tvmaster

True Classic

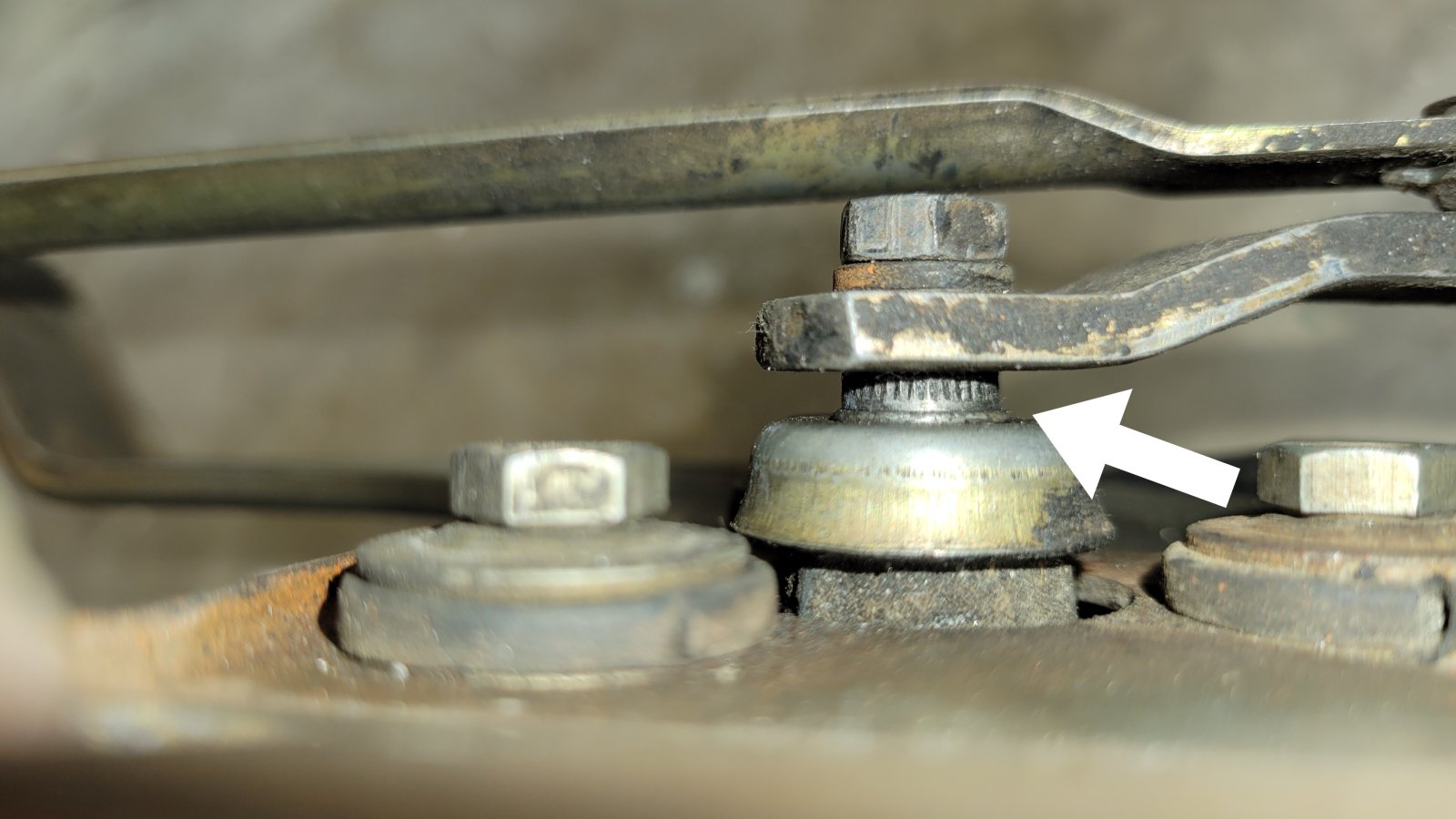

Re-assembling my '74 wiper mechanism assembly, and am making one, better mechanism from the two I have, but this part (arrows) doesn't seem to want to go back down all the way. Have tried various methods of pressure and lubrication, but the splines on the bottom, If I recall from before disassembly, shouldn't be visible.

Any idea how to get the arm to press down fully on the post spline?

Any idea how to get the arm to press down fully on the post spline?