metal cut. Anyway. After only around 150 km or so all running sweet, even got the single 40 DCNF properly dyno'ed, a joy to drive etc etc. But its leaking oil around the cam box gasket, its at risk of contaminating the cambelt. I appreciate that this isnt a gasket that compresses, cos of the effect on valve clearances, but still its something that shouldnt happen. All torqued as per Haynes. I was going to try a thin layer of - something - to augment the gasket (eg Hylomar etc), does anyone have any suggestions? Also, I intend to take a walk on the wild side, and re-use the 3-month-old belt if it has no oil contamination evident.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

leaking cam box gasket - and only done 150km!

- Thread starter tonyb

- Start date

Dr.Jeff

True Classic

If it is a gasket that's leaking (not unusual), I like to use a thin coat of Hylomar on pretty much all gaskets to prevent future leaks. It gives a good seal, while most other gasket sealants are too aggressive - they make for a difficult removal and clean up should any additional work be needed down the road. I hate silicone sealants and never use them on engines, but others will disagree.

thanks for the response - thats the first thing I thought of, and did just as you suggested - clean as a whistle under the cam seal, the oily bit only starts below the gasket.A quick question, are you sure it's the gasket and not to the cam shaft oil seal behind the pulley? Maybe worth a clean down and run for a bit to make sure. I wouldn't reuse the belt given it's a relatively small cost vs grief

thanks for the reply, I think i'll do just that. Agree re the silicone - Ive never torn down an engine that has had just enough silicone, its always been way too much.If it is a gasket that's leaking (not unusual), I like to use a thin coat of Hylomar on pretty much all gaskets to prevent future leaks. It gives a good seal, while most other gasket sealants are too aggressive - they make for a difficult removal and clean up should any additional work be needed down the road. I hate silicone sealants and never use them on engines, but others will disagree.

Dan Sarandrea (Phila)

Waitin' On Parts...

I think this has been discussed before and IIRC most people who participated thought that the reason for cam box-to-head leaks was a break in the existing gasket. IOW, when they removed the cambox to replace the existing gasket, they discovered that the existing gasket had split or torn. It's really not surprising since this gasket is extremely thin (due to what you mentioned, that it is made thin on purpose, so it does not compress), it could be damaged easily during installation, or if something gets a little loose, it won't stand up to any sort of movement.

Replacement gaskets are just as thin as originals and aftermarket ones might not be as precisely cut as the OEMs, so IIRC there was a suggestion that the replacement gasket should be soaked in oil for a time in order to swell them up just a bit to aid in installation.

Replacement gaskets are just as thin as originals and aftermarket ones might not be as precisely cut as the OEMs, so IIRC there was a suggestion that the replacement gasket should be soaked in oil for a time in order to swell them up just a bit to aid in installation.

TonyK

True Classic

I soak them in water and it allows the gasket to set on the head for the installation of the cam box. The water flashes off once the engine get's hot and no issues with leaks. When I worked at the Fiat dealership back in the late 70's that is what the mechanics did then.I think this has been discussed before and IIRC most people who participated thought that the reason for cam box-to-head leaks was a break in the existing gasket. IOW, when they removed the cambox to replace the existing gasket, they discovered that the existing gasket had split or torn. It's really not surprising since this gasket is extremely thin (due to what you mentioned, that it is made thin on purpose, so it does not compress), it could be damaged easily during installation, or if something gets a little loose, it won't stand up to any sort of movement.

Replacement gaskets are just as thin as originals and aftermarket ones might not be as precisely cut as the OEMs, so IIRC there was a suggestion that the replacement gasket should be soaked in oil for a time in order to swell them up just a bit to aid in installation.

TonyK.

Grimsby Ontario Canada.

Dan Sarandrea (Phila)

Waitin' On Parts...

I thought I remembered oil but water makes more sense ...I soak them in water and it allows the gasket to set on the head for the installation of the cam box. The water flashes off once the engine get's hot and no issues with leaks. When I worked at the Fiat dealership back in the late 70's that is what the mechanics did then.

TonyK.

Grimsby Ontario Canada.

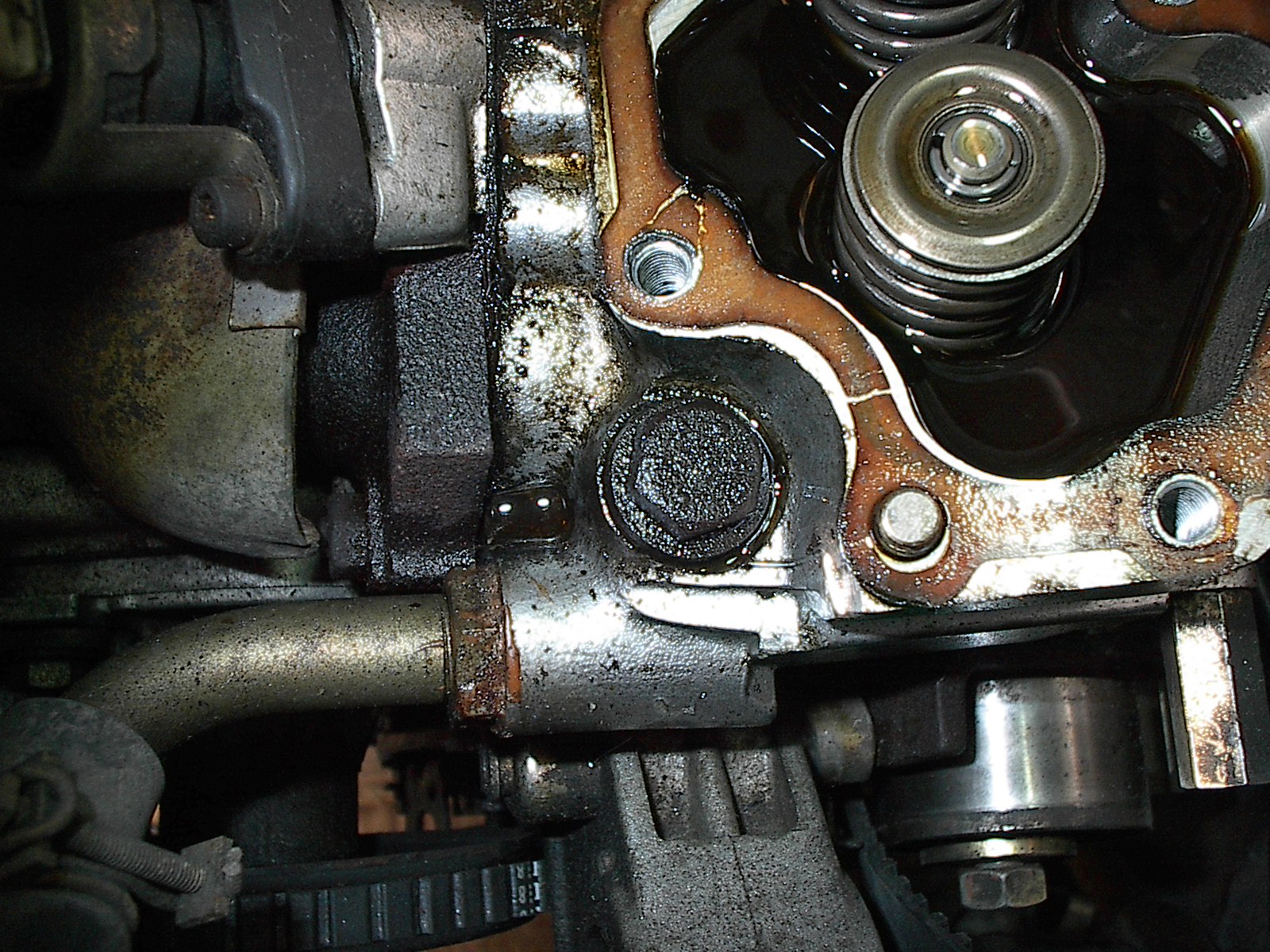

The paper cam box gasket failed on my 86 back in 2010. It leaked near the same area as @tonyb is concerned about. Here is a pic that shows mine had "cracked" on the corner near the cam gear. As recommended by Tony and others at the time, I soaked the paper gasket in warm water. It makes the gasket less brittle and also allows you to "float' it into place. I tried it dry at first and it didn't seem like the gasket was big enough to cover the area required.

Dan Sarandrea (Phila)

Waitin' On Parts...

I think this is one of those situations where the design was a bit ahead of its time and let down by the contemporary materials available and/or reasonable-for-the-day mass production tolerances. In today's engines there are many examples of joints like this being sealed with a "goop" sealer of some type and no gasket.

Ulix

True Classic

On two engines, we have had both the cam box and the top of the head surfaced, then used the highest quality gasket we could find, both sides coated with Hylomar.

They both seeped some oil.

There was a thread here, where one of the resident engineers analysed the sealing flange between the two parts. This thread would be worth looking for. The result was that clamping bolts just aren't placed in the correct spots to insure a good seal.

It seems to be luck whether you get a good seal or not at the bottom of the cambox.

Some people have reported that they bought their X new and had a slight leak there.

Regarding Jeff's comment on removing Hylomar covered gaskets, I have found that disassembling a torqued cambox works great with the Hylomar coated gasket, but as soon as the engine has run and seen some heat, the Hylomar becomes glue.

On an engine that had only run for a couple of days, I had to remove the cambox and the gasket was completely torn to shreds and made a hard to remove mess.

They both seeped some oil.

There was a thread here, where one of the resident engineers analysed the sealing flange between the two parts. This thread would be worth looking for. The result was that clamping bolts just aren't placed in the correct spots to insure a good seal.

It seems to be luck whether you get a good seal or not at the bottom of the cambox.

Some people have reported that they bought their X new and had a slight leak there.

Regarding Jeff's comment on removing Hylomar covered gaskets, I have found that disassembling a torqued cambox works great with the Hylomar coated gasket, but as soon as the engine has run and seen some heat, the Hylomar becomes glue.

On an engine that had only run for a couple of days, I had to remove the cambox and the gasket was completely torn to shreds and made a hard to remove mess.

myronx19

True Classic

There was a thread here, where one of the resident engineers analysed the sealing flange between the two parts.

Yep! That would be @Paul Valente who did a nice write up about that. He knows what he's talking about!

Cambox gasket thumbnail analysis

My spirits were buoyed after my recent post on liquid gaskets and some of the excellent discussion by other XWEB members. People generally seemed to like this insight, were respectful, no one hijacked it or told me I was all messed up. So, pressing my luck, I thought I would take a closer look...

xwebforums.com

Dr.Jeff

True Classic

I agree with you, Myron, and Paul about the design not allowing proper clamping. I feel this is also true in other areas of the engine and trans (and elsewhere on the car).On two engines, we have had both the cam box and the top of the head surfaced, then used the highest quality gasket we could find, both sides coated with Hylomar.

They both seeped some oil.

There was a thread here, where one of the resident engineers analysed the sealing flange between the two parts. This thread would be worth looking for. The result was that clamping bolts just aren't placed in the correct spots to insure a good seal.

It seems to be luck whether you get a good seal or not at the bottom of the cambox.

Some people have reported that they bought their X new and had a slight leak there.

Regarding Jeff's comment on removing Hylomar covered gaskets, I have found that disassembling a torqued cambox works great with the Hylomar coated gasket, but as soon as the engine has run and seen some heat, the Hylomar becomes glue.

On an engine that had only run for a couple of days, I had to remove the cambox and the gasket was completely torn to shreds and made a hard to remove mess.

Regarding Hylomar, I haven't experienced it turning to glue with time like that. Maybe a difference in thermal levels? I run my engines with a 160* F thermostat, oversized rad/fans, oil cooler, etc. So they never reach the temp levels that I see many people here report for their X's. Not sure if that's enough to make a difference? Or maybe I've been lucky.

I have disassembled engines and trans where I see a previous owner had used Hylomar. I noticed pronounced irregularities in the aluminum casting of the gasket mating surface. Those appeared rougher than most and the Hylomar that was deep in the irregularities was more difficult to clean off. But that was a function of the surface finish. And it did not leak. But I've not had it destroy gaskets.

Just for the sake of discussion. There's been mention of soaking the thin paper gaskets before installing. And pics of the "splits" that have formed in the gasket, allowing leaks. I wonder the soaking, and resultant swelling, later shrinks back due to heat cycles. And that shrinkage is what causes the cracks (and leaks). Personally I do not soak mine, but a use a dressing as I discussed above.

speedy fiat

True Classic

Its was standard to use 'Wellseal Jointing Compound' on early Lotus 907 engine cam covers due to the crappy design. It would certainly be worth considering to the Fiat SOHC engine

Dr.Jeff

True Classic

I haven't tried that particular sealant so I don't know how it compares. But I have used most of the ones in the kit linked below:Its was standard to use 'Wellseal Jointing Compound' on early Lotus 907 engine cam covers due to the crappy design. It would certainly be worth considering to the Fiat SOHC engine

Porsche Supertec Performance Case Sealant Kit SPTC SUP CSK 001 SPTCSUPCSK001 SPTC.SUP.CSK.001 | Pelican Parts

Supertec Performance Case Sealant Kit $129.00. Call (310)626-8765. May Qualify For FREE SHIPPING. Parts# SPTC SUP CSK 001 SPTC.SUP.CSK.001 SPTCSUPCSK001. Taycan, Spyder, Panamera, Macan, Cayman, Cayenne, Boxster, 968, 944, 930, 928, 924, 914, 912, 911, 718, 356SC, 356C, 356B, 356A.

www.pelicanparts.com

The ones that really seal well are also the ones that are almost impossible to separate and remove later. They are glues more than dressings. And some are "permanent". If you don't expect to be removing the cam box again then they will offer a great seal.

How is "Wellseal" in this respect?

myronx19

True Classic

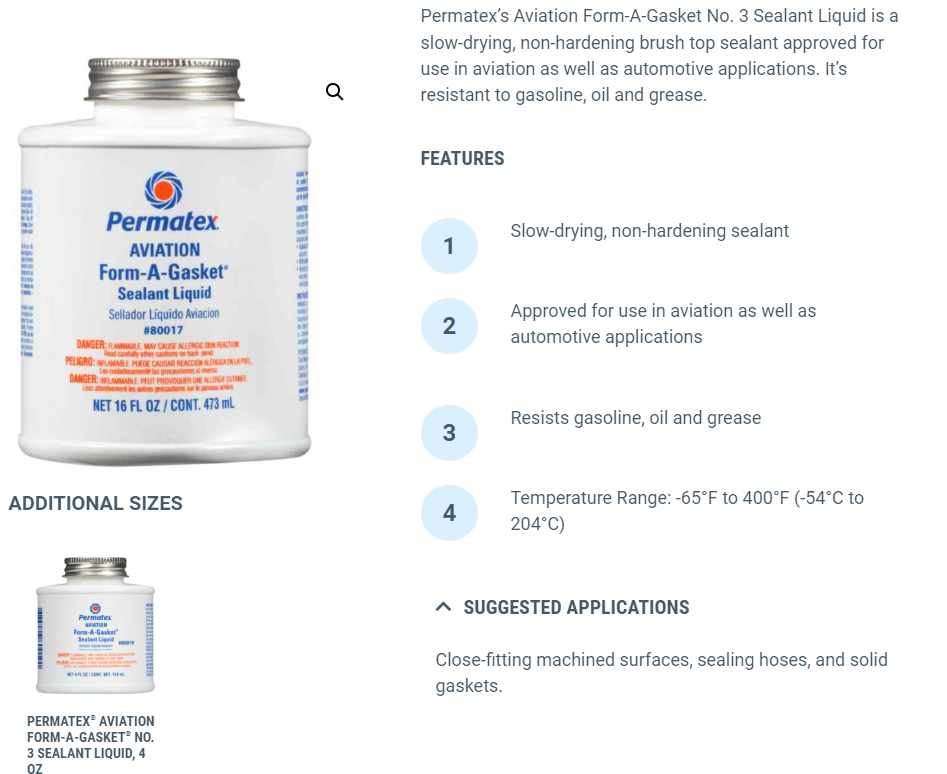

I really like the Permatex Aviation Form-A-Gasket to dress gaskets. It's non-drying. I've recently used it on an old Mopar timing cover and water pump gasket, including the bolts that are in wet bosses.

Also, Permatex "The Right Stuff" is a fantastic rubber sealant that replaces gaskets. It is not silicone - not cheap, but it's great.

Also, Permatex "The Right Stuff" is a fantastic rubber sealant that replaces gaskets. It is not silicone - not cheap, but it's great.

Dr.Jeff

True Classic

Ulix, it occured to me that there's several "Hylomar" products. Perhaps you use a different one than me? And they might make different formulas for different parts of the world. I know that is true for other similar products, due to various chemical regulation differences.I have found that disassembling a torqued cambox works great with the Hylomar coated gasket, but as soon as the engine has run and seen some heat, the Hylomar becomes glue.

Myron, although it is "non-hardening" do you find that it is difficult to separate the components and clean it off later on? That's been my experience.I really like the Permatex Aviation Form-A-Gasket to dress gaskets. It's non-drying.

myronx19

True Classic

difficult to separate the components and clean it off later on?

I intend to never separate the components again

jimmyx

True Classic

Form-A-Gasket has been around since the beginning of time. It's one of those sealers in the shellac family like Indian Head and Copper Coat. It dries very slowly, but when it hardens it entails lots of scraping to get all the gasket material off but the residue that's left is easily removed with acetone. Still a mess nonetheless. Most shops use it for coating the bore on core/freeze plugs prior to installation.do you find that it is difficult to separate the components and clean it off later on?