Rupunzell

Bernice Loui

Almost a month since the deliver of the MS850. Much time has been piled into check out, set up and more to get the MS850 normalized into the shop. The MS850 has been and running day one of delivery.. Except it takes a LOT more time to level, set up and get tooling to work as needed.

Leveling third try.. there will be more as the lathe and all settles:

Lighting added, DRO display mounting made, tooling some what sorted out, chucks and 5c collet set up made to go, set up the MultiFix B tool post and ...

This is what the MS850 looks like in recent times.

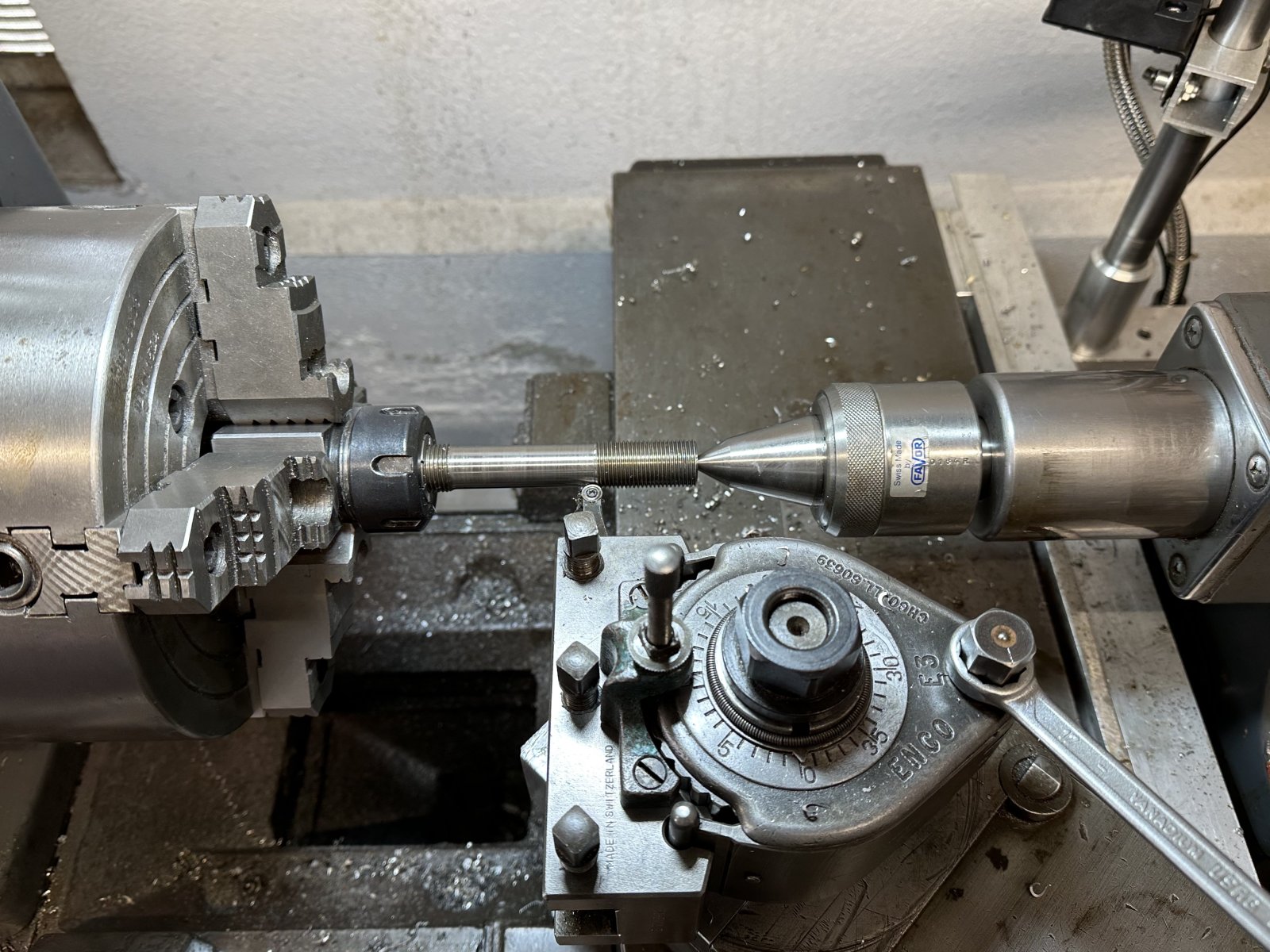

Making a 3/4-16 tpi, B7 chrome-moly steel stud from threaded rod for the Multifix tool post. Un-needed threads are removed with radius ends where the threads meet the center unthreaded area. This is good design to remove what are essentially stress risers (external threads) where not needed. Set up like this:

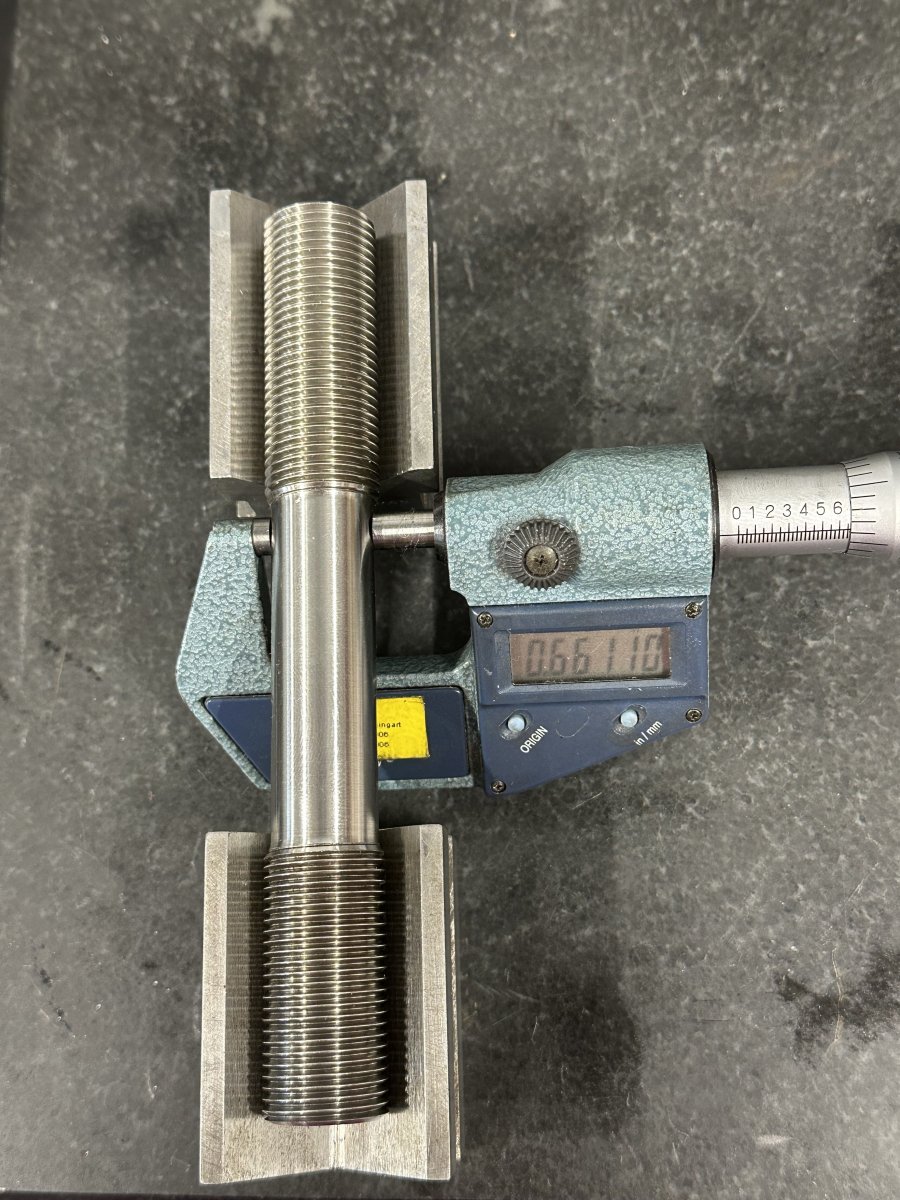

The turned down section is about 3", diameter variation measures 0.0002" direct off the MS850.

Bottom

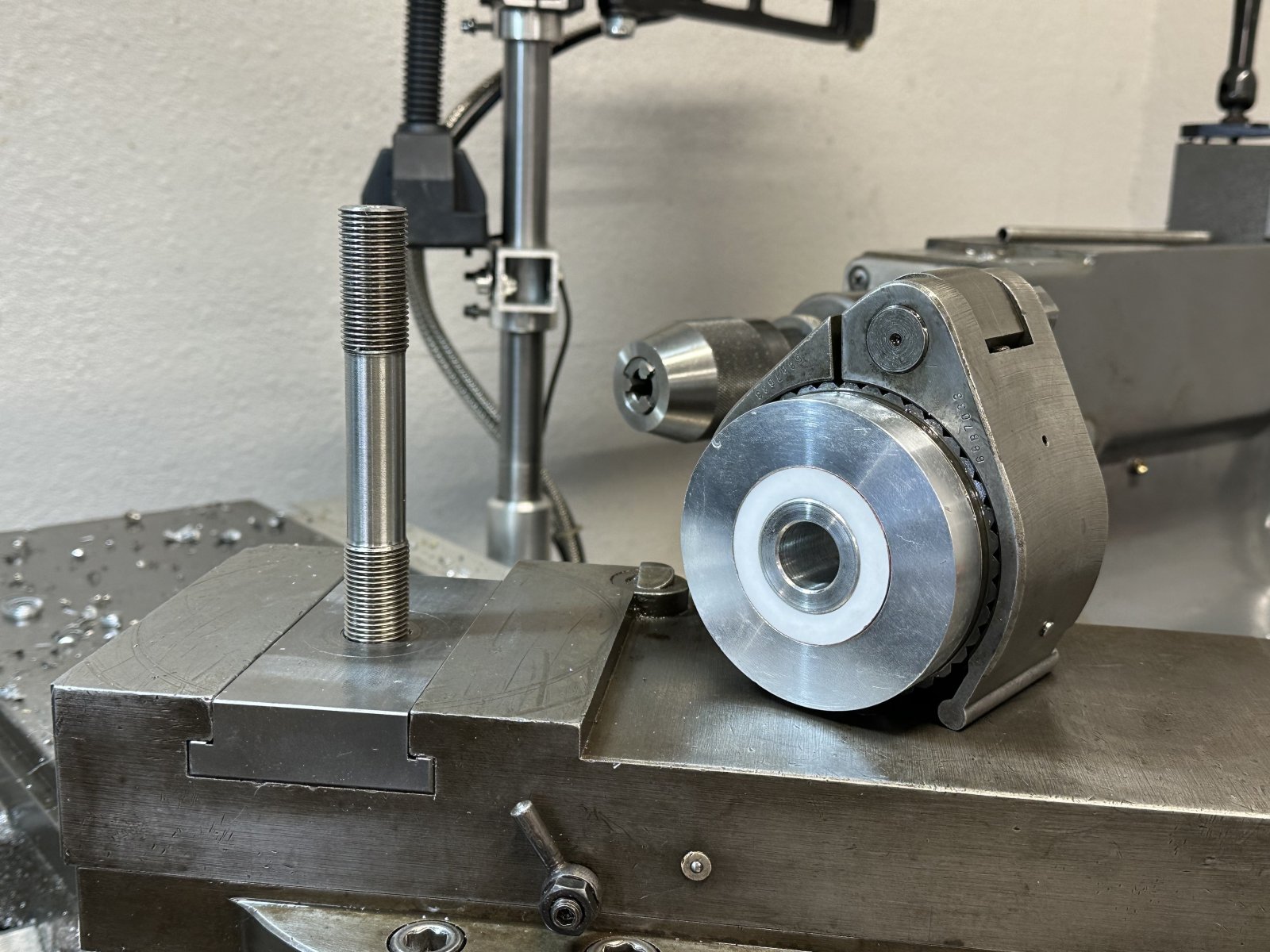

Parts before install:

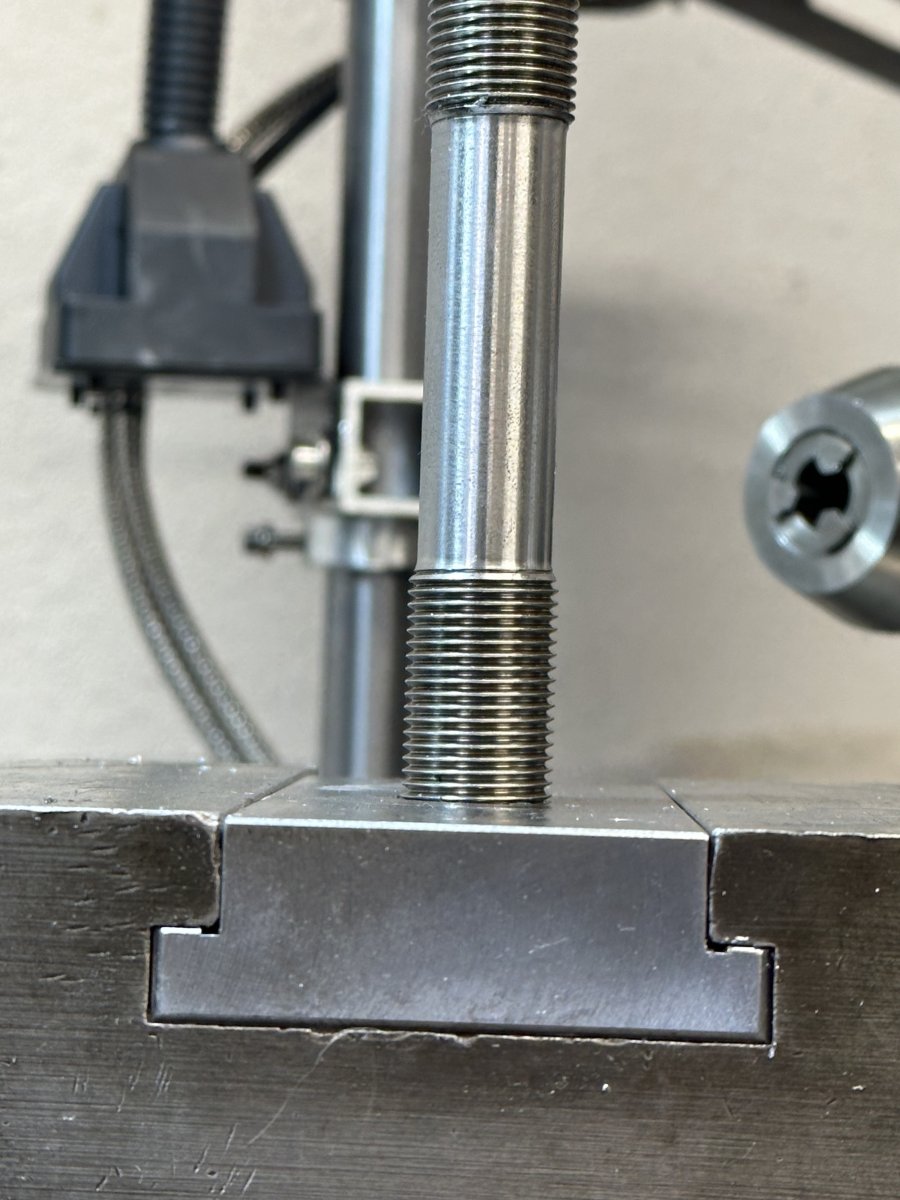

Tradition for lathes sold/made in the US or UK to have a tee slot for the tool post (European and Japanese lathes have a stud for the tool post, no tee slot). Problem with these tee slots, the ends of the tee can break off due to clamp loading of the tee slot. Solution is to cut a slot where the tee nut meets tee slot end. This puts the loading closer to the center or inside of the tee slot greatly reducing the possibility of tee slot breakage or over loading. Keep in mind that stud/nut is torque to just over 200ft/lb.

Installed:

Absolutely excellent lathe in every way.

Bernice

Leveling third try.. there will be more as the lathe and all settles:

Lighting added, DRO display mounting made, tooling some what sorted out, chucks and 5c collet set up made to go, set up the MultiFix B tool post and ...

This is what the MS850 looks like in recent times.

Making a 3/4-16 tpi, B7 chrome-moly steel stud from threaded rod for the Multifix tool post. Un-needed threads are removed with radius ends where the threads meet the center unthreaded area. This is good design to remove what are essentially stress risers (external threads) where not needed. Set up like this:

The turned down section is about 3", diameter variation measures 0.0002" direct off the MS850.

Bottom

Parts before install:

Tradition for lathes sold/made in the US or UK to have a tee slot for the tool post (European and Japanese lathes have a stud for the tool post, no tee slot). Problem with these tee slots, the ends of the tee can break off due to clamp loading of the tee slot. Solution is to cut a slot where the tee nut meets tee slot end. This puts the loading closer to the center or inside of the tee slot greatly reducing the possibility of tee slot breakage or over loading. Keep in mind that stud/nut is torque to just over 200ft/lb.

Installed:

Absolutely excellent lathe in every way.

Bernice