Dr.Jeff

True Classic

Today I got back to rebuilding the suspension parts and tried installing new rubber bushings into the front main arms (pics to follow). The new bushes are from a aftermarket manufacturer (Delphi) and feel noticeably firmer rubber than the stock Fiat ones. Therefore that may have something to do with my difficulty installing them. Hopefully that also makes them work a bit better once installed.

Oddly I've never had to replace these specific bushes on a X before. Done it many times on other makes of vehicles with no problems. But these were a real chore. The first attempt was how I usually do it, by placing the arm and bush in a large bench vice and squeezing them together. Even with trying all the tips and tricks I know they would not go in. So I looked on Xweb and found a couple of related threads:

Apparently I'm not the only one having difficulty installing these bushings.

The second attempt was with a gear puller/installer type tool; one with multiple arms and a threaded driver. And the suspension arm secured in a bench vice. That allowed me to keep both hands free from holding parts, so I could help guide the bush in with more tools. But I still could not get them installed. The size and shape of the outer "lips" are very overkill and keep things from going past the edge of the arm opening.

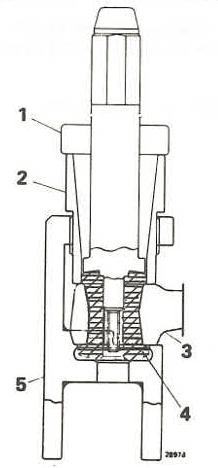

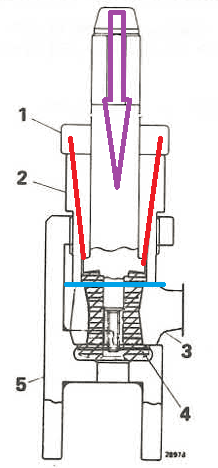

At that point I decided to make a installation tool patterned after the Fiat factory tool (#A74225), as seen in the factory workshop manual....

The concept is simple. It has a tapered sleeve or "funnel" (#2, red lines) that squeezes the rubber bush (#4) as it is pushed down into the arm (#3), by a plunger (purple arrow). A fixture (#5) holds the funnel against the arm (at the blue line) while the bushing is pushed down:

I decided this likely will get used only once so I made a tapered sleeve from a piece of scrap plastic (nylon) rod:

And simply placed it on top of the arm while pressing down on the bush with a hydraulic press. But the tapered sleeve would not stay against the arm with the high loads of the 'squeezed' rubber as it passed through.

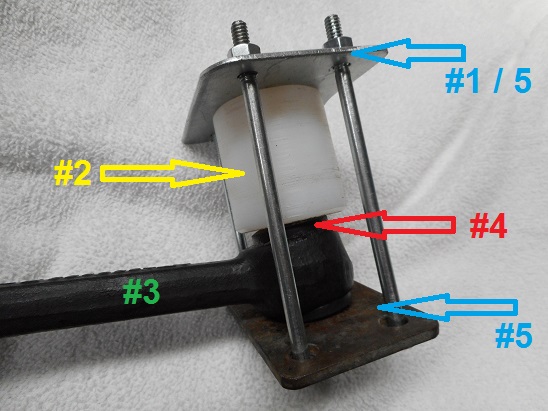

So I made a little bracket assembly to hold the tapered sleeve and arm together [the numbers correspond to the ones in the illustration above]. Note - the following pics were taken after the new bush (#4) was installed, and things reassembled for illustration purposes. Therefore it is not quite correct here:

With this extra hardware in place a driver of some sort was needed to press the bush straight down without deforming it (using the hydraulic press). I just used a bolt with a heavy washer:

With some lube the rubber bushing slid into the suspension arm rather easily:

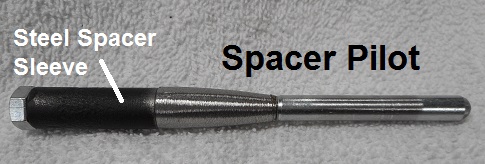

To install the metal spacer sleeve into the new rubber bush I made a simple pilot driver tool. Basically a long bolt with a tapered "bullet nose" piece on it to force the sleeve into the rubber hole (also using the press):

Metal spacer sleeve installed:

Completed installation with mounting bolt in place:

Although it took me half a day to fab these things up and finally get the bushings installed, I had already spent that long with failed prior attempts. So I guess it was worth the effort. Honestly I don't see how they can be done without such a tool of some type. I recall a comment somewhere on the forum saying "you just shove the end in and squeeze it into the arm". I highly doubt that happened. However if the bushings I have are indeed firmer, then they might be more difficult than others? Sheesh, a whole day spent on nothing but this little task. No wonder my Fiat projects take sooo much longer than my others.

Oddly I've never had to replace these specific bushes on a X before. Done it many times on other makes of vehicles with no problems. But these were a real chore. The first attempt was how I usually do it, by placing the arm and bush in a large bench vice and squeezing them together. Even with trying all the tips and tricks I know they would not go in. So I looked on Xweb and found a couple of related threads:

Front suspension bushing install

Is there any trick or special tool required to remove and install the hourglass-shaped suspension bushing for the front control arm (not the radius arm)? Getting the old one out isn't too hard because I don't worry about damaging it, but I'm not at all sure how to get the new one in.

xwebforums.com

Front Control Arm Bushing Replacement

I’m rebuilding the front suspension, my driver side front control arm ball joint is in great shape, but the bushing was gone. I’ve removed the old bushing and metal sleeve, but cannot wrap my mind around how to install the new one! I see in the manual there’s special tools for installing the...

xwebforums.com

The second attempt was with a gear puller/installer type tool; one with multiple arms and a threaded driver. And the suspension arm secured in a bench vice. That allowed me to keep both hands free from holding parts, so I could help guide the bush in with more tools. But I still could not get them installed. The size and shape of the outer "lips" are very overkill and keep things from going past the edge of the arm opening.

At that point I decided to make a installation tool patterned after the Fiat factory tool (#A74225), as seen in the factory workshop manual....

The concept is simple. It has a tapered sleeve or "funnel" (#2, red lines) that squeezes the rubber bush (#4) as it is pushed down into the arm (#3), by a plunger (purple arrow). A fixture (#5) holds the funnel against the arm (at the blue line) while the bushing is pushed down:

I decided this likely will get used only once so I made a tapered sleeve from a piece of scrap plastic (nylon) rod:

And simply placed it on top of the arm while pressing down on the bush with a hydraulic press. But the tapered sleeve would not stay against the arm with the high loads of the 'squeezed' rubber as it passed through.

So I made a little bracket assembly to hold the tapered sleeve and arm together [the numbers correspond to the ones in the illustration above]. Note - the following pics were taken after the new bush (#4) was installed, and things reassembled for illustration purposes. Therefore it is not quite correct here:

With this extra hardware in place a driver of some sort was needed to press the bush straight down without deforming it (using the hydraulic press). I just used a bolt with a heavy washer:

With some lube the rubber bushing slid into the suspension arm rather easily:

To install the metal spacer sleeve into the new rubber bush I made a simple pilot driver tool. Basically a long bolt with a tapered "bullet nose" piece on it to force the sleeve into the rubber hole (also using the press):

Metal spacer sleeve installed:

Completed installation with mounting bolt in place:

Although it took me half a day to fab these things up and finally get the bushings installed, I had already spent that long with failed prior attempts. So I guess it was worth the effort. Honestly I don't see how they can be done without such a tool of some type. I recall a comment somewhere on the forum saying "you just shove the end in and squeeze it into the arm". I highly doubt that happened. However if the bushings I have are indeed firmer, then they might be more difficult than others? Sheesh, a whole day spent on nothing but this little task. No wonder my Fiat projects take sooo much longer than my others.

Last edited: