Mark, I think aircraft has standards for stuff like this(?), so these should be good quality terminals.

It looks like those terminals have the double crimp...one on the bare wire and another on the wire's insulation (similar to the sample I pictured above)? Also, do you prefer the terminals with the insulating tube or ones without and heat-shrink them?

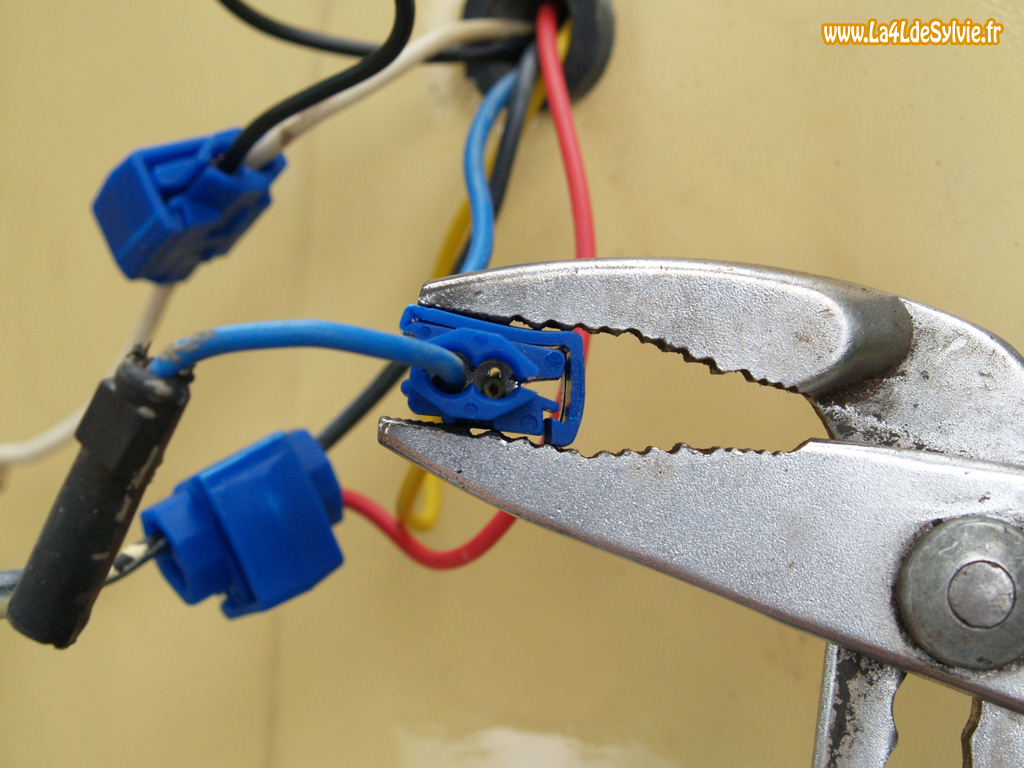

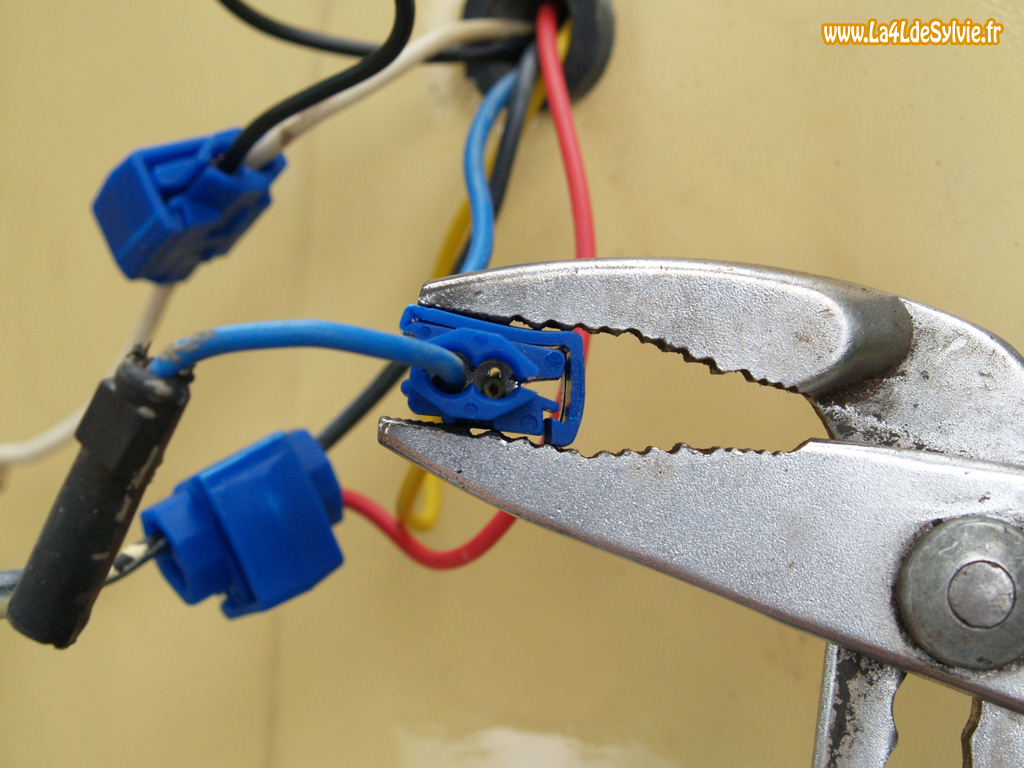

As you say, the crimpers can get expensive. And as you also noted, it seems like most terminals or connectors each use a proprietary style of crimper, so you can end up with a drawer full of them. But I've noticed some that use the separate dies ("jaws") have a selection of interchangeable dies available, so the same tool can be used for many different types of crimps. I'd suggest if possible determine what types of terminals and/or connectors you want to use first, then look for a crimper that has the dies available to fit all (or most) of them. In the long run it will save a lot of money...and keep the drawer from spilling over.

On the subject of connectors (multiple wire plugs), the Molex ones are very affordable and work well. The possible drawbacks are that they are not sealed to protect them in exposed conditions, and the selection gets a bit limited for larger gauge wires. But if you go to the sealed and larger gauge ones they become very expensive. Fortunately the patent for a couple of the 'big name' styles has run out, so they can be found more affordably from other companies.