jvandyke

True Classic

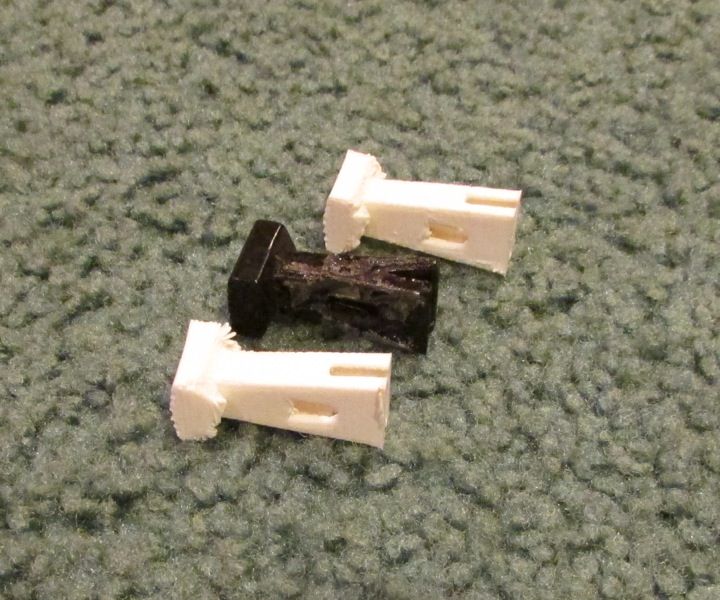

Going to try printing a heater knob.

Not much confidence as the part is small and detail is fine and I don't know what I'm doing. Used Sketchup to model the part. I've used sketch up a little and taught it to some of my elementary students but until you have a concrete goal, the motivation to dig deep wasn't there. I've learned a ton in a couple days tinkering. I thought a thread on it would be fun.

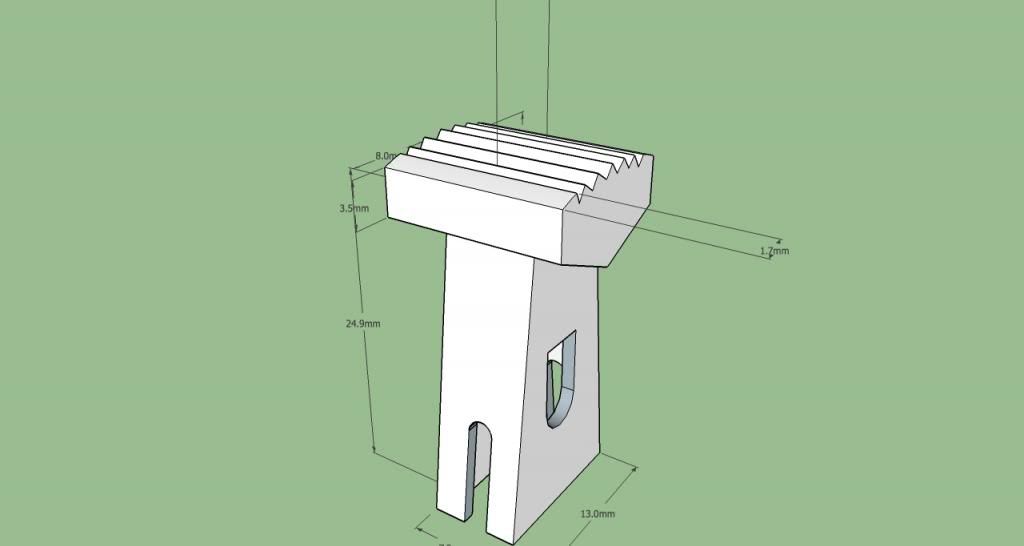

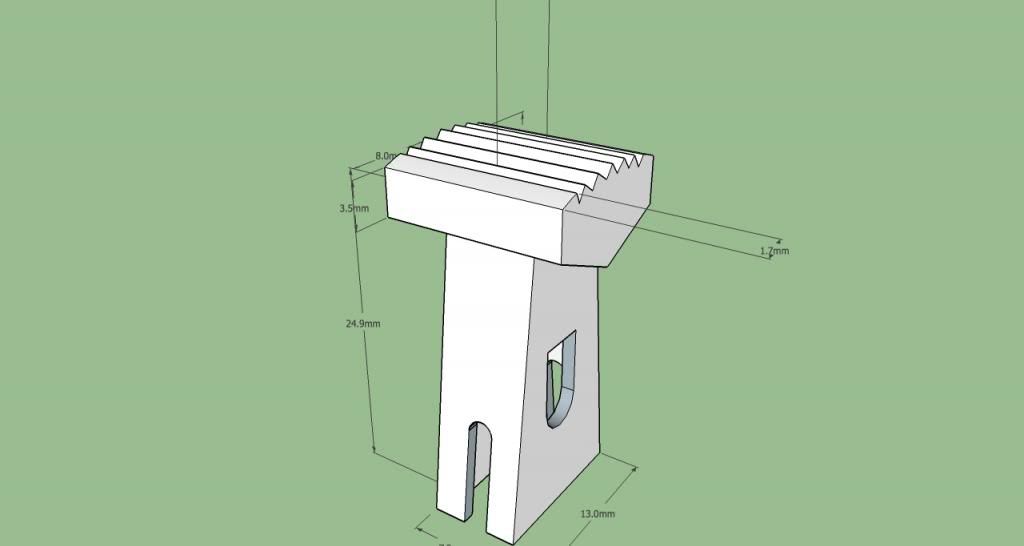

Here's the latest version. Accurate on "paper".

Not much confidence as the part is small and detail is fine and I don't know what I'm doing. Used Sketchup to model the part. I've used sketch up a little and taught it to some of my elementary students but until you have a concrete goal, the motivation to dig deep wasn't there. I've learned a ton in a couple days tinkering. I thought a thread on it would be fun.

Here's the latest version. Accurate on "paper".