I'm in the (slow) process of rebuilding a couple of X engines. I found the same as

@Agnelli with the crank and rods; not a lot of wear or damage so I'll just polish the journals and install new bearings. My cylinders also have a fair amount of glaze. But I'm keeping these engines stock and simple so I'll reuse the original pistons (also in great shape) and just hone the cylinders with new rings. Based on the current measurements they will likely be on the maximum end of the tolerance specs, but I'm opting not to replace the pistons so no need to rebore the cylinders. It would be different if I wanted to up the compression with different pistons, then I would definitely go oversized to get a perfect bore. We'll see how it goes.

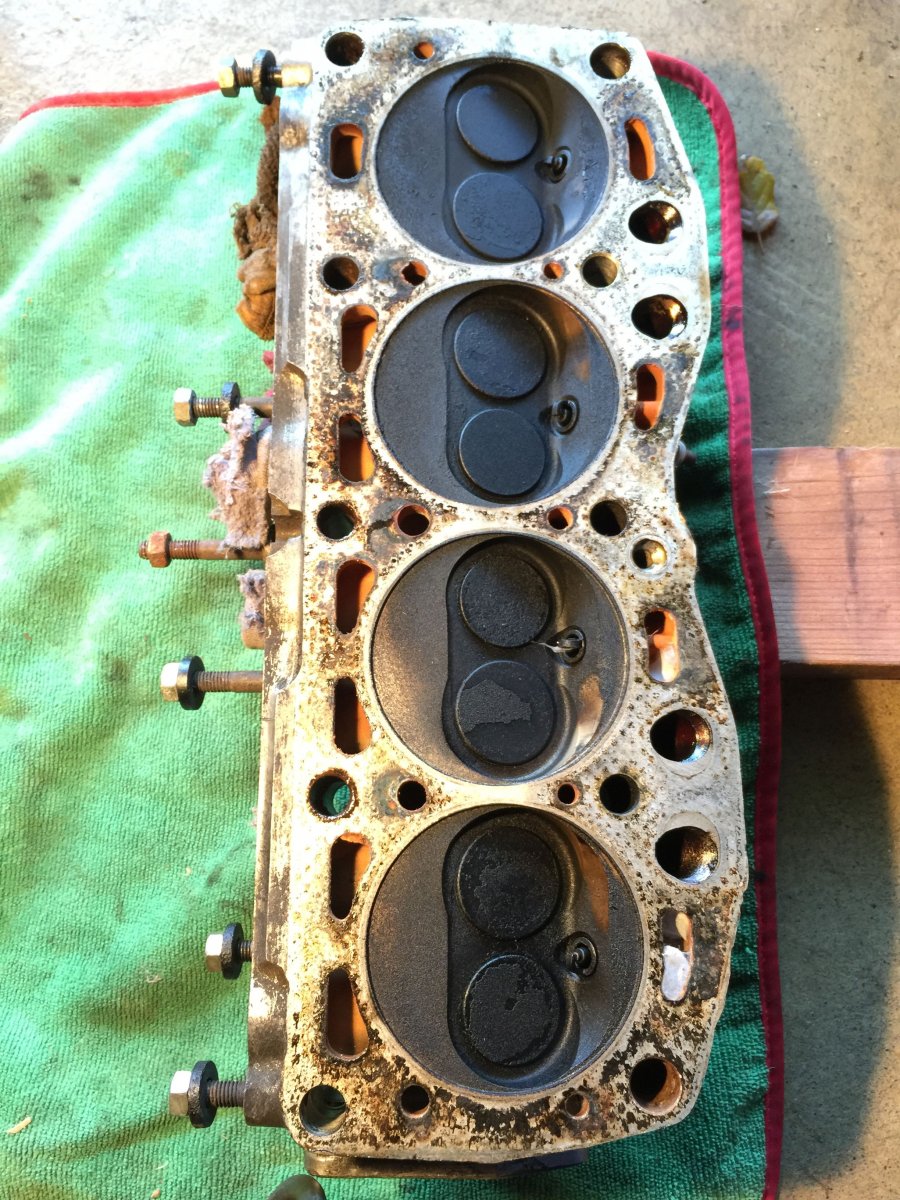

Regarding the head, big valves, porting, etc, I'm with Paul and Cliff and follow Steve C's experience (just my opinion). According to how I interpret his write up, the biggest single advantage is gained from opening up the throat diameter a bit at the inlet valve seats. He says even a small increase there, with the stock size valves, will offer very close to that of bigger valves. And he says there isn't much to be gained from porting aside from the bowl area (which gets very involved due to the guides and overall location). So if you are going to install bigger valves and new guides then I think it is worth doing some porting (

IF the person doing it knows what they are doing and has a flowbench). In other words at that point you should commit to doing everything for a maximum benefit. Otherwise it doesn't seem to be worth the risk of screwing things up (like

@CnC79X19 said, messing with velocity) or only going part way with it. For me that means the alternative is to keep the head relatively stock (as far as the valves, ports, etc are concerned), and only do some basic clean up (these castings are very crude from the factory). Part of that clean up would include matching the bowl throats with the seats - they tend to be way off on these heads - in the same manner that I would match the ports between the manifold and head. In the process of doing that I also opened up the intake throats a little as Steve describes. But you need to watch the size/width of the contact area between the valves and seat; as you open the throat you also decrease that surface, so there is a limit to how much you can do. A reface of the seats and valves after words will also help (mine appeared to have been done recently so I only lapped them).

Again, this is only my opinion and for my particular application. Everyone's goals are different. But if the engine will be in a regular street driven only car like mine, and you want good driving manners and reliability, then maintaining lots of low end torque is the way to go.