Eugene Harvey

True Classic

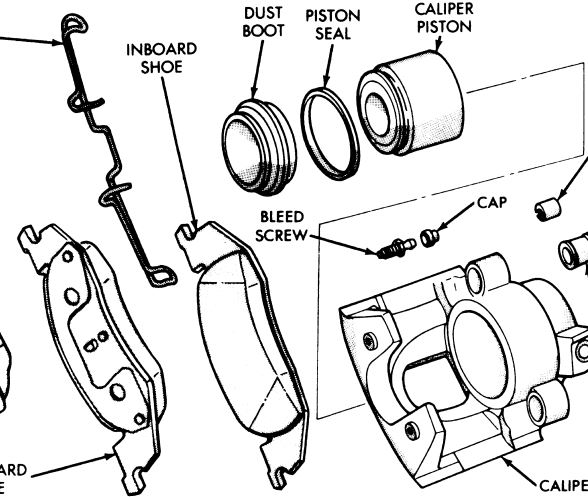

I'm beginning to think I'm missing something as I've rebuilt a few calipers, as well as master and slave cylinders in the past and it's been a pretty straight forward process. There are generally only 3 components, the cylinder, the piston and the seal. The piston has a tightish fit, but basically holds the seal in place, which as long as the cylinder walls are clean and smooth (without scoring or pitting - which the honing tool is require to fix) creates a fluid tight seal. So fixing a leaky cylinder is just replacing the seal and boot.

Where you have a locked up brake caliper, it is corrosion, simple as that. So a slightly more comprehensive rebuild is required, which is first removing the piston, tidying that up, and even with some pitting on the piston isn't a major, as it's the seal that is important. The big issues is the condition of the cylinder, as that needs to be restored to as smooth as possible (no scoring or pitting), if the cylinder is heavily scored, you need a new caliper.

(edit) Looking at the price, if the piston is even slightly dodgy, I'd just stump up and buy new ones. Add in Seals and Boots at $9 a pair and you only need to worry about the caliper.

Where you have a locked up brake caliper, it is corrosion, simple as that. So a slightly more comprehensive rebuild is required, which is first removing the piston, tidying that up, and even with some pitting on the piston isn't a major, as it's the seal that is important. The big issues is the condition of the cylinder, as that needs to be restored to as smooth as possible (no scoring or pitting), if the cylinder is heavily scored, you need a new caliper.

(edit) Looking at the price, if the piston is even slightly dodgy, I'd just stump up and buy new ones. Add in Seals and Boots at $9 a pair and you only need to worry about the caliper.

Last edited: