Dr.Jeff

True Classic

A while back I mentioned trying a different product to repair some large cracks in one of my dashes. Here's a little more on it. If you hate my long winded narratives, then skip to the last paragraph for a summary.

This dash had the typical two cracks, one on either side of the defrost vent - top center of the dash. Plus some smaller 'dents' and cracks where the brittle vinyl had been damaged. [I did not take any pics of it before or during the early stages.]

First I ground back the raised hardened vinyl that had curled up on either side of the cracks. I used a 3M "Roloc" disc to make quick easy work of that:

I had to grind back almost 2 inches on either side to get to where it was pretty flat again. Along with the vinyl came a lot of rotted foam padding that was under the covering. So by the time I had things ground back I was left with two huge "V" shaped valleys deep into the dash, from the front to the back, all the way down to the metal subframe.

The "filler" I was experimenting with is a flexible acrylic 'plastic' product you've seen advertised on TV. Think of that goofy guy making a boat out of chicken wire, called "FlexSeal".

They market it as a waterproofing or leak sealant and they call it "rubber", but in reality it is none of those things. A couple years ago at a trade show I was given some boxes of sample products from that company. There was aerosol cans of waterproofing, tubes of "glue", and other things I don't remember. At that time they did not offer the "paste" you now see advertised. I tried some of the spray 'sealant' on a couple applications and it is total garbage, doesn't work at all to seal anything. I also tried the 'glue' on a couple of things and it doesn't work at all to glue anything. So I had very little expectations for it and the rest of the samples just sat in a box.

But as I thought about filling these huge cracks in the dash, I did not want to go the common path of body filler. For one thing these voids were much too large to fill with bondo, and for another it dries hard and won't allow any movement of the dash pad without cracking again. Someone makes a filler product for repairing dashes but I'd need a dozen of those tiny cans and they aren't cheap. So I decided to try the FlexSeal I had left over. I think what they now call "Flex Paste" would be best.

This stuff reminds me of a cross between acrylic calking (like DAP) and "Plasti Dip" (the stuff you can cover your car with and peel off later). It is viscous, creamy and sticky but not overly messy. It cleans up pretty easily before it cures - which takes a day or two. And best of all you can use it directly from the container as is - no catalyst to mix and no short window before it goes off. Honestly I just globbed it heavily into the huge cracks, filling them as much as possible with the first application. You can spread it sort of like you would body filler. And it can be lightly sanded after it cures, but only to a limit; if you get too aggressive with the sanding it will ball up and roll up and possibly even tear. But with fine grit paper and a fairly light touch it will shape and even feather pretty well. Therefore it is best to get it as close to your desired shape when you apply it, reducing the amount of sanding needed later. And it doesn't shrink like many products. I applied a couple of additional coats to get the surface flat. Here are some pics as I was sanding and building up the filler:

Looking down from above. The yellow lines represent where the major cracks were....

Closer view; still needs sanding and another layer here...

Eventually I filled all the way across the voids to their ends. As mentioned there were other spots that also got filled. Plus I decided to eliminate the headlight switch hole ('79 dash) and cigarette lighter hole by filling them the same way.

After filling everything I wanted to experiment more, this time with using a type of "truck bed liner" to cover the dash. I'd seen this done online a long time ago, then someone here (I think it was 'Look for Joe') mentioned it again. This dash was in rather poor shape all around. And it was the Fiat "turd" brown I hate. So I either needed to completely recover the surface in vinyl, or cover it with something heavy enough to hide all of its sins. There are a variety of truck bed liner (TBL) products with all sorts of different features and finishes. I chose to use a very inexpensive, commonly available product that comes in aerosol cans. This is a one-part (non-catalyzed) product that tends to go on thinner than most TBLs, has less "texture" than most others, and drys to a matte black finish. With the spray can type it is just like painting and no messy clean up.

I found that the more layers you build up the heavier the texture becomes. Actually I put on too much for my preference. Next time I would only put on one light coat. Then if needed I would use paint over that to provide better color coverage. But here is what it looks like with the TBL on:

Here's where the headlight switch was:

And where the lighter was (bad pic):

For a smoother surface it can be sanded or scuffed with a 3M "Scotch Brite" pad or fine paper. I will be recovering the dash, which was the plan all along, but it turned out much better looking than I expected. I may even keep part of it like this and only cover part.

Summary:

Use a Roloc disc to grind back the raised edges of the cracks until they are level with the rest of the dash.

Glob in a bunch of Flex Paste to fill the void and spread it as smooth and flat as possible.

Let it cure then sand any high spots with a fine grit paper.

Fill and sand again as needed to get the desired repair.

Paint one light coat of a spray can 'truck bed liner' product.

Lightly scuff the surface with a Scotch Pad to get the preferred finish/texture.

If desired you can paint over that to get the color you want.

This dash had the typical two cracks, one on either side of the defrost vent - top center of the dash. Plus some smaller 'dents' and cracks where the brittle vinyl had been damaged. [I did not take any pics of it before or during the early stages.]

First I ground back the raised hardened vinyl that had curled up on either side of the cracks. I used a 3M "Roloc" disc to make quick easy work of that:

I had to grind back almost 2 inches on either side to get to where it was pretty flat again. Along with the vinyl came a lot of rotted foam padding that was under the covering. So by the time I had things ground back I was left with two huge "V" shaped valleys deep into the dash, from the front to the back, all the way down to the metal subframe.

The "filler" I was experimenting with is a flexible acrylic 'plastic' product you've seen advertised on TV. Think of that goofy guy making a boat out of chicken wire, called "FlexSeal".

They market it as a waterproofing or leak sealant and they call it "rubber", but in reality it is none of those things. A couple years ago at a trade show I was given some boxes of sample products from that company. There was aerosol cans of waterproofing, tubes of "glue", and other things I don't remember. At that time they did not offer the "paste" you now see advertised. I tried some of the spray 'sealant' on a couple applications and it is total garbage, doesn't work at all to seal anything. I also tried the 'glue' on a couple of things and it doesn't work at all to glue anything. So I had very little expectations for it and the rest of the samples just sat in a box.

But as I thought about filling these huge cracks in the dash, I did not want to go the common path of body filler. For one thing these voids were much too large to fill with bondo, and for another it dries hard and won't allow any movement of the dash pad without cracking again. Someone makes a filler product for repairing dashes but I'd need a dozen of those tiny cans and they aren't cheap. So I decided to try the FlexSeal I had left over. I think what they now call "Flex Paste" would be best.

This stuff reminds me of a cross between acrylic calking (like DAP) and "Plasti Dip" (the stuff you can cover your car with and peel off later). It is viscous, creamy and sticky but not overly messy. It cleans up pretty easily before it cures - which takes a day or two. And best of all you can use it directly from the container as is - no catalyst to mix and no short window before it goes off. Honestly I just globbed it heavily into the huge cracks, filling them as much as possible with the first application. You can spread it sort of like you would body filler. And it can be lightly sanded after it cures, but only to a limit; if you get too aggressive with the sanding it will ball up and roll up and possibly even tear. But with fine grit paper and a fairly light touch it will shape and even feather pretty well. Therefore it is best to get it as close to your desired shape when you apply it, reducing the amount of sanding needed later. And it doesn't shrink like many products. I applied a couple of additional coats to get the surface flat. Here are some pics as I was sanding and building up the filler:

Looking down from above. The yellow lines represent where the major cracks were....

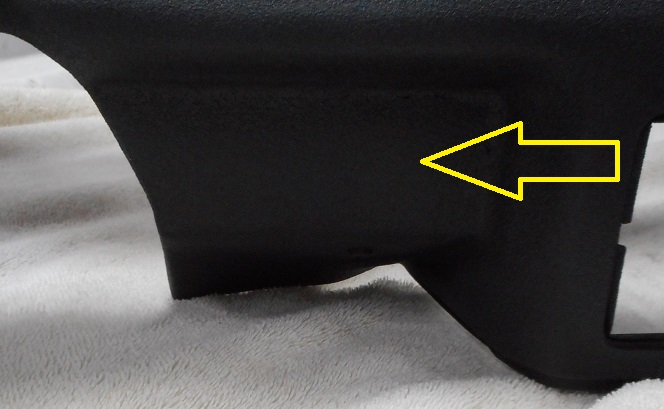

Closer view; still needs sanding and another layer here...

Eventually I filled all the way across the voids to their ends. As mentioned there were other spots that also got filled. Plus I decided to eliminate the headlight switch hole ('79 dash) and cigarette lighter hole by filling them the same way.

After filling everything I wanted to experiment more, this time with using a type of "truck bed liner" to cover the dash. I'd seen this done online a long time ago, then someone here (I think it was 'Look for Joe') mentioned it again. This dash was in rather poor shape all around. And it was the Fiat "turd" brown I hate. So I either needed to completely recover the surface in vinyl, or cover it with something heavy enough to hide all of its sins. There are a variety of truck bed liner (TBL) products with all sorts of different features and finishes. I chose to use a very inexpensive, commonly available product that comes in aerosol cans. This is a one-part (non-catalyzed) product that tends to go on thinner than most TBLs, has less "texture" than most others, and drys to a matte black finish. With the spray can type it is just like painting and no messy clean up.

I found that the more layers you build up the heavier the texture becomes. Actually I put on too much for my preference. Next time I would only put on one light coat. Then if needed I would use paint over that to provide better color coverage. But here is what it looks like with the TBL on:

Here's where the headlight switch was:

And where the lighter was (bad pic):

For a smoother surface it can be sanded or scuffed with a 3M "Scotch Brite" pad or fine paper. I will be recovering the dash, which was the plan all along, but it turned out much better looking than I expected. I may even keep part of it like this and only cover part.

Summary:

Use a Roloc disc to grind back the raised edges of the cracks until they are level with the rest of the dash.

Glob in a bunch of Flex Paste to fill the void and spread it as smooth and flat as possible.

Let it cure then sand any high spots with a fine grit paper.

Fill and sand again as needed to get the desired repair.

Paint one light coat of a spray can 'truck bed liner' product.

Lightly scuff the surface with a Scotch Pad to get the preferred finish/texture.

If desired you can paint over that to get the color you want.

Last edited: