So this might be a weird one. Hopefully I'm just missing something obvious.

I greatly prefer the look of the round '87+ Climate Control buttons over the older square buttons. So I bought a set and '87+ climate control faceplate thinking it'd be an easy swap - it doesn't seem to be.

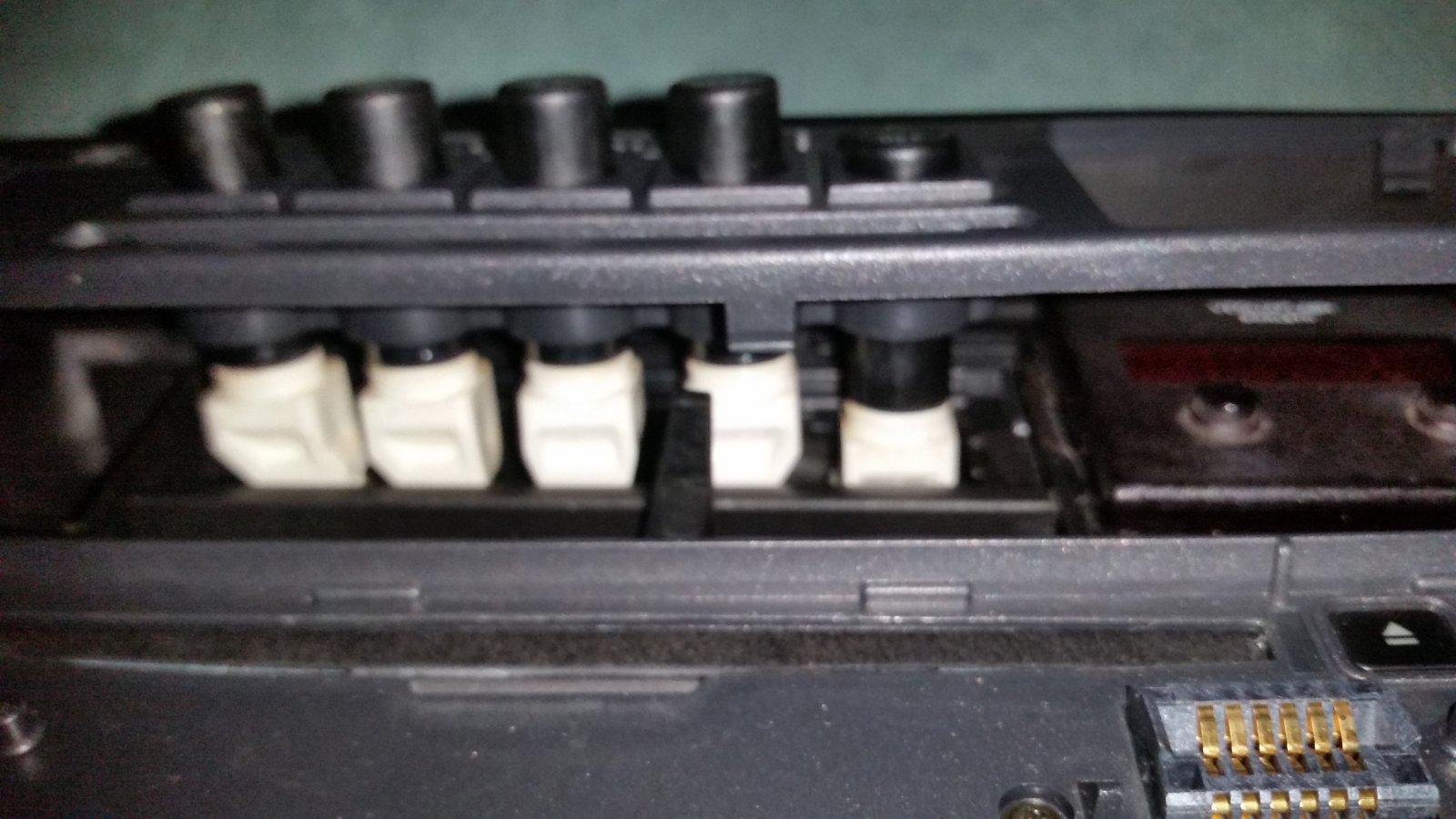

Hopefully the pictures are clear enough for you all to get an idea of what is going on. The round '87+ buttons are considerably longer than the older square buttons and they attach to the ganged switch a little lower. As a result they sit farther forward and lower than the square buttons. Because they sit lower, when a button is pushed to the "on" position, the bottom of the button interferes with the bottom of the black plastic ganged switch enclosure, which angles the button upwards. Look at the "Def" button in the below pic as an example.

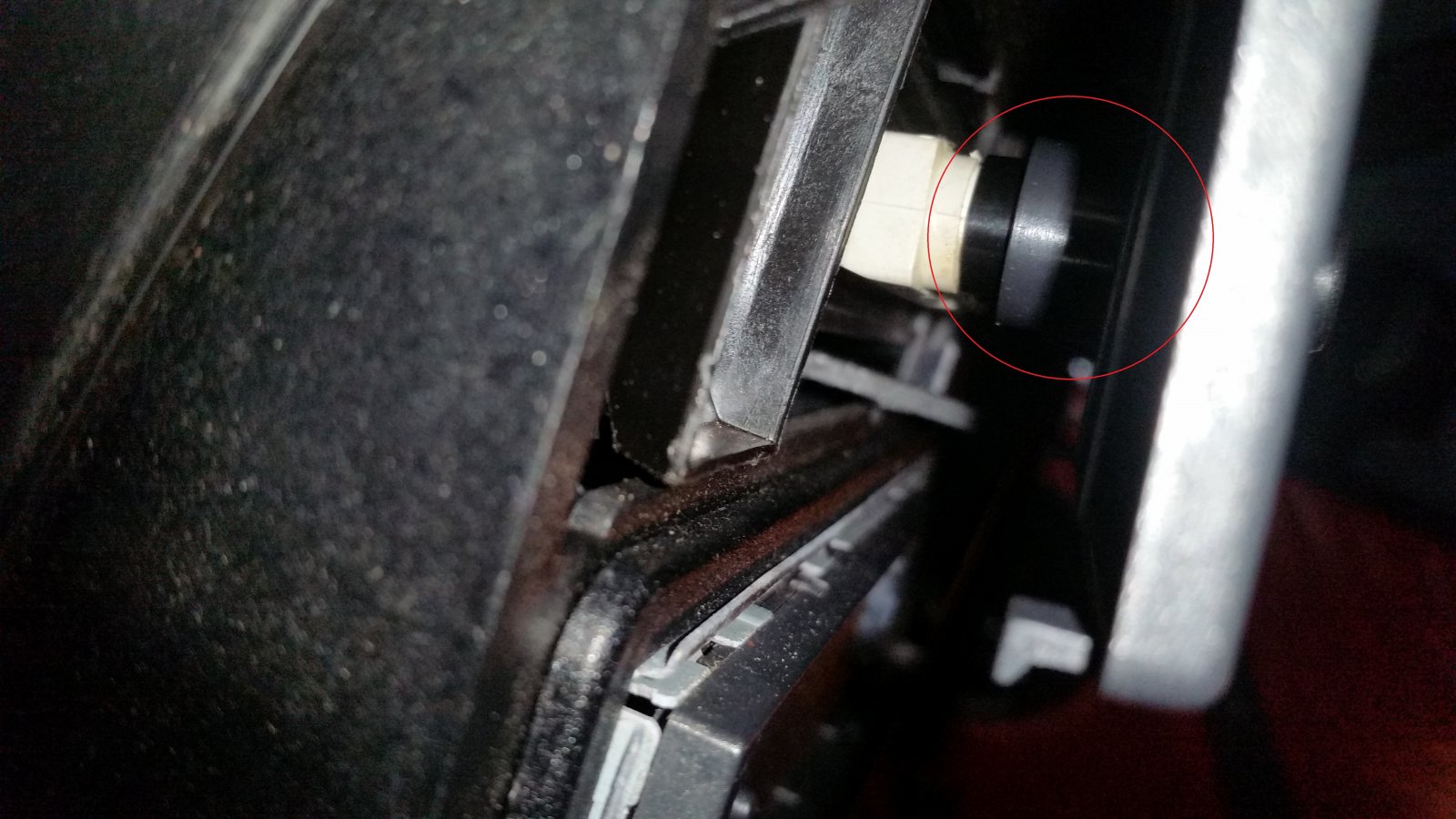

Also, the '87+ faceplate has extruded circular guides on the rear for the buttons which makes it impossible to seat the faceplate with the buttons in their current configuration. See below two pictures. The red circle highlights one of the guides from the side.

So I'm missing something here. I believe either the AC combination switch needs to move backwards, or perhaps the '87+ uses a different radio/climate control/clock frame, combination switch, or something else. MWB lists both of those parts as being compatible with all years from 79 on.

Anyone have any tips? Has anyone done this button swap in the past? Tomorrow I'm planning on tearing this all apart to see if there is a way to mount the combination switch farther back - I want to avoid hacking things. . .

I greatly prefer the look of the round '87+ Climate Control buttons over the older square buttons. So I bought a set and '87+ climate control faceplate thinking it'd be an easy swap - it doesn't seem to be.

Hopefully the pictures are clear enough for you all to get an idea of what is going on. The round '87+ buttons are considerably longer than the older square buttons and they attach to the ganged switch a little lower. As a result they sit farther forward and lower than the square buttons. Because they sit lower, when a button is pushed to the "on" position, the bottom of the button interferes with the bottom of the black plastic ganged switch enclosure, which angles the button upwards. Look at the "Def" button in the below pic as an example.

Also, the '87+ faceplate has extruded circular guides on the rear for the buttons which makes it impossible to seat the faceplate with the buttons in their current configuration. See below two pictures. The red circle highlights one of the guides from the side.

So I'm missing something here. I believe either the AC combination switch needs to move backwards, or perhaps the '87+ uses a different radio/climate control/clock frame, combination switch, or something else. MWB lists both of those parts as being compatible with all years from 79 on.

Anyone have any tips? Has anyone done this button swap in the past? Tomorrow I'm planning on tearing this all apart to see if there is a way to mount the combination switch farther back - I want to avoid hacking things. . .