Alex(Tenerife)

True Classic

So for a long time I have been meaning to tidy up the hoses and fuel/coolant/crank case vent/charge cooler water system. I had been putting it off as it seemed to work.

However since moving to a warmer climate I noticed the swirl pot was getting very warm. Not great,

So I decided to get the refurb done and reinstate a panel between all these gubbins and the hot engine/exhaust/turbo.

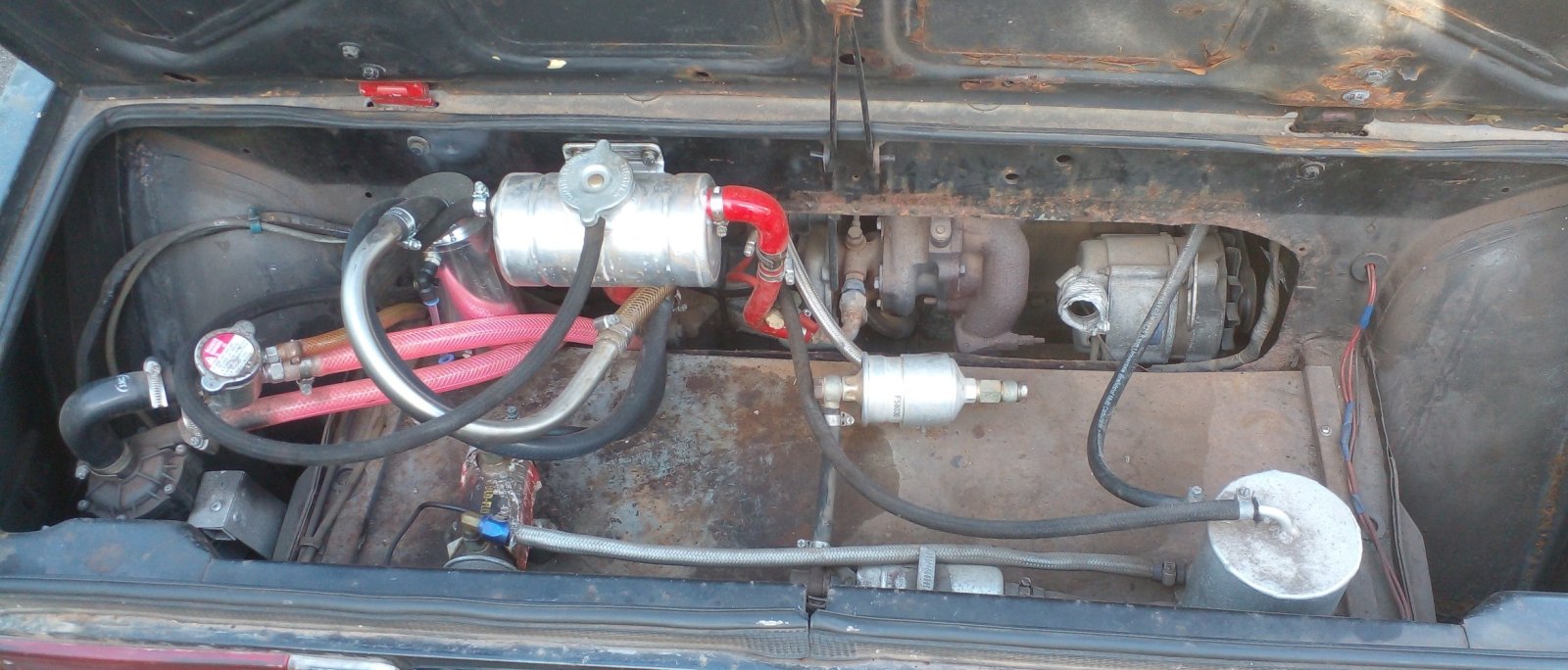

So here is what I started with.

It took 2 templates, first from cardboard and then a second from wood and finally I had a new panel made with 13 holes with grommets. For added protection I also added stick on insulation (foam and foil) on the engine side of the panel.

Also the rust needed treating and painting and I also decided to move the low pressure fuel pump.

Still to do is the wiring. I am going to remake most of it, but I need to make some changes due to moving the fuel pump, so I will take the opportunity to do a tidy up here.

Also the lid needs cleaning and repainting and then I will insulate that too. (Black paint and hot sun so trying to keep heat out).

Once done I plan to run it and see how this changes fuel temp. If it's still too much I will either get an insulating jacket for the coolant tank or box it off (or both).

However since moving to a warmer climate I noticed the swirl pot was getting very warm. Not great,

So I decided to get the refurb done and reinstate a panel between all these gubbins and the hot engine/exhaust/turbo.

So here is what I started with.

It took 2 templates, first from cardboard and then a second from wood and finally I had a new panel made with 13 holes with grommets. For added protection I also added stick on insulation (foam and foil) on the engine side of the panel.

Also the rust needed treating and painting and I also decided to move the low pressure fuel pump.

Still to do is the wiring. I am going to remake most of it, but I need to make some changes due to moving the fuel pump, so I will take the opportunity to do a tidy up here.

Also the lid needs cleaning and repainting and then I will insulate that too. (Black paint and hot sun so trying to keep heat out).

Once done I plan to run it and see how this changes fuel temp. If it's still too much I will either get an insulating jacket for the coolant tank or box it off (or both).