fiatfactory

Steve Cecchele

A regular run of the mill 1.6 sohc 8 valve engine uses a multi rib drive belt... the parts will all interchange with a regular run of the mill 1500 sohc

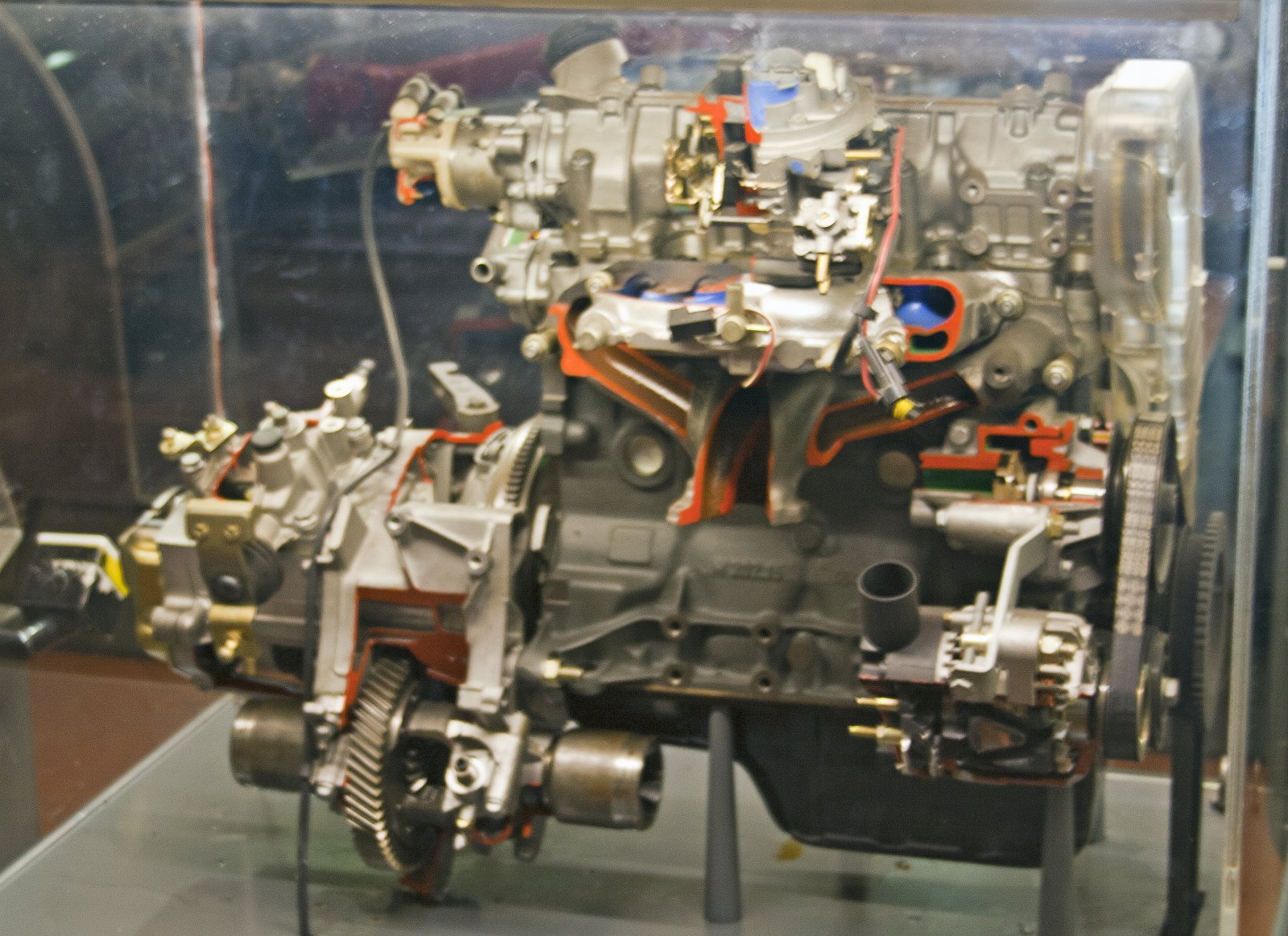

grainy, but large cutaway pic of a 1581cc sohc, showing drive belt/pump/alternator and tensioner...

grainy, but large cutaway pic of a 1581cc sohc, showing drive belt/pump/alternator and tensioner...