You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Distributor options

- Thread starter chumley

- Start date

Ics19

belle macchine!

Take the cap off and take a clear large picture or two and post them. There should be an advance mechanism of two plates plus springs, and the actuating rod from the vacuum advance connects to this. In the marelli 178 distributor used on the last carbed cars, the vacuum advance option is replaced by a dummy plastic plate to hold the mechanism in place so only the centrifugal part works - yours may need something similar, as an unconnected vacuum unit may not hold the mechanism firm and cause unnecessary fluctuations - assuming there is a spring based centrifugal mechanism, it may need respringing to get the advance you need. The assembly will be either above or below your pickup, which I assume is the magnetic reluctor type - this should have a gap of 0.25 - 0.4 mm if it's the same spec as the 124 pack.

Last edited:

Ics19

belle macchine!

You'll likely find one of the holes for the pickup fixing screws is slightly elongated such that it allows the pickup position to be adjusted - the amount of travel is very small as you're only looking at a 0 - 0.5mm range at most:can't see any way of setting gap

However, as yours fits upside down it, it looks a PITA to get access to in situ - the alternative way and perhaps better, is to "feel" each lobe register at the pickup when the shaft is rotated by hand - it should just be noticeable when they snap into place. But this isn't your issue, as it clearly runs, I was just suggesting you check it while it's out.

Are you saying there's ***no** timing advance when you increase the revs, i.e. the mark just stays static at 5/10 degrees? The centrifugal advance mechanism should be doing something, just maybe not enough with the vacuum unit non-functional.

The split plastic rod angle of intersection to the curved vacuum unit plate looks very similar to the plastic blanking piece used on the 178 distributors - you'll likely find an overpriced repro part that might fit on your favourite auction site should you decide not to use the vacuum unit...

Last edited:

Thanks for the reply I'm sorry didn't check advance with strobe while I had it running but I set it to 10 btdc and it had no guts and didn't want to rev very high but turned dizzy while running and found an improvement but after shutting off and trying to start found way to much advance and wouldn't start . Could I JB weld advance and try some weaker springs perhaps. So do you think I have right dizzy I was thinking I got one that needed a crank sensor

Ics19

belle macchine!

You seem to have a number of variables going on: new cam, new carbs, new distributor? Did it run fine with the old distributor? You could try to fix the rod, but if there's minimal movement, say 1mm or so, then I doubt it's going to upset things too much at the moment - you seem to have bigger problems afoot. No, you don't need a sensor as there's nothing that needs one - the distributor is just a pickup and the ignition module is a glorified amplifier and switch that is (hopefully) controlling the dwell period and optimising the current for the coil. You may need some different springs, but it should idle as is to start with, assuming all other things are ok, i.e. cam & carbs. I would check the advance at say 2k then 3k, and take it from there, if it appears to have a similar curve to the old distributor then you need to look else where.

dllubin

Don

Thanks for the reply I'm sorry didn't check advance with strobe while I had it running but I set it to 10 btdc and it had no guts and didn't want to rev very high but turned dizzy while running and found an improvement but after shutting off and trying to start found way to much advance and wouldn't start . Could I JB weld advance and try some weaker springs perhaps. So do you think I have right dizzy I was thinking I got one that needed a crank sensor

Weaker springs will bring on the advance sooner. On distributors where the two weights are mechanically tied together you can try it with just one spring to bring the advance on sooner. There is also the total centrifugal advance that needs to be controlled. I actually used JB Weld to install a stop that limits the amount of centrifugal advance. Works fine.

Does your distributor specify what the sensor output is supposed to be connected to? I would assume that it was intended to go to an electronic ignition module that generates a spark when it gets a signal from the sensor. I don't quite understand your comment about it needing a crank sensor since your distributor is essentially a crank sensor.

If you have a timing light that can measure advance at speed, I would check the advance in the 3,000 to 3,500 rpm range in addition to that at idle. For best performance, it should be in the 30 to 35 degree range for most cars.

Ics19

belle macchine!

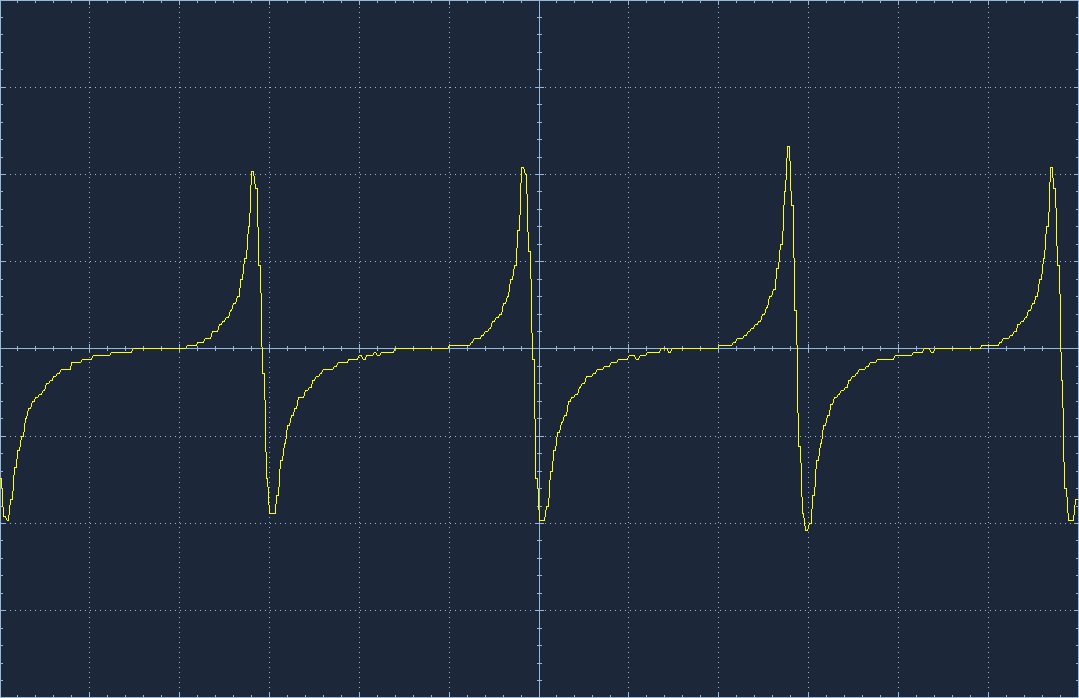

This looks very much like a 124 coil pack reluctor style pickup, so the output voltage will increase with rpm and appears as:

I think you're looking at high single digit volts peak-peak at idle, to 20-30v+ at higher rpms. The change in the rising edge effects the dwell (charge) period that the module controls, whereas the sharp fall cuts the primary current which in turn induces the secondary spark. Whether all modules are cracked up to handling such signals across the 4 cylinder rpm range is another matter.

I think you're looking at high single digit volts peak-peak at idle, to 20-30v+ at higher rpms. The change in the rising edge effects the dwell (charge) period that the module controls, whereas the sharp fall cuts the primary current which in turn induces the secondary spark. Whether all modules are cracked up to handling such signals across the 4 cylinder rpm range is another matter.

Ics19

belle macchine!

Yes, that's true, but those sparks are potentially being compromised with restricted dwell time, so not as strong as they could be, as they have to fit into a shorter finite time period. If the module was designed to provide the best (potentially longer) dwell at lower effective top rpm (as required by mere 4 cylinder engines), then that would be optimal. At the other end of the rpm spectrum, an idling 4 cylinder is only half the sparks of an 8 and it seems not all modules are equal when it comes to handling this, particularly on startup. IIRC Ferrari used two coil packs on some on their 308s using a dual trigger distributor to, in effect, implement twin 4 cylinder sparking for the best performance. I don't think this is the issue the OP has here thoughFour cylinder cars use half as many sparks per revolution as a V8 so even a high rpm 4 should not overtaxed most modules

dllubin

Don

If dwell time becomes a limiting factor, it is probably best not to use a Kettering style ignition and go with a capacitive discharge unit instead since it's timing is not limited by the coil LRC. Some CD units can actually provide multiple discharges per cycle.Yes, that's true, but those sparks are potentially being compromised with restricted dwell time, so not as strong as they could be, as they have to fit into a shorter finite time period. If the module was designed to provide the best (potentially longer) dwell at lower effective top rpm (as required by mere 4 cylinder engines), then that would be optimal. At the other end of the rpm spectrum, an idling 4 cylinder is only half the sparks of an 8 and it seems not all modules are equal when it comes to handling this, particularly on startup. IIRC Ferrari used two coil packs on some on their 308s using a dual trigger distributor to, in effect, implement twin 4 cylinder sparking for the best performance. I don't think this is the issue the OP has here though

Just to let you know how I got on I replaced dizzy with points one I had and all is well with new cam it now revs past 7k easily so for now I'll leave it till I get some springs and try again at least I know that it was that and everything thing else is ok . Once again thanks for everyone's help great forum

dllubin

Don

Glad you got it running. There is nothing wrong with a points distributor other than having to replace or adjust the points every once in a while. I'm using the stock 74 Ducelier distributor with a few mods (vacuum advance removed, centrifugal advance recurved) and no problems with the tach needle buried.Just to let you know how I got on I replaced dizzy with points one I had and all is well with new cam it now revs past 7k easily so for now I'll leave it till I get some springs and try again at least I know that it was that and everything thing else is ok . Once again thanks for everyone's help great forum