Steve Thomas

True Classic

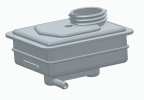

Got overwhelmed by all the things on all the lists I have so decided to get in and do something random  Modeled up the clutch fluid reservoir and printed one. Just in PLA as a draft. The model and an original:

Modeled up the clutch fluid reservoir and printed one. Just in PLA as a draft. The model and an original:

The print and the original:

and the lid fits perfectly!

The outlet is less than perfect. Probably functional after some clean up but not good enough. Then again, this was a draft in the wrong material My machine has two heads so can print a water soluble support material as it prints the real material and I am confident that I can get a perfect outcome. Need to order some decent materials.

My machine has two heads so can print a water soluble support material as it prints the real material and I am confident that I can get a perfect outcome. Need to order some decent materials.

Xref https://xwebforums.com/forum/index.php?threads/brake-fluid-reservoir.45164/post-439732

The print and the original:

and the lid fits perfectly!

The outlet is less than perfect. Probably functional after some clean up but not good enough. Then again, this was a draft in the wrong material

Xref https://xwebforums.com/forum/index.php?threads/brake-fluid-reservoir.45164/post-439732