KBabcock

True Classic

This post was created to help new users and some old ones understand and adjust their shift linkage to eliminate shifting issues. Please note this will cover the most common problems which will solve most issues for most X owners but you may have problems beyond the scope of this post with the transmission. Either way this is where you need to start.

The shift linkage is relatively simple and is covered in the service but from my own experience it leaves lots of details out and can cause a level of confusion or doubt. I will attempt to eliminate that doubt and allow you to tackle the problem with confidence. So, let’s get started.

Generally, there are two types of shift issues you will encounter. One is being unable to enter a gear or fine it and the other is a jumping out of gear once you enter it. This can be broken down into two categories. One, front to rear shifting (1 to 2, 3 to 4 and 5 & reverse) The other is side to side engagement issues (ie get to 1st and 2nd or 5th and reverse).

Shift issue front to rear (Jumping out of gear or not engaging)

We will start with back and forth issues. In my own experience I was shifting the car from 1st to 2nd and it would go in fine but then after a second or two it would pop out of 2nd, my first thought was a transmission issue. As it turned out, to my relief, it was a simple shift linkage adjustment to resolve the issue.

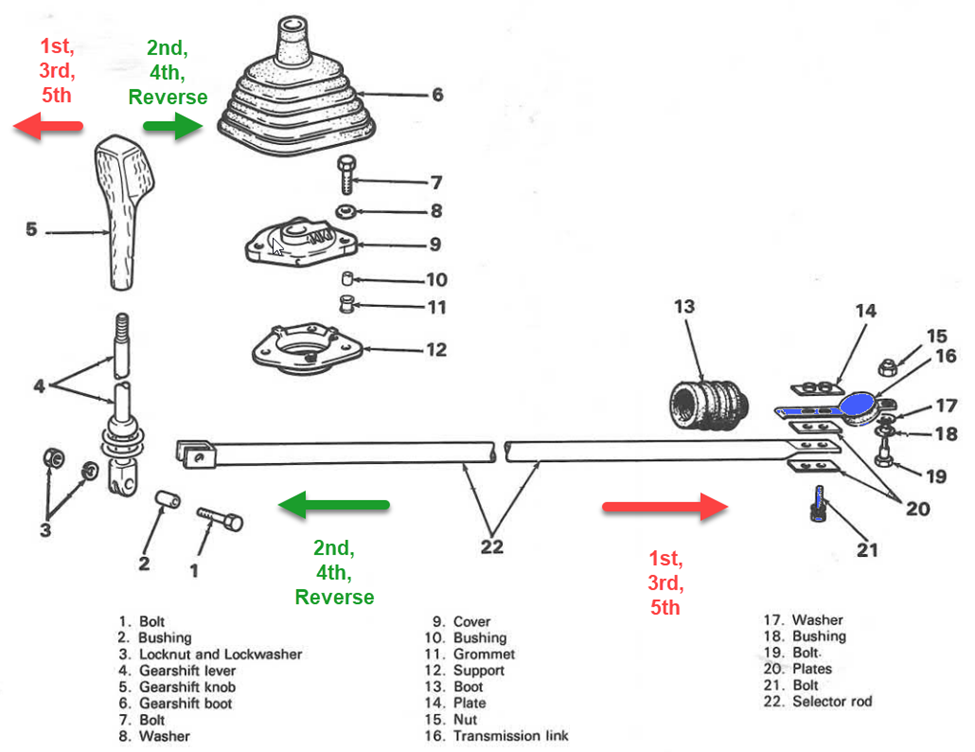

Because it was coming out of second gear it was due to the gear not being completely engaged. If you look at the diagram below you can see that when pulling the shifter back into second it moves the shift linkage forward (#22 selector rod and attached components) this in turn pulls the selector rod on the transmission forward. The fact that 2nd was popping out indicated the gear selector was not fully engaged because the shift linkage was a little too long and not allowing the gear for full engage. I had to make the shift linkage a little shorter to allow full engagement.

First thing to understand is that small adjustments in the shift linkage have big impact on shifter movement. A 1/8” or ¼” movement of the shift linkage pushes a internal transmission level arm which translated that movement to 1” to 2” movement of the gear, this is an example and may not be completely accurate with the actual amount of movement in the trans. So never doubt that small adjustments will have a big effect.

Now to adjust this look at the lollipop (#16 Transmission linkage, Blue colored in diagram) and look at the bolts #21 (diagram only shows one of the two bolts) It has two ovals bolt holes that allow it to adjust as can be seen in the picture below. Again small movements have big results. The ovals only allow ½” of movement back and forth. So a bit of adjustment then testing will be required to resolve the shift issue. You will need to loosen both bolts then slide the rods back or forth. Note the nuts for these bolts are welded to the top plate so you only need to worry about the bolts. Also keep in mind that the adjustment will not only affect the gear your having troubles with but will affect the gear forward or aft of it. While I was adjust 2nd gear it was having an effect on first gear, so only adjust in minor increments. When set properly both gears should work fine.

Shift issue side to side (Not able to find 1st & 2nd or 5th & reverse)

The second issue is side to side shifting, moving the shifter from the neutral position to engage 1st & 2nd or 5th and Reverse. I also had this issue where my car was not able to go into reverse without considerable attempts. Again, I feared that I had transmission issues but again that was not the case.

Most issues with getting into reverse are due to too much slop in the bushing assembly that connects the lollipop to the transmission shift lever. There is no factory adjustment for the side to side shift issues so getting rid of the slop is the goto solution.

My first recommendation when having issues here is replacing the Bushing assembly (In the diagram above part #s 15,17,18,19) They are sold as a unit by several vendors. I picked mine up from MidWest Bayless at $8.75, it is foolish not to replace these. Also, only replace them as a unit, never mix and match pieces. The tolerances are so tight that parts not meant to work together can cause you real problems with too much slop, ask me how I know this. Below are two different bushing from two sets, notice the difference in heights, mixing these parts can have a profound effect on the slop in the wave washer area. If your lollipop looks old and beat I would replace that as well, again cheap and easily obtained and can cause slop on the shift linkage.

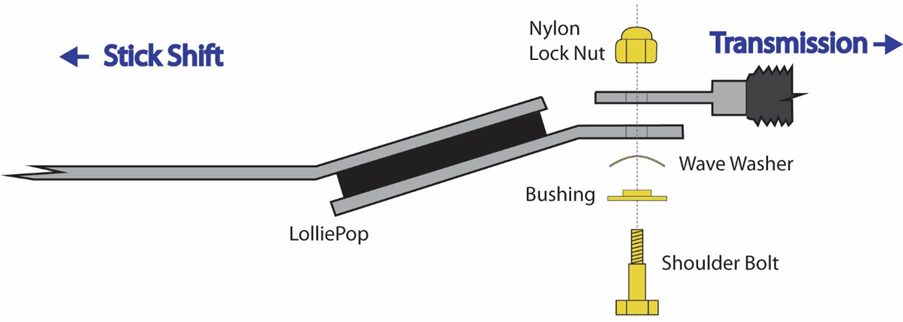

The key is the space the wave wash lives in. See diagram below to see how this is assembled.

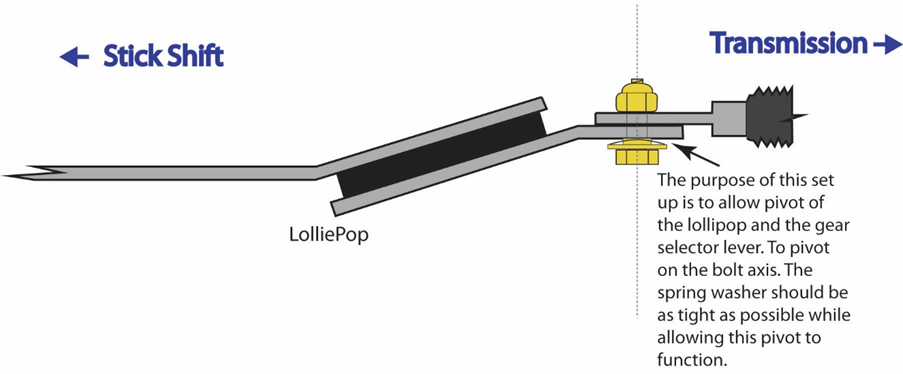

Below is a picture of the assembly that I just installed on my car and it corrected the shifting issue. The wave washer looks flattened out in this picture but it has a little bit of clearance for movement. You can see the slightest of gaps of the wave washer if you look carefully. It can still pivot but has very little slop in the assembly. Before this when I would have someone shift in the car as I watched below the wave washer would absorb the movement and the gear shifter would not move. Now there is almost no flex in the wave washer but it can still pivot. The shifter works well now. Please note to NEVER try and force a gear shift, especially into reverse. You are likely to bend inter transmission components then you have real problems. Alway gentle is the way to go.

Note, I have heard of some users putting a thin regular washer with the wave washer when there was too much slop to correct the problem. I can see this working but you have to be careful to make sure you still have enough clearance for the wave washer to allow rotation around the bolt, if it can't flex you will be creating a situation for bigger problems and repairs. It's best to just replace the assembly.

Again little movements have big impacts. When I move the shifter lever, now that it works, the transmission input shaft only moves about a ¼” to 3/8" at the edge of the gear selector lever as it rotates. That was all it took to access 5th and Reverse gears.

Note: When putting the bushing assembly on, the nut is a nylon lock nut and does not need to be torqued down. If you try to, you will likely snap the bolt. I recommend using a 3/8” drive but palm the head and twist, do not use the handle, this will prevent you from tightening too tight. It just needs to be snug.

Last Resort fix for Side to Side

The above will fix most people’s issues but if you still have issues with the side to side shift you may have a twisted selector rod. If this is the case you will need to replace the rod or you could twist the lollipop surface where it connects to the gear shift selector lever to compensate for twist in the rod. This can be done with a plier and the lollipop in a vise.

Note: the above part was my old lollipop and I did not need to do this to fix my car. I did this as a simple example for others.

Now there could be an issue with the shifter as there are some bushing at the stick shift but from what I have researched this is very rare but if you exhausted the above you may want to replace them. I do not have experience here so someone else will need to ad that section.

I will update this as new advice or ideas are brought by member with far more experience then myself.

The shift linkage is relatively simple and is covered in the service but from my own experience it leaves lots of details out and can cause a level of confusion or doubt. I will attempt to eliminate that doubt and allow you to tackle the problem with confidence. So, let’s get started.

Generally, there are two types of shift issues you will encounter. One is being unable to enter a gear or fine it and the other is a jumping out of gear once you enter it. This can be broken down into two categories. One, front to rear shifting (1 to 2, 3 to 4 and 5 & reverse) The other is side to side engagement issues (ie get to 1st and 2nd or 5th and reverse).

Shift issue front to rear (Jumping out of gear or not engaging)

We will start with back and forth issues. In my own experience I was shifting the car from 1st to 2nd and it would go in fine but then after a second or two it would pop out of 2nd, my first thought was a transmission issue. As it turned out, to my relief, it was a simple shift linkage adjustment to resolve the issue.

Because it was coming out of second gear it was due to the gear not being completely engaged. If you look at the diagram below you can see that when pulling the shifter back into second it moves the shift linkage forward (#22 selector rod and attached components) this in turn pulls the selector rod on the transmission forward. The fact that 2nd was popping out indicated the gear selector was not fully engaged because the shift linkage was a little too long and not allowing the gear for full engage. I had to make the shift linkage a little shorter to allow full engagement.

First thing to understand is that small adjustments in the shift linkage have big impact on shifter movement. A 1/8” or ¼” movement of the shift linkage pushes a internal transmission level arm which translated that movement to 1” to 2” movement of the gear, this is an example and may not be completely accurate with the actual amount of movement in the trans. So never doubt that small adjustments will have a big effect.

Now to adjust this look at the lollipop (#16 Transmission linkage, Blue colored in diagram) and look at the bolts #21 (diagram only shows one of the two bolts) It has two ovals bolt holes that allow it to adjust as can be seen in the picture below. Again small movements have big results. The ovals only allow ½” of movement back and forth. So a bit of adjustment then testing will be required to resolve the shift issue. You will need to loosen both bolts then slide the rods back or forth. Note the nuts for these bolts are welded to the top plate so you only need to worry about the bolts. Also keep in mind that the adjustment will not only affect the gear your having troubles with but will affect the gear forward or aft of it. While I was adjust 2nd gear it was having an effect on first gear, so only adjust in minor increments. When set properly both gears should work fine.

Shift issue side to side (Not able to find 1st & 2nd or 5th & reverse)

The second issue is side to side shifting, moving the shifter from the neutral position to engage 1st & 2nd or 5th and Reverse. I also had this issue where my car was not able to go into reverse without considerable attempts. Again, I feared that I had transmission issues but again that was not the case.

Most issues with getting into reverse are due to too much slop in the bushing assembly that connects the lollipop to the transmission shift lever. There is no factory adjustment for the side to side shift issues so getting rid of the slop is the goto solution.

My first recommendation when having issues here is replacing the Bushing assembly (In the diagram above part #s 15,17,18,19) They are sold as a unit by several vendors. I picked mine up from MidWest Bayless at $8.75, it is foolish not to replace these. Also, only replace them as a unit, never mix and match pieces. The tolerances are so tight that parts not meant to work together can cause you real problems with too much slop, ask me how I know this. Below are two different bushing from two sets, notice the difference in heights, mixing these parts can have a profound effect on the slop in the wave washer area. If your lollipop looks old and beat I would replace that as well, again cheap and easily obtained and can cause slop on the shift linkage.

The key is the space the wave wash lives in. See diagram below to see how this is assembled.

Below is a picture of the assembly that I just installed on my car and it corrected the shifting issue. The wave washer looks flattened out in this picture but it has a little bit of clearance for movement. You can see the slightest of gaps of the wave washer if you look carefully. It can still pivot but has very little slop in the assembly. Before this when I would have someone shift in the car as I watched below the wave washer would absorb the movement and the gear shifter would not move. Now there is almost no flex in the wave washer but it can still pivot. The shifter works well now. Please note to NEVER try and force a gear shift, especially into reverse. You are likely to bend inter transmission components then you have real problems. Alway gentle is the way to go.

Note, I have heard of some users putting a thin regular washer with the wave washer when there was too much slop to correct the problem. I can see this working but you have to be careful to make sure you still have enough clearance for the wave washer to allow rotation around the bolt, if it can't flex you will be creating a situation for bigger problems and repairs. It's best to just replace the assembly.

Again little movements have big impacts. When I move the shifter lever, now that it works, the transmission input shaft only moves about a ¼” to 3/8" at the edge of the gear selector lever as it rotates. That was all it took to access 5th and Reverse gears.

Note: When putting the bushing assembly on, the nut is a nylon lock nut and does not need to be torqued down. If you try to, you will likely snap the bolt. I recommend using a 3/8” drive but palm the head and twist, do not use the handle, this will prevent you from tightening too tight. It just needs to be snug.

Last Resort fix for Side to Side

The above will fix most people’s issues but if you still have issues with the side to side shift you may have a twisted selector rod. If this is the case you will need to replace the rod or you could twist the lollipop surface where it connects to the gear shift selector lever to compensate for twist in the rod. This can be done with a plier and the lollipop in a vise.

Note: the above part was my old lollipop and I did not need to do this to fix my car. I did this as a simple example for others.

Now there could be an issue with the shifter as there are some bushing at the stick shift but from what I have researched this is very rare but if you exhausted the above you may want to replace them. I do not have experience here so someone else will need to ad that section.

I will update this as new advice or ideas are brought by member with far more experience then myself.

Last edited: