A/C rebuild.

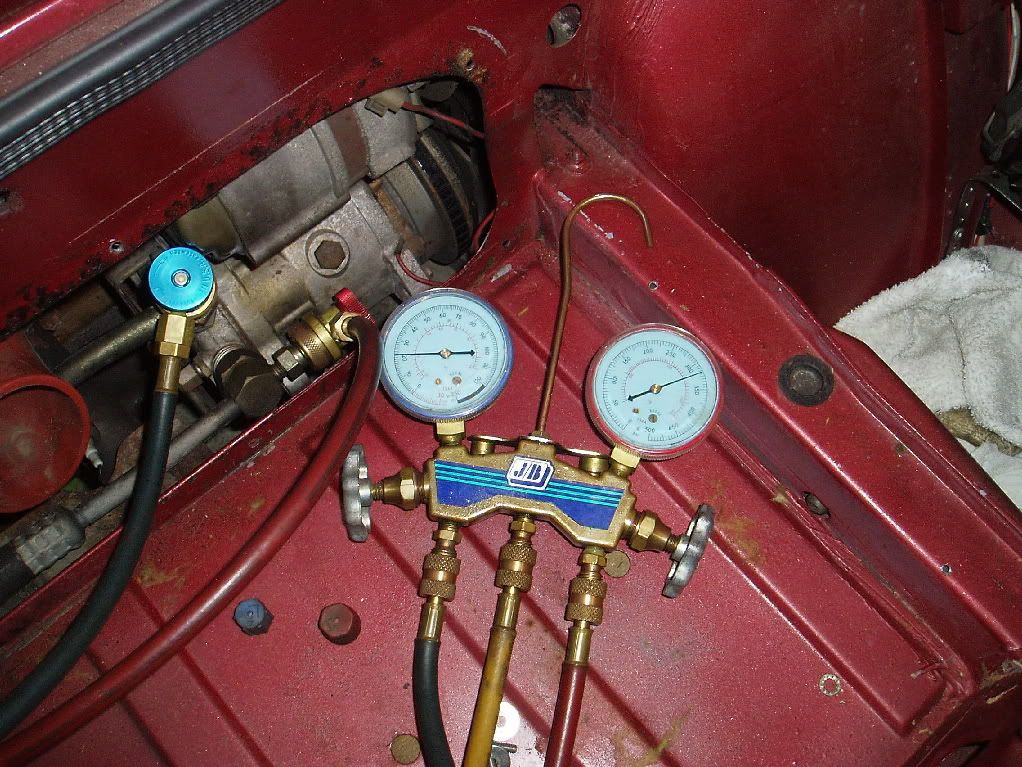

Duane, I have redone the A/C on my 87 and it works very well. I installed a new shaft seal on the compressor about 2 weeks ago. The compressor is a Sanden 508, the counter guy at Car Quest looke up the compressor then what vehicle used the compressor, then looked up a jeep that used it and found the seal part number. The seal was $29 had it the next day. Some guy say they purchased a tool to install it, but If you are careful you don't need it to change the seal and remove the old one.

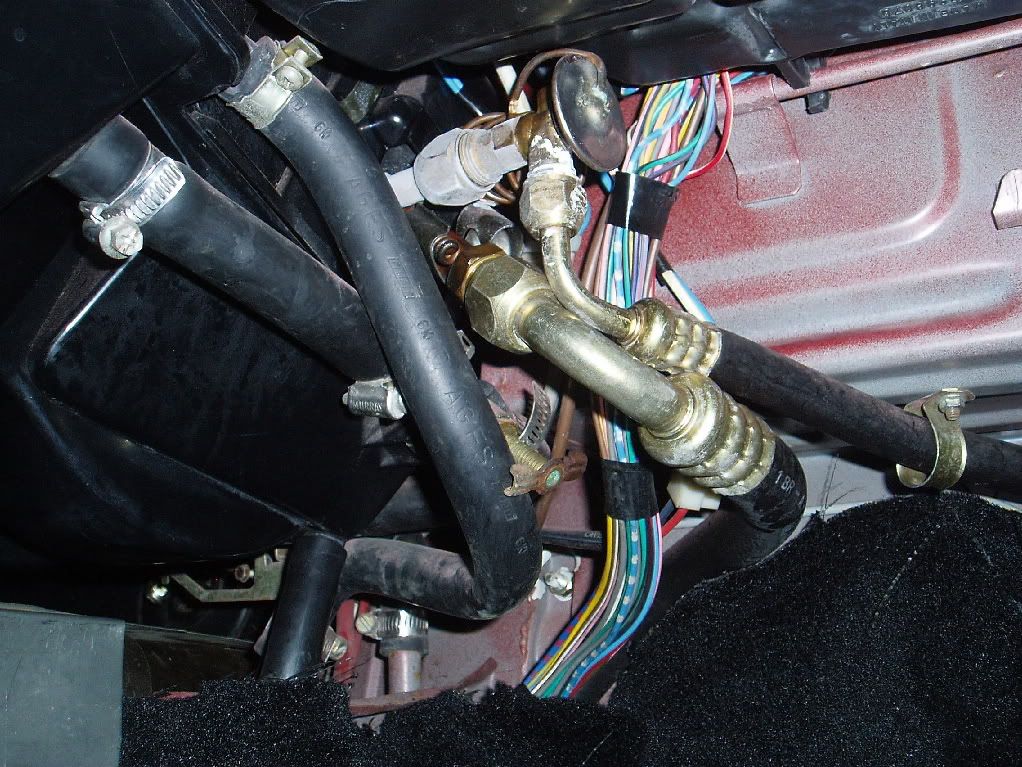

I have also changed all the O ring seals I purchased a bag from Car quest and installed the 134a ports. When I did the recharge I first used a can of Dura Cool and topped up with 134a. When you install the 134a ports the Alternator end cover will have to modified, see pictures.

If the Expansion valve is working correctly and the system is charged you should get frost like this. The X does not use a frost sensor, but a heat and pressure sensor on the high side line at the air dryer to assume there is frost on the evaporator. Goofy yes, but if you need more explaination just ask.

Make sure these switches are secured against the pressure lines in the front trunk.

This where I bought the expansion valve for $20.

Nostalgic Air Parts [info*nostalgicairparts.com]

This how the ports connect, low side about 20 PSI, High side just over 300PSI.

Seals from Car Quest, no vehicle type just a bag of them, more than enough to do an X.

If you have any Questions just email me.

TonyK.

Grimsby Ontario Canada.