You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I Bought Another X1/9

- Thread starter aarpcard

- Start date

Dan Sarandrea (Phila)

Waitin' On Parts...

Since I had to wait 10 minutes between coats, I decided to pass the time by refinishing the air filter container. Nearly all the paint was gone and it was very rusty. Finished pic:

View attachment 13883

I'll post the final results when I finish the passenger's seat and I'll keep you guys updated on the quality/longevity of the finish. The driver's seat came out about as well as I was expecting it to, which is far from perfect, but a huge improvement from where it was.

Yep that's a 468.36% improvement, exactly!!!

It's good that you are doing all five major pieces (steering wheel, seats, door cards) at once, everything will match nicely rather than having several shades of red, which would have caught they eye and screamed "repair". One uniform color helps it all to blend together.

Just curious about the feel/texture after the filler and dye---does it seem to make the material harder or less soft to the touch?

Yep that's a 468.36% improvement, exactly!!!Lots of effort but the results are pretty darned good!

It's good that you are doing all five major pieces (steering wheel, seats, door cards) at once, everything will match nicely rather than having several shades of red, which would have caught they eye and screamed "repair". One uniform color helps it all to blend together.

Just curious about the feel/texture after the filler and dye---does it seem to make the material harder or less soft to the touch?

It's definitely made it feel a bit harder texture wise. My guess would be that it will soften up a bit after it's fully cured and I apply the leather conditioner.

Finished the other seat. Definitely came out even better due to the leather being in generally better shape than the drivers seat.

I waited for the dye to cure and then applied copius amounts of leather conditioner. That softened the leather a bit and brought more of a sheen out on the finish. I waited two more days and applied another coat of leather conditioner. I'm probably going to do at least one more application. The leather softens considerably with each application and then gets harder again over time as the conditioner penetrates into the pores.

Passenger's seat after one application of conditioner.

Full interior shot. All other surfaces have 2 applications of conditioner.

I've also started repairing a few minor rust spots I've found. The hood had some very minor surface rust that was bubbling the paint in the places shown below. I've since neutralized, filled, primed, and painted. Letting the paint cure and will wetsand/buff tomorrow. Wasn't easy to get the filler to match the creases in the hood. I also fixed a few scratches on the engine cover and a scratch on the trunk lid.

I waited for the dye to cure and then applied copius amounts of leather conditioner. That softened the leather a bit and brought more of a sheen out on the finish. I waited two more days and applied another coat of leather conditioner. I'm probably going to do at least one more application. The leather softens considerably with each application and then gets harder again over time as the conditioner penetrates into the pores.

Passenger's seat after one application of conditioner.

Full interior shot. All other surfaces have 2 applications of conditioner.

I've also started repairing a few minor rust spots I've found. The hood had some very minor surface rust that was bubbling the paint in the places shown below. I've since neutralized, filled, primed, and painted. Letting the paint cure and will wetsand/buff tomorrow. Wasn't easy to get the filler to match the creases in the hood. I also fixed a few scratches on the engine cover and a scratch on the trunk lid.

Dan Sarandrea (Phila)

Waitin' On Parts...

Wow those seats are RED!

Night and day comparing the before/after pix. Looks great!

Does the car have a basecoat/clearcoat paint job, or single stage? I know it's a lot harder to spot-repair basecoat/clearcoat.

Night and day comparing the before/after pix. Looks great!

Does the car have a basecoat/clearcoat paint job, or single stage? I know it's a lot harder to spot-repair basecoat/clearcoat.

Did a bunch of little things today.

Most notable is I replaced the stock muffler with the Monza exhaust I recently bought from johnph. The Monza muffler was intended for the older style systems with the longer cats. So I cut off a section of the stock muffler pipe and welded it to the input flange of the Monza exhaust to extend it. The stock muffler had a hole in it and I have another stock muffler in great condition, so I didn't mind chopping it up. Welds aren't the prettiest . . . but they seem to be air tight and strong enough. I kept the flange in place so in theory you could chop the extended pipe off and use it on an older setup still.

While I was at it I finally got around to installing the stainless steel exhaust hanger brackets I bought from sawadee-khap several months ago.

Not sure why the image is hazy. I also sand blasted and painted the muffler with VHT paint.

All buttoned up:

Personally I think it adds a lot to the appearance of the rear end of the car. I always felt the stock single tail pipe was a little anemic looking for a mid-engined Italian sports car.

I tried to capture the difference in sound, but the video doesn't really do it justice. The Monza is definitely throatier and a little louder than stock. It also pops a bit occasionally when the throttle is let off. It's not considerably louder than stock which is great - I was worried it was going to be obnoxious, but it is far from it.

There is a bit of a drone at ~4500rpm under load, but it might not be a big deal with the top off. I might try replacing the cat with a resonator to see how that affects it.

Most notable is I replaced the stock muffler with the Monza exhaust I recently bought from johnph. The Monza muffler was intended for the older style systems with the longer cats. So I cut off a section of the stock muffler pipe and welded it to the input flange of the Monza exhaust to extend it. The stock muffler had a hole in it and I have another stock muffler in great condition, so I didn't mind chopping it up. Welds aren't the prettiest . . . but they seem to be air tight and strong enough. I kept the flange in place so in theory you could chop the extended pipe off and use it on an older setup still.

While I was at it I finally got around to installing the stainless steel exhaust hanger brackets I bought from sawadee-khap several months ago.

Not sure why the image is hazy. I also sand blasted and painted the muffler with VHT paint.

All buttoned up:

Personally I think it adds a lot to the appearance of the rear end of the car. I always felt the stock single tail pipe was a little anemic looking for a mid-engined Italian sports car.

I tried to capture the difference in sound, but the video doesn't really do it justice. The Monza is definitely throatier and a little louder than stock. It also pops a bit occasionally when the throttle is let off. It's not considerably louder than stock which is great - I was worried it was going to be obnoxious, but it is far from it.

There is a bit of a drone at ~4500rpm under load, but it might not be a big deal with the top off. I might try replacing the cat with a resonator to see how that affects it.

lookforjoe

True Classic

Looks pretty good  Did it come with the modified rear panel, or did you have to cut yours? Or did you save the one from the parts car ?

Did it come with the modified rear panel, or did you have to cut yours? Or did you save the one from the parts car ?

Looks pretty goodDid it come with the modified rear panel, or did you have to cut yours? Or did you save the one from the parts car ?

Yep, it came with a modified rear grill - still had to massage it a bit to prevent all rubbing.

So in the process of installing the Monza muffler, I took a good look at the cat. It's on it's last legs, if not already completely shot (holes in the honeycomb).

I have another good cat I could bolt on as a replacement, however I've decided I want to try and first replace the cat thats currently on the car with a resonator to see how that affects the exhaust note.

My thoughts are to cut the flanges off of the bad cat and weld them to a resonator so that way I can swap between configurations easily.

The problem I'm running into is that the exhaust piping on the X is all 1.5" diameter, while the smallest inlet/outlet pipe diameters I can find for resonators is 2". Does anyone have any suggestions for a resonator with 1.5" inlet/outlet pipes?

What would be the downsides of stepping up from 1.5" to 2" and then back down to 1.5" on either side of the resonator (assuming there is room to do so)?

I have another good cat I could bolt on as a replacement, however I've decided I want to try and first replace the cat thats currently on the car with a resonator to see how that affects the exhaust note.

My thoughts are to cut the flanges off of the bad cat and weld them to a resonator so that way I can swap between configurations easily.

The problem I'm running into is that the exhaust piping on the X is all 1.5" diameter, while the smallest inlet/outlet pipe diameters I can find for resonators is 2". Does anyone have any suggestions for a resonator with 1.5" inlet/outlet pipes?

What would be the downsides of stepping up from 1.5" to 2" and then back down to 1.5" on either side of the resonator (assuming there is room to do so)?

I'm posting this from my not-so-smart phone since I'm currently lacking a computer. Therefore there'll probably typos/rotated pictures/who know what. Bear with me haha!

I decided it was time to address the electrics. Everything was functional, but in typical X1/9 fashion, the power windows were slow, the wipers were really slow (barely moved unless they were lubricated with rain), and the headlights were weak. Don't even think about having them all on at the same time.

So I designed a secondary relay/fuse box to put in the frunk which incorporated all of the popular X1/9 electrics mods plus a few more I haven't seen. Specifically:

-Brown Wire Mod

-Wiper relay mod

-Power Window Relay mod

-Low Beam headlight relay mod

-Ignition switch starter solenoid relay mod

-Tail lights/running lights/marker lights relay mod

. . .All contained in one small box in the frunk.

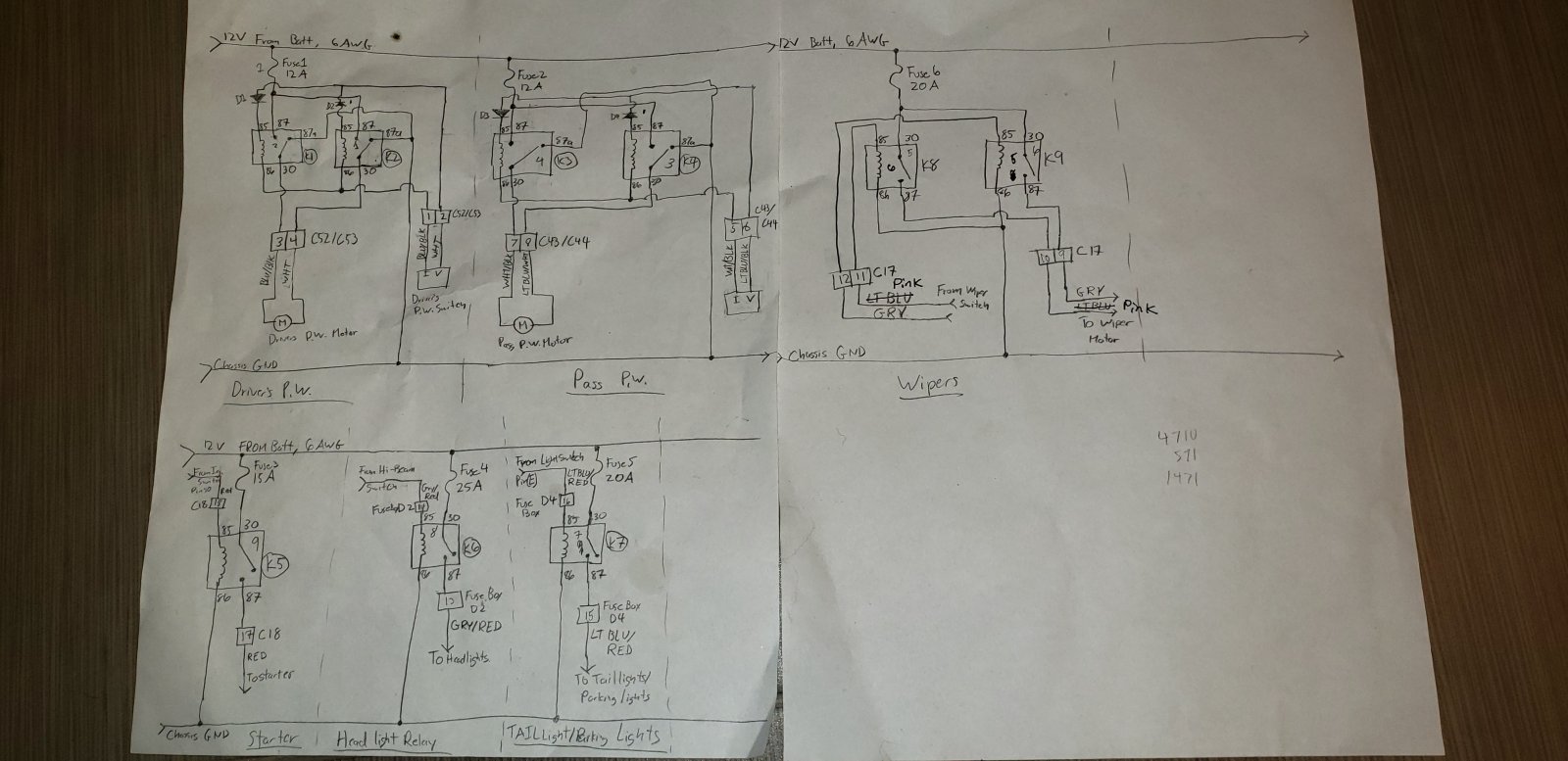

Here are the schematics. Some of the notation will probably only make sense to me because I used my own wire numbers.

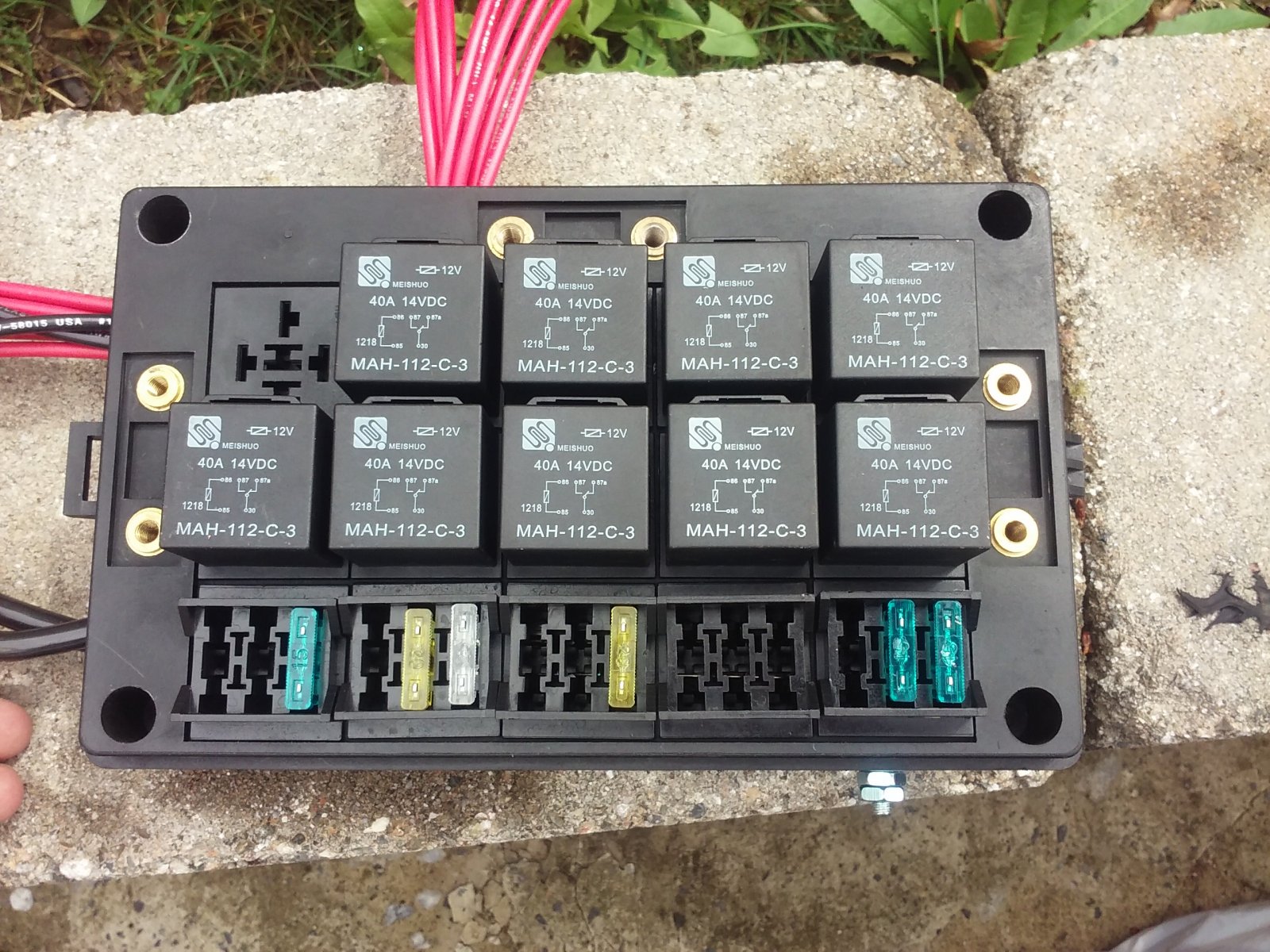

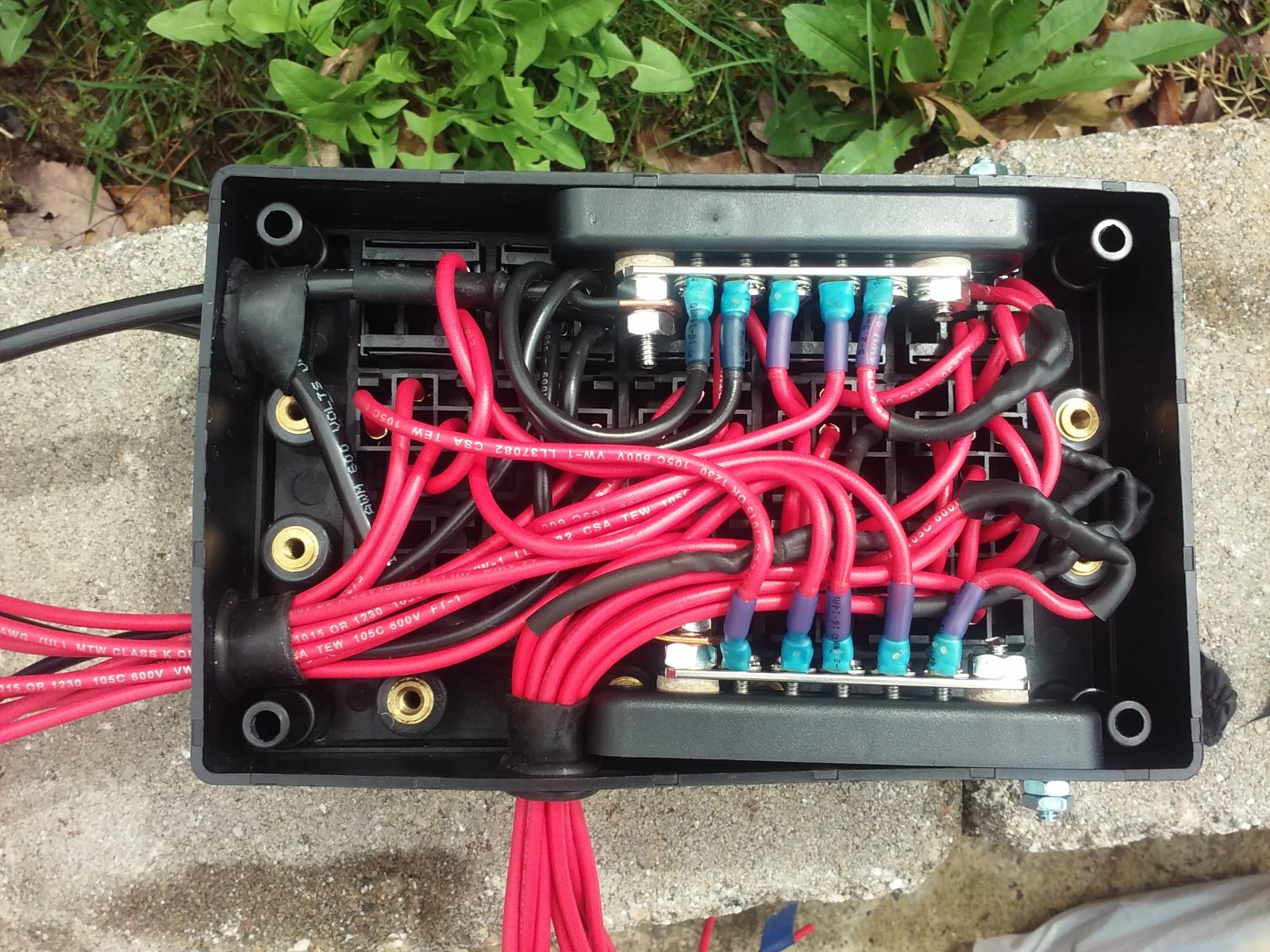

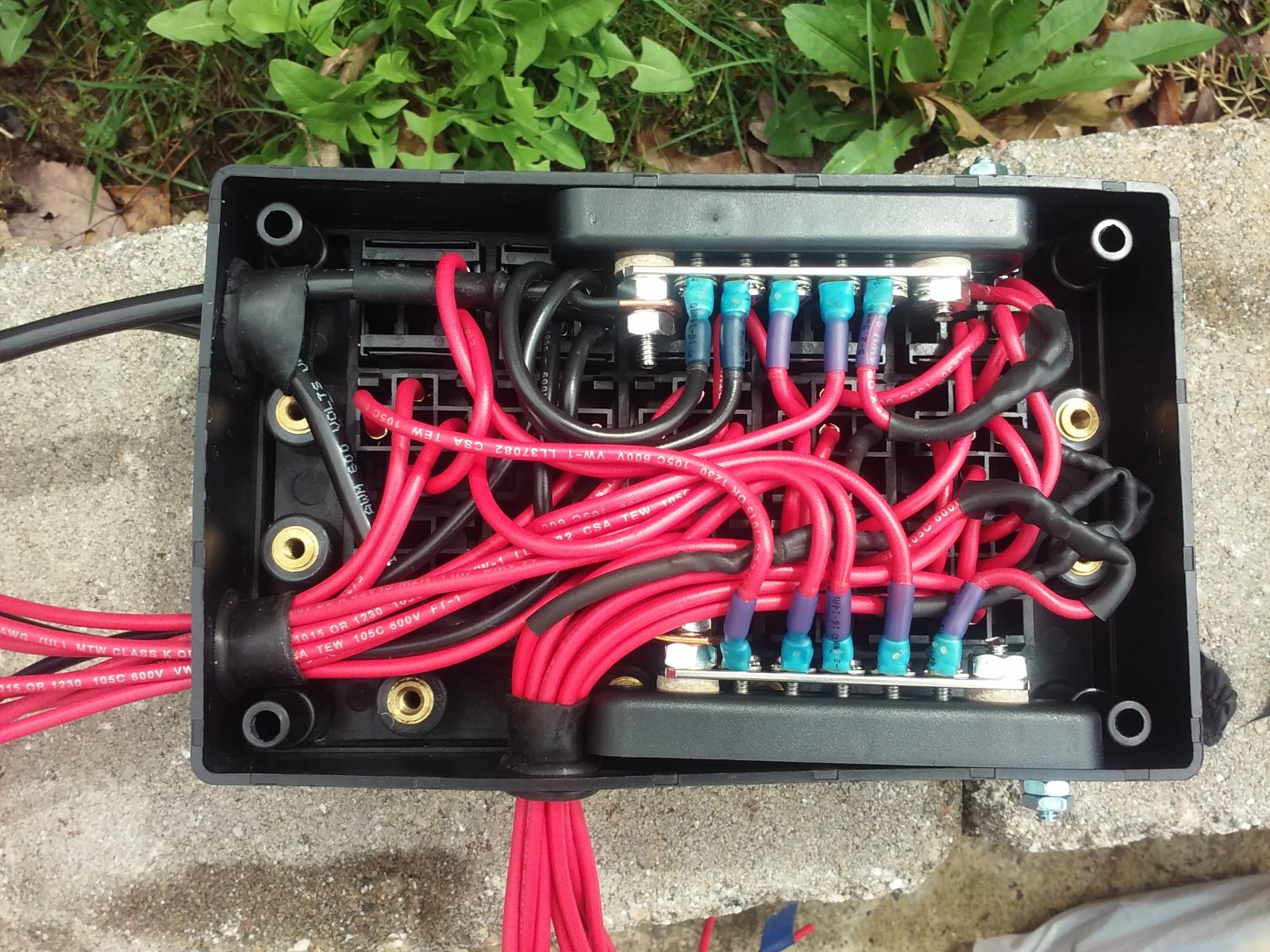

Pictures of the box prior to being installed in the car:

Pictures of the box after being installed in the frunk.

I still need to work on the cable management a bit and figure out a way to secure the box to the floor of the frunk.

I also designed it to be completely reversible. I didn't cut any original wiring. I purchased/reused connectors that mated to the original wiring harnesses at all of the hookup points. If you wanted to, you could easily remove the mod and return it to stock. Not sure why you would want to though.

Picture of the wiper motor harness hookup:

I didn't grab pictures of the other hookup points, but you get the idea.

And the best part...

Everything running at once. Lights are bright! Wipers are fast! Power windows are snappy! All at the same time!

I decided it was time to address the electrics. Everything was functional, but in typical X1/9 fashion, the power windows were slow, the wipers were really slow (barely moved unless they were lubricated with rain), and the headlights were weak. Don't even think about having them all on at the same time.

So I designed a secondary relay/fuse box to put in the frunk which incorporated all of the popular X1/9 electrics mods plus a few more I haven't seen. Specifically:

-Brown Wire Mod

-Wiper relay mod

-Power Window Relay mod

-Low Beam headlight relay mod

-Ignition switch starter solenoid relay mod

-Tail lights/running lights/marker lights relay mod

. . .All contained in one small box in the frunk.

Here are the schematics. Some of the notation will probably only make sense to me because I used my own wire numbers.

Pictures of the box prior to being installed in the car:

Pictures of the box after being installed in the frunk.

I still need to work on the cable management a bit and figure out a way to secure the box to the floor of the frunk.

I also designed it to be completely reversible. I didn't cut any original wiring. I purchased/reused connectors that mated to the original wiring harnesses at all of the hookup points. If you wanted to, you could easily remove the mod and return it to stock. Not sure why you would want to though.

Picture of the wiper motor harness hookup:

I didn't grab pictures of the other hookup points, but you get the idea.

And the best part...

Everything running at once. Lights are bright! Wipers are fast! Power windows are snappy! All at the same time!

Last edited:

Dan Sarandrea (Phila)

Waitin' On Parts...

That's pretty spiffy!

DanielForest

True Classic

You are giving yourself a lot of trouble. Almost everybody switched to "test pipes". So, no resonator at all. I don't know if test pipes with the compatible flanges are still available, but you could just cut the flanges and fit a straight pipe with clamps over the old one or weld it.So in the process of installing the Monza muffler, I took a good look at the cat. It's on it's last legs, if not already completely shot (holes in the honeycomb).

I have another good cat I could bolt on as a replacement, however I've decided I want to try and first replace the cat thats currently on the car with a resonator to see how that affects the exhaust note.

My thoughts are to cut the flanges off of the bad cat and weld them to a resonator so that way I can swap between configurations easily.

The problem I'm running into is that the exhaust piping on the X is all 1.5" diameter, while the smallest inlet/outlet pipe diameters I can find for resonators is 2". Does anyone have any suggestions for a resonator with 1.5" inlet/outlet pipes?

What would be the downsides of stepping up from 1.5" to 2" and then back down to 1.5" on either side of the resonator (assuming there is room to do so)?

You may have to be a little "creative" since there is not much space on the right side. Maybe just cutting a little more and fitting a bend on that side before the straight one for the middle.

Looks great.

I would suggest ditching the monster wiper fluid container, getting one half the size and putting your fabulous box of worms alongside the battery.

Nice job, very impressive results. You would think it was a modern car...

Thanks, hmm that's not a bad idea. I'd like to figure out a way without having to still holes for bolts anywhere, but I'm starting to think that might be unavoidable.

tonyism7

Daily Driver

I'm posting this from my not-so-smart phone since I'm currently lacking a computer. Therefore there'll probably typos/rotated pictures/who know what. Bear with me haha!

I decided it was time to address the electrics. Everything was functional, but in typical X1/9 fashion, the power windows were slow, the wipers were really slow (barely moved unless they were lubricated with rain), and the headlights were weak. Don't even think about having them all on at the same time.

So I designed a secondary relay/fuse box to put in the frunk which incorporated all of the popular X1/9 electrics mods plus a few more I haven't seen. Specifically:

-Brown Wire Mod

-Wiper relay mod

-Power Window Relay mod

-Low Beam headlight relay mod

-Ignition switch starter solenoid relay mod

-Tail lights/running lights/marker lights relay mod

. . .All contained in one small box in the frunk.

Here are the schematics. Some of the notation will probably only make sense to me because I used my own wide numbers.

View attachment 21528

Pictures of the box prior to being installed in the car:

View attachment 21529

View attachment 21530

Pictures of the box after being installed in the frunk.

View attachment 21531

View attachment 21532

I still need to work on the cable management a bit and figure out a way to secure the box to the floor of the frunk.

I also designed it to be completely reversible. I didn't cut any original wiring. I purchased/reused connectors that mated to the original wiring harnesses at all of the hookup points. If you wanted to, you could easily remove the mod and return it to stock. Not sure why you would want to though.

Picture of the wiper motor harness hookup:

View attachment 21534

I didn't grab pictures of the other hookup points, but you get the idea.

And the best part...

Everything running at once. Lights are bright! Wipers are fast! Power windows are snappy! All at the same time!

Who makes that box? Makes the install look really professional

Rod Midkiff

True Classic

I am also digging that Box. If that is an off the shelf item please share.!!

Who makes that box? Makes the install look really professional

I am also digging that Box. If that is an off the shelf item please share.!!

I found it on ebay: https://www.ebay.com/itm/US-Automot...808586?hash=item23b2929e4a:g:i4MAAOSwNClcf4cS

I was really impressed with the quality for the price. It definitely made the project much easier.

lookforjoe

True Classic

Everything running at once. Lights are bright! Wipers are fast! Power windows are snappy! All at the same time!

Are the attachments to the bus bars eyelet terminals? Or spade ring terminals?

Are the attachments to the bus bars eyelet terminals? Or spade ring terminals?

They are all eyelet crimp style terminals, but after crimping I soldered them for good measure.

lookforjoe

True Classic

They are all eyelet crimp style terminals, but after crimping I soldered them for good measure.

The bus bars were included? No pics of that in any auctions I looked at.

Last edited: