Hard start relay

This is from another thread originally and a will be a ‘how to’ I will get around to doing. This was done on a FI car so yours will be a little different and involve one less wire.

The starter relay is more involved in regards to what you need to do and requires unwrapping the loom in the spare tire well to pull out an existing wire which you will use in two ways. You will be adding a wire to carry power from the main lug of the starter to the new relay and of course adding a grounding wire.

You will need:

- One inline crimp splice connector with heat shrink - 12-10 AWG Clear Seal Heat-Shrink Butt Splice Terminal (not a big fan of these but its what you need)

- One 10mm ring crimp connector for 10ga wire

- One 8mm ring crimp connector for 12-16ga wire

- Two locking female spade connectors for 10ga wire to go into a relay base

- Two locking female spade connectors for 16ga wire to to into a relay base

- One relay base

- One relay, normally open 4 pin 35amp with diode. This is the same relay you used for the low beams.

- 3’ of 12 or 16ga wire, I use black for ground and red for power

- 3’-4’ of 10ga wire, I used red

- Nice to have is a fuse holder for a 30 amp fuse which accommodates 10ga wire. The existing circuits are not fused, if you feel confident about your work then don’t use a fuse in the power supply wire or choose a relay which has a fuse holder built into it. Like these (but buy a name brand):https://www.amazon.com/Nilight-50023R-Automotive-Wires-Auto-Switches/dp/B07PK7F1MC/ref=sr_1_4?crid=27FD6HTCRQL2P&keywords=Fused+relay&qid=1658089056&s=automotive&sprefix=fused+relay,automotive,122&sr=1-4

Remove both the positive and negative terminals/wires from the car battery.

The starter has four wires to it if it is fuel injected. The main lug of the starter has two wires, a very heavy red one which brings power from the battery, a medium thick black one which carries power from the alternator to the starter (and is how the power is carried back to the battery from the alternator.) There are two wires to the solenoid, one from the ignition switch and the other to the double relay (1979/80 carb cars may have a second wire as well due to emissions equipment ). An early X will have only one wire to the solenoid coming from the ignition switch.

For a Fuel Injected X, the starter solenoid as two wires, one red and one red with a black stripe, which are crimped onto a single female spade terminal which goes to the starter solenoid male spade terminal. The all red wire is 10ga and comes from the ignition switch, carrying power to the solenoid to engage the starter when you turn the key to the start position. The second wire is 12ga red with a black stripe, this carries power back to the double relay to cause the double relay to run the fuel pump when the starter is running. An early carbureted car will not have the second wire going back into the loom as there is no double relay.

Unplug the paired red wires from the starter solenoid, do not do anything to this connector you will be using this exactly as is. Loosen and remove the nut on the starter main lug holding the large red wire and the black wire.

What you will be doing is making a new 10ga wire which will have a ring terminal on one end to be added to the wires on the main starter lug and a female locking spade on the other end to go into the relay holder. This will bring always hot power to the starter relay. You will make a 8” long 12-16ga wire with a locking female terminal on one end and a ring crimp connector on the other end to be the ground for the relay.

Ok now for the fun part.

This is easiest if you remove your passenger seat and the cover for the spare tire area. To remove the seat, take a 6mm allen key (I think its 6) and slide the seat all the way back. Under the front of the seat you will see the seat slides, there is a allen socket head fastener there. Loosen the fasteners (one at the front of each track) a number of turns so the seat can be lifted just a bit, you don’t have to take the fasteners out but if you want to do a bunch of tedious work with your Allen key go for it, I am lazy). Now slide the seat all the way forward, you will see two Philips screw heads, undo these completely. As they go all the way through the floor pan of the car you might go under head the spray some lubricant on them to make them come out easier. You might also consider a hammer drill if they are at all recalcitrant. Once the two screws are removed you can slide the seat forward about half an inch and lift up on the front of the seat and the allen bolts will come through the keyhole slots and you can remove the seat completely.

Remove the spare tire cover by removing the philips screws holding the black metal bracket holding the vinyl cover in place. Remove the spare tire. Remove the clamp connector holding the 5/8” heater supply hose to give yourself some more room.

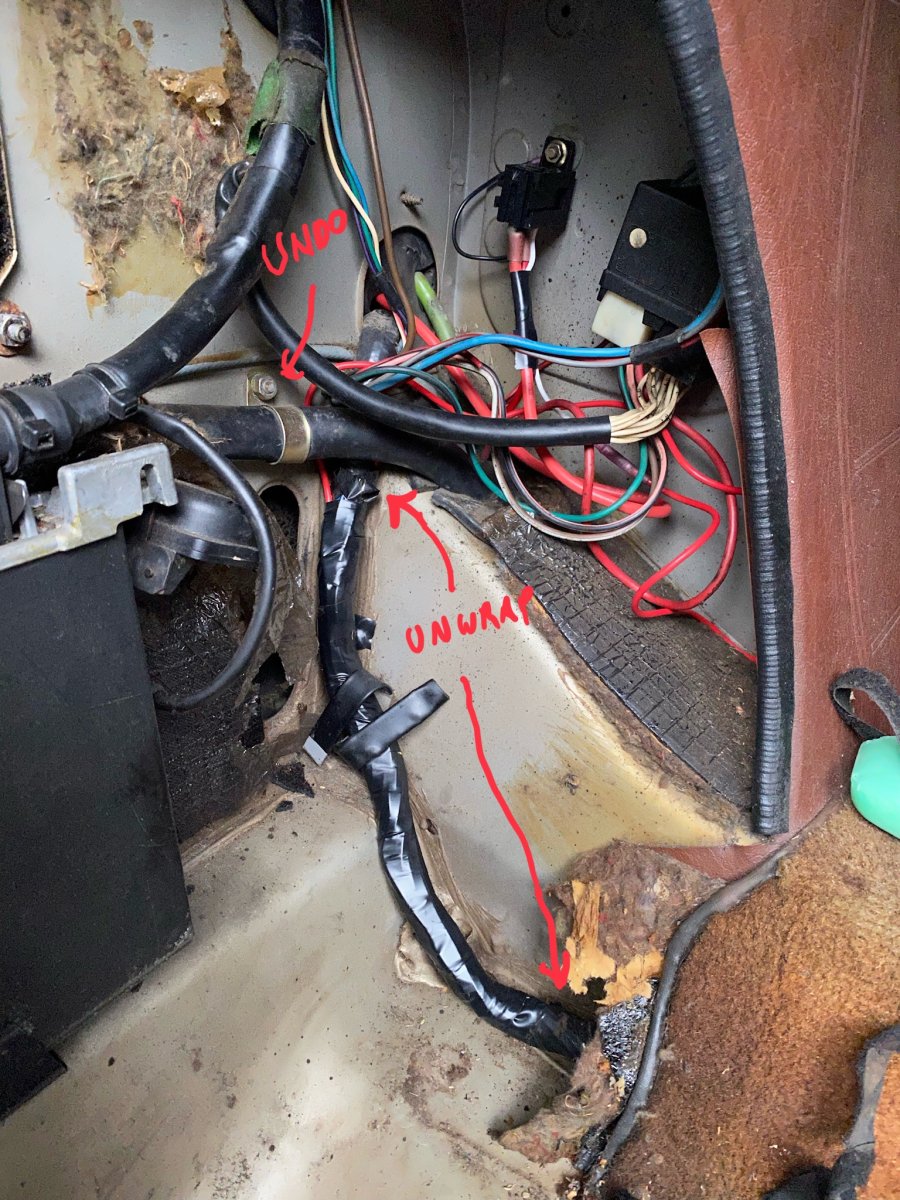

Along the tunnel you will see a thick wire bundle wrapped in tape. There are a few bent over metal retainers in the spare tire area you will bend out of the way. Up above you will see the double relay which has the its own wiring, you won’t be touching that, there is also a second relay which runs the FI injector cooling fan, again you won’t be touching that unless you want to (I moved mine up higher so I could use the threaded stud to mount my new relay).

Take an 18” length of red 12-16ga wire and crimp a locking female spade connector at one end to go into the relay holder. The other end your will be eventually crimping the inline connector to it and the red 10ga wire coming from the ignition switch.

Pull the wire bundle out and carefully slit the electrical tape covering, starting at the floor and going up to just above the top of the tunnel. Buried in the bundle is a 10ga red wire, this is the wire running from the ignition switch to the starter solenoid. Pull it out of the bundle so you can access the 10ga wire near the floor. If you are not confident you have the right wire you can test for continuity by testing between the 10ga wire you have found and the red with black leader wire going into the double relay, as these wires are connected at the female spade connector they will have continuity when tested. If you have a steel pin you can pierce the insulation touch your meter to and then poke the other probe into the bottom of the double relay connector where the red with black leader wire goes into it to ensure the wires are connected at the female spade connector at the starter.

You will be cutting this wire to bring a wire to the relay to switch the relay “on“. You will cut the wire, apply an inline connector, crimp it to the 10 ga wire on one side, then crimp in an 24-36” length of 12-16ga wire and apply heat to seal the crimped connector to the wires (10ga on one side of the connector and 12-16ga on the other). I say this so that you consider the cut carefully as you will be down in the corner and access won’t be good. You are trying to maximize the amount of the 10ga wire you will be using to go from the new relay to carry power to the starter solenoid and still be able to work with what is sticking out of the harness at the floor. I cut mine such that I had 1.5” of the wire sticking out of the harness to crimp the 12-16ga wire to the 10ga wire coming from the ignition switch.

FYI, have a fire extinguisher handy when you use heat or flame on the crimp connector, the sound insulation is very flammable. It is bad form to burn your car down while heating heat shrink tubing…

OK so now you have a length of 10ga red wire coming from the firewall side and the 12-16ga red wire you just crimped onto the wire coming from the ignition switch. Pull the 10ga up out of the bundle to where it goes into the bundle where it goes through the firewall into the engine bay.

Weave the 12-16ga wire into the wire bundle such that it will thenemerge where the 10ga wire goes into the engine bay and wrap the bundle in electrical tape leaving the 10ga wire and the 12-16ga wire coming out at the top of the tunnel to be able to go to your new relay. For my new relay I used the threaded stud the FI fan relay was attached to and moved that one up with a new fastener (I used a short sheet metal screw, the gas tank is behind that wall so it was a notably short screw).

Now crimp on the locking female spade to the 10ga wire and insert it into the relay holder in the 87 position (you should have enough slack in the wire to place the relay on the existing threaded stud for the fan relay). Insert the red 12-16ga wire with connector into the 85 position. The wire with the other ring connector will go on the threaded stud (use a toothed washer to ensure good ground) and the locking female connector into the 86 position of the relay holder.

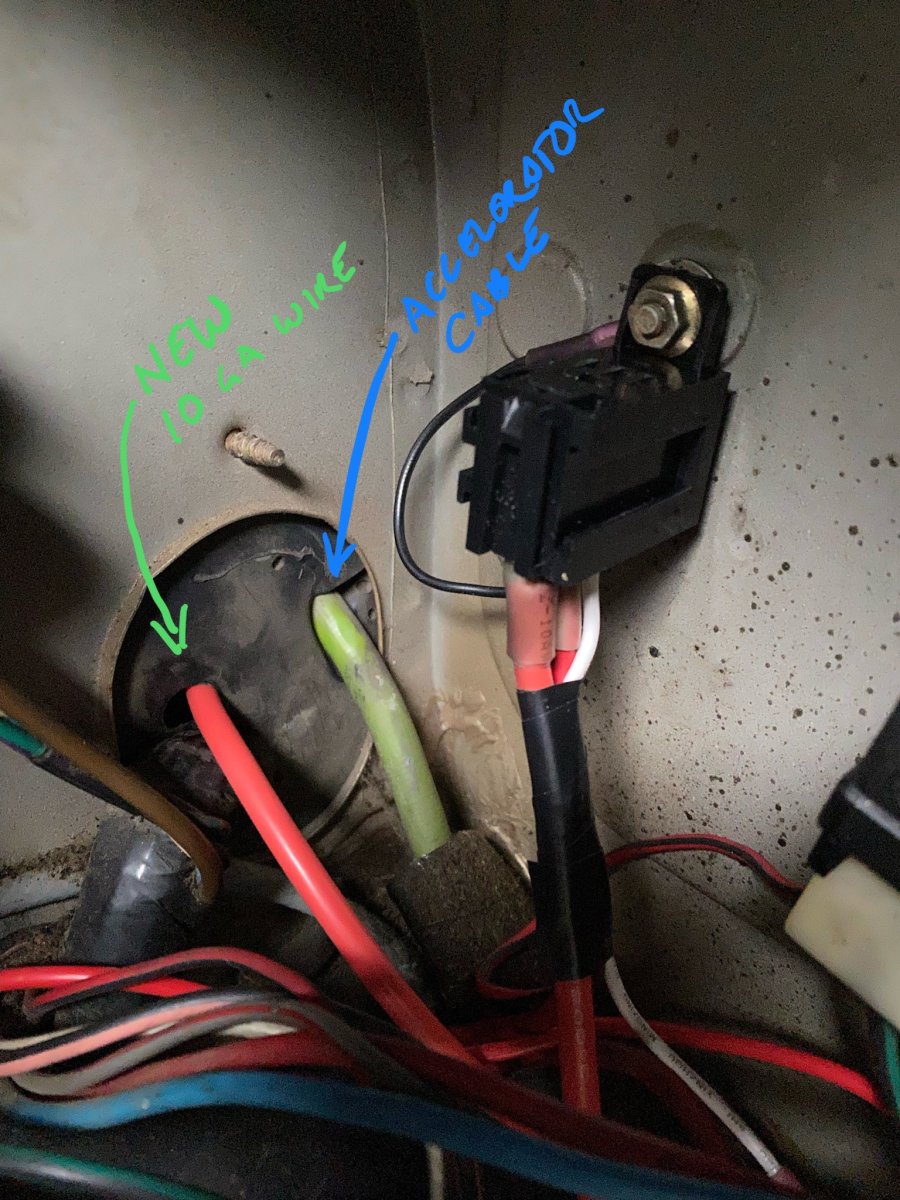

For the power wire I crimped on the 10mm ring connector to the 10ga wire. Pushed the 10ga wire with the ring connector on it through the black flap where the acclerator cable goes into the engine bay. I then put together the new wire with the existing large red wire and the black wire onto the main lug of the starter. Make sure you feed the new 10ga wire into the rubber boot so it is protected along with the other wires. Fix the new red wire to other wires leading up to the flap into the spare tire area such that it doesn’t foul on anything but has enough slack for engine movement and for when/if you have to replace your starter. I left an extra loop in the spare tire compartment so it can be pulled a bit into the engine bay if needed. The new red wire will go into the relay’s 30 position.

Back in the spare tire compartment I trimmed the new 10ga power wire to easily reach the relay position, crimped on the female spade and inserted it into the relay holder 30 position

Install the relay, attach the battery, put the spare tire cover back on, put the spare back in and reinstall the passenger seat.

For those looking carefully at my pic you will notice I did mine on this car slightly differently. The PO, who I dislike mightily, had used a wire tap to reinstall the red wire with black leader to the main red wire at the solenoid spade connection. This had caused intermittent starting issues in the past so on my install I cut the red with black leader wire in the spare tire compartment and crimped it onto the red wire at the relay 87 position. The exact way this is done will change a bit in the future as I used some parts I had on hand to do this and it is less than ideal (cheap relay holder with cheapo connectors, all the things I say not to do…) as I only found the PO’s handiwork when replacing the coolant hoses. The wires will get some future tidying so it is a bit less of a rats nest with extra wire length.