You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

my Project X track car update

- Thread starter GregS

- Start date

Dr.Jeff

True Classic

And I certainly wasn't implying that you were, just being funny in general. It is a very old expression, but perhaps more of regional thing? Means the same as a lot of other sayings that also make no sense; it's the bomb, it's off the hook, it's off the chain, it's sweet, it's gnarly, and many more.Wasn't implying that

Mike Schofield

True Classic

I’m actually gonna start using that phrase more often now! Lol

Not sure how the millennials will think though! bahahaha!!!

Not sure how the millennials will think though! bahahaha!!!

GregS

ProjectX

Update. Over the last couple of months I have fitted a torsen type LSD to my 5 speed box, I still have no clue who it was made by, also a torque rod to the bottom engine mount and polyurethane bushes to the dog-bone torque rod.

So far I have only driven it a bit on the road to bed in new brake pads and to give the diff some miles before hitting the track with it. First impressions, there is definitely more vibration from the torque rods, as expected, and I can hear a bit of gear or bearing noise, but the real test will be later in the year when I get a chance to run on a track.

I will add links to the torque rod fit and diff if anyone wants more info rather than re-post.

from post #30, https://xwebforums.com/forum/index.php?threads/torque-with-lsd-in-x1-9-5-speed.38515/page-2 post #31 torque rod, https://xwebforums.com/forum/index.php?threads/random-transmission-failures.38210/page-2

So far I have only driven it a bit on the road to bed in new brake pads and to give the diff some miles before hitting the track with it. First impressions, there is definitely more vibration from the torque rods, as expected, and I can hear a bit of gear or bearing noise, but the real test will be later in the year when I get a chance to run on a track.

I will add links to the torque rod fit and diff if anyone wants more info rather than re-post.

from post #30, https://xwebforums.com/forum/index.php?threads/torque-with-lsd-in-x1-9-5-speed.38515/page-2 post #31 torque rod, https://xwebforums.com/forum/index.php?threads/random-transmission-failures.38210/page-2

Last edited:

kmead

Old enough to know better

Update. Over the last couple of months I have fitted a torsen type LSD to my 5 speed box, I still have no clue who it was made by, also a torque rod to the bottom engine mount and polyurethane bushes to the dog-bone torque rod.

So far I have only driven it a bit on the road to bed in new brake pads and to give the diff some miles before hitting the track with it. First impressions, there is definitely more vibration from the torque rods, as expected, and I can hear a bit of gear or bearing noise, but the real test will be later in the year when I get a chance to run on a track.

I will add links to the torque rod fit and diff if anyone wants more info rather than re-post.

from post #30, https://xwebforums.com/forum/index.php?threads/torque-with-lsd-in-x1-9-5-speed.38515/page-2 post #31 torque rod, https://xwebforums.com/forum/index.php?threads/random-transmission-failures.38210/page-2

Now about that string...

darwoodious

Darin Nelson

GregS

ProjectX

Haha, you weren't supposed to notice that. A safety measure in case the left hand wiper arm fell off, the little spring clip that secures it on the shaft wasn't holding properly.

lookforjoe

True Classic

Update. Over the last couple of months I have fitted a torsen type LSD to my 5 speed box, I still have no clue who it was made by, also a torque rod to the bottom engine mount and polyurethane bushes to the dog-bone torque rod.

So, where are the details on this? I don't need one myself, however I'd still be interested in knowing more about it & where it was purchased, etc...

GregS

ProjectX

The lsd came in a reconditioned 5 speed I bought, everything I know about it is in the lsd link above the video.So, where are the details on this? I don't need one myself, however I'd still be interested in knowing more about it & where it was purchased, etc...

lookforjoe

True Classic

The lsd came in a reconditioned 5 speed I bought, everything I know about it is in the lsd link above the video.

OK - when I clicked on the lower link it just went to the subframe/torque mount - I misread which link was which

GregS

ProjectX

This update is reposted from the "Bigger Brakes" post.

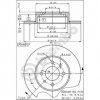

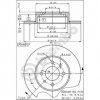

Back in December I upgraded the rear brakes on my track X. Montecarlo S2/late Fiat 132 discs, 251mm solids. Montecarlo S2 uses Fiat 124/125 caliper carrier brackets and an adaptor bracket (4447735 rear) to fit to the hub (same hub as S2 X1/9), with Fiat 125/132 rear calipers with 38mm pistons that I was already using. (X1/9 uses 34mm pistons on 227mm disc). They just fit inside the 13 inch wheels I am currently using. The Pininfarina 124 Spider uses a 257mm version of these discs, but they may or may not fit with 13 inch wheels, even 251mm won't fit with all 13". One downside of this style of disc is they weigh 4.5kg compared to 3kg for std 227mm discs, the wheel mounting face flange is 11mm thick and there is a lot of extra metal around the hub od, so I will be doing some machining on these to loose some weight. Those brackets, 4447735 are hard to find, I made copies using 10mm steel plate with a 9mm thick x 24mm od spacer/boss welded on at the caliper carrier mounting points.

I did machine the discs to loose some weight, 5mm from the wheel mounting face, 2mm on the 147 OD, and a step at the OD of the wheel mounting face to equal the 227 disc face, to go from 4.5kg to 3.7kg.

With standard front brakes and 251mm rears with 38mm pistons the braking torque is 58% front, 42% rear. Last Sunday I had a sprint meeting at The Bend West circuit and braking balance was good in a straight line, had a front brake lock momentarily once, but no drama. When trail braking into a corner there was a slight tendency for the back end to move a bit more than before, but not too bad.

I am undecided as yet whether to go with larger fronts or not, 239mm maybe, I have Regata calipers if I decide to.

Back in December I upgraded the rear brakes on my track X. Montecarlo S2/late Fiat 132 discs, 251mm solids. Montecarlo S2 uses Fiat 124/125 caliper carrier brackets and an adaptor bracket (4447735 rear) to fit to the hub (same hub as S2 X1/9), with Fiat 125/132 rear calipers with 38mm pistons that I was already using. (X1/9 uses 34mm pistons on 227mm disc). They just fit inside the 13 inch wheels I am currently using. The Pininfarina 124 Spider uses a 257mm version of these discs, but they may or may not fit with 13 inch wheels, even 251mm won't fit with all 13". One downside of this style of disc is they weigh 4.5kg compared to 3kg for std 227mm discs, the wheel mounting face flange is 11mm thick and there is a lot of extra metal around the hub od, so I will be doing some machining on these to loose some weight. Those brackets, 4447735 are hard to find, I made copies using 10mm steel plate with a 9mm thick x 24mm od spacer/boss welded on at the caliper carrier mounting points.

I did machine the discs to loose some weight, 5mm from the wheel mounting face, 2mm on the 147 OD, and a step at the OD of the wheel mounting face to equal the 227 disc face, to go from 4.5kg to 3.7kg.

With standard front brakes and 251mm rears with 38mm pistons the braking torque is 58% front, 42% rear. Last Sunday I had a sprint meeting at The Bend West circuit and braking balance was good in a straight line, had a front brake lock momentarily once, but no drama. When trail braking into a corner there was a slight tendency for the back end to move a bit more than before, but not too bad.

I am undecided as yet whether to go with larger fronts or not, 239mm maybe, I have Regata calipers if I decide to.

GregS

ProjectX

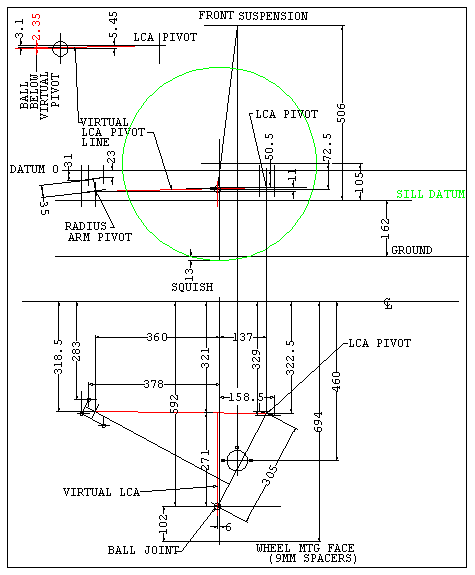

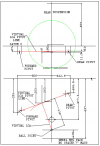

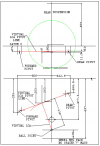

Suspension Roll Centres

After following a post on Xweb (Scuderria Ferric Oxide-Steve C) discussing Roll Centres (RC) I wondered if that may be why my cars handling on track is not as good as I would like it. After a few goes on the online VSusp calculator I eventually came up with some numbers that I think are as accurate as I can get them. It showed that with my 2.5 deg of body roll when cornering my front RC was moving from about 50mm above ground to 36mm below ground and outside the track width of the tyres. By all accounts this is not a good thing to be happening.

After much trial and error on VSusp I settled on moving the top of the struts inwards by about 20mm each side, limiting body roll to 2 deg with stiffer springs, and raising the ride height slightly to get the Virtual lower control arms to slope up towards the chassis a bit more.

I cut out the centre of the top of the front strut towers, moved them over and rewelded. I added a 4th stud to the stock top mount and rotated it 180 deg to get it as close as possible to the inside of the strut tower. I have fitted 500lb/in springs in the front and 375lb in the rear. I have set the corner weights and adjusted F and R ride heights to try and get the best compromise with roll centres with the 2 deg body roll I am hoping to achieve. I have set the rear ride height slightly lower than the front to get the rear RC at 54mm, 9mm lower than the front RC of 63mm. At 2 deg body roll the RC drops to 30mm, same as front RC at 2 deg. Camber adjusted using camber bolts at the strut to knuckle joint, -3 deg F & R.

Steve H has said that he likes to have the rear RC lower than the front RC, I’m not sure if this is mainly for autocross driving or does it apply equally to road course use? Just wondering as I have seen where Porsche 911s as standard generally have the rear RC higher than the front, I thought with their rear weight bias they may need similar balance to an X1/9, but I guess the different suspension design and spring rates etc would have a big bearing?

P.S. You can change the roll angle from 0 deg to 2 deg and see where the RC moves to in these VSusp links.

Drawings of my suspension, based on the factory X1/9 chassis drawing and my measurements.

Looking at the rear susp on the 2D Vsusp, I'm not sure how true it will be, it really needs a 3D program. Unlike the front susp the pivot points for the rear are nowhere near parallel to the car centre line. I did a CAD drawing using the factory chassis drawing as the basis, for the virtual LCA I used the length from the ball joint to 90 deg to the line between the pivots, but then turned to put it at 90 deg to the centreline to input into 2D Vsusp. Also, the factory drawing shows the F and R pivots at the same height, on my car there is a 6mm height difference.

I have also fitted new Toyo R888R 185/60 R13 to the front.

Unfortunately the track event I was intending to try it out at this weekend at The Bend has been cancelled due to covid, but there is another sprint scheduled for the end of the month, but at a tighter track.

After following a post on Xweb (Scuderria Ferric Oxide-Steve C) discussing Roll Centres (RC) I wondered if that may be why my cars handling on track is not as good as I would like it. After a few goes on the online VSusp calculator I eventually came up with some numbers that I think are as accurate as I can get them. It showed that with my 2.5 deg of body roll when cornering my front RC was moving from about 50mm above ground to 36mm below ground and outside the track width of the tyres. By all accounts this is not a good thing to be happening.

After much trial and error on VSusp I settled on moving the top of the struts inwards by about 20mm each side, limiting body roll to 2 deg with stiffer springs, and raising the ride height slightly to get the Virtual lower control arms to slope up towards the chassis a bit more.

I cut out the centre of the top of the front strut towers, moved them over and rewelded. I added a 4th stud to the stock top mount and rotated it 180 deg to get it as close as possible to the inside of the strut tower. I have fitted 500lb/in springs in the front and 375lb in the rear. I have set the corner weights and adjusted F and R ride heights to try and get the best compromise with roll centres with the 2 deg body roll I am hoping to achieve. I have set the rear ride height slightly lower than the front to get the rear RC at 54mm, 9mm lower than the front RC of 63mm. At 2 deg body roll the RC drops to 30mm, same as front RC at 2 deg. Camber adjusted using camber bolts at the strut to knuckle joint, -3 deg F & R.

Steve H has said that he likes to have the rear RC lower than the front RC, I’m not sure if this is mainly for autocross driving or does it apply equally to road course use? Just wondering as I have seen where Porsche 911s as standard generally have the rear RC higher than the front, I thought with their rear weight bias they may need similar balance to an X1/9, but I guess the different suspension design and spring rates etc would have a big bearing?

Vehicle Suspension: Front View Online Suspension Simulator

VSusp (vehicle suspension): Front View Suspension Geometry Calculator/Simulator

www.vsusp.com

P.S. You can change the roll angle from 0 deg to 2 deg and see where the RC moves to in these VSusp links.

Drawings of my suspension, based on the factory X1/9 chassis drawing and my measurements.

Looking at the rear susp on the 2D Vsusp, I'm not sure how true it will be, it really needs a 3D program. Unlike the front susp the pivot points for the rear are nowhere near parallel to the car centre line. I did a CAD drawing using the factory chassis drawing as the basis, for the virtual LCA I used the length from the ball joint to 90 deg to the line between the pivots, but then turned to put it at 90 deg to the centreline to input into 2D Vsusp. Also, the factory drawing shows the F and R pivots at the same height, on my car there is a 6mm height difference.

Vehicle Suspension: Front View Online Suspension Simulator

VSusp (vehicle suspension): Front View Suspension Geometry Calculator/Simulator

www.vsusp.com

I have also fitted new Toyo R888R 185/60 R13 to the front.

Unfortunately the track event I was intending to try it out at this weekend at The Bend has been cancelled due to covid, but there is another sprint scheduled for the end of the month, but at a tighter track.

Last edited:

Steve Hoelscher

True Classic

Greg,

Nice job relocation of the top strut mount. Curious though, why you didn't convert to a camber plate?

I haven't used Vsusp myself but have reviewed a few projects that used it for friends. I did notice a couple of issues with the rendering between the original layout and the proposed layout on a couple of those. I don't know if its the software or the operator. Could easily be either. As with any tool the results are dependent on the operator as any tool can be misused.

Your note about roll center height and migration are not terribly out of line with my study of the X chassis but its been more than a decade since I did anything with my car in that respect. So my memory of that work is not what it once was.

Fundamentally, you discovered one of the limitations of the strut chassis, body roll destroys the geometry. Thus I set my car up to limit roll as much as possible. The problem there is the diminishing returns curve. There is a range where the car works well but as you try to go stiffer in roll, the additional roll stiffness begins to compromise mechanical grip. The X has a window in the 1 to 2 degree total roll range where it works. Beyond that the geometry begins to fall apart and create issues. Below that stiffness begins to erode grip. Not that the top level racing Shifter Karts have a total roll just over 1 degree.

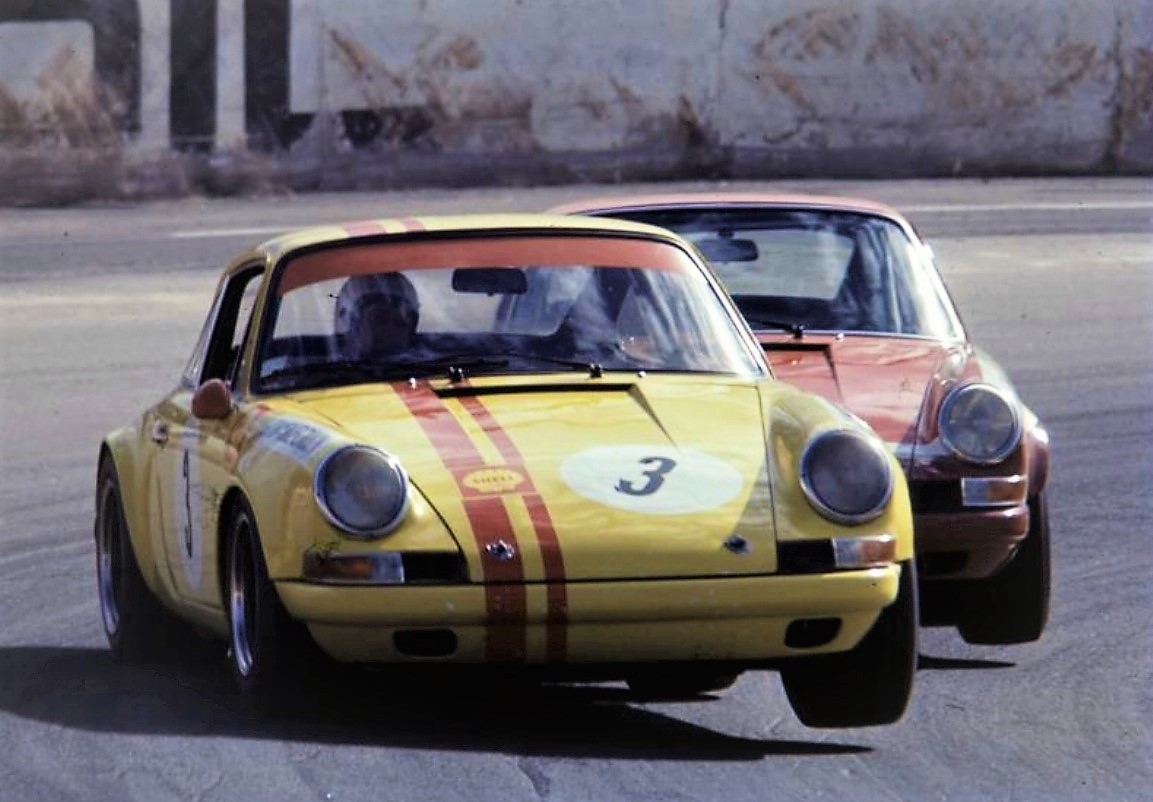

Also, curious which 911 you were referring to. There are a few generations of 911 suspension. The early trailing arm cars, when setup for competition, typically had the rear roll center below the front. Later versions, with more sophisticated suspension designs raised the rear roll center relative to the front. By then the design had advanced significantly and the rear grip issue was able to be compensated with other methods.

Note the two photos below. This is a nearly direct comparison of the effects of rear weight bias and a lower rear roll center. The rear roll moment arm forces the front end to roll beyond 100% weight transfer the chassis lifts the inside front tire. The effect is to move the front roll center to the contact patch of the outside front tire. This means that 100% of the load transfer is now shifted to the outside rear tire. This overloads that tire and reduces overall mechanical grip. The challenge is to tune the roll center heights to increase the rear mechanical grip without lifting the inside front. No small challenge. This is why I spend so much time tuning with roll center heights on rear weight bias cars. As soon as you lift the inside front the car goes loose.

Note the first is an autocross car and the 2nd are road racing cars. It really doesn't matter as the task is the same.

Then my X1/9:

On my car its the application of throttle on corner exit that shifts weight rearward and lifts the front on corner exit. This car I didn't have the luxury of easy RC adjustment to address such issues.

Nice job relocation of the top strut mount. Curious though, why you didn't convert to a camber plate?

I haven't used Vsusp myself but have reviewed a few projects that used it for friends. I did notice a couple of issues with the rendering between the original layout and the proposed layout on a couple of those. I don't know if its the software or the operator. Could easily be either. As with any tool the results are dependent on the operator as any tool can be misused.

Your note about roll center height and migration are not terribly out of line with my study of the X chassis but its been more than a decade since I did anything with my car in that respect. So my memory of that work is not what it once was.

Fundamentally, you discovered one of the limitations of the strut chassis, body roll destroys the geometry. Thus I set my car up to limit roll as much as possible. The problem there is the diminishing returns curve. There is a range where the car works well but as you try to go stiffer in roll, the additional roll stiffness begins to compromise mechanical grip. The X has a window in the 1 to 2 degree total roll range where it works. Beyond that the geometry begins to fall apart and create issues. Below that stiffness begins to erode grip. Not that the top level racing Shifter Karts have a total roll just over 1 degree.

Also, curious which 911 you were referring to. There are a few generations of 911 suspension. The early trailing arm cars, when setup for competition, typically had the rear roll center below the front. Later versions, with more sophisticated suspension designs raised the rear roll center relative to the front. By then the design had advanced significantly and the rear grip issue was able to be compensated with other methods.

Note the two photos below. This is a nearly direct comparison of the effects of rear weight bias and a lower rear roll center. The rear roll moment arm forces the front end to roll beyond 100% weight transfer the chassis lifts the inside front tire. The effect is to move the front roll center to the contact patch of the outside front tire. This means that 100% of the load transfer is now shifted to the outside rear tire. This overloads that tire and reduces overall mechanical grip. The challenge is to tune the roll center heights to increase the rear mechanical grip without lifting the inside front. No small challenge. This is why I spend so much time tuning with roll center heights on rear weight bias cars. As soon as you lift the inside front the car goes loose.

Note the first is an autocross car and the 2nd are road racing cars. It really doesn't matter as the task is the same.

Then my X1/9:

On my car its the application of throttle on corner exit that shifts weight rearward and lifts the front on corner exit. This car I didn't have the luxury of easy RC adjustment to address such issues.

GregS

ProjectX

Thanks Steve for the detailed response.

Not camber plates? I wanted to keep the rubber top mounts to minimize shock loads into the towers, (I don't always run on smooth race surfaces), plus I was going to have to add positive camber at the bottom of the strut anyway.

VSusp software? I'm not 100% convinced my results are accurate, but it's all I have. Any small error in inputs can make quite a difference, and I did notice on one occasion with a small input I made the output in VSusp wasn't consistent with previous results. Also the rear suspension Virtual LCA is not a true representation of the X suspension just so I can do it in 2D.

Which 911 model RCs? Apparently when the Turbo (930) was introduced in 1975 they raised the rear RC compared to previous 911s with a different trailing arm etc. The stock RCs for the 993 F 56mm, R 73.5mm, 996 model F 63, R 76. These are not modified for racing versions.

The 997.2 GT3 RC are F 55mm, R 30mm. So this more track focused model does have the rear RC lower than the front. All these figures are off internet forums (Rennlist or Pelican Parts) so I have no idea if they are accurate.

Love the photos of the Porsche's and your X.

Sounds like I'm going to have some fun fine tuning my setup, I was thinking I can raise or lower the rear suspension fairly easily at the track to change the rear RC without affecting any other geometry too much. I may need a spotter with a camera at the track to see what the front inside wheel is doing, and also how much body roll there is now.

Not camber plates? I wanted to keep the rubber top mounts to minimize shock loads into the towers, (I don't always run on smooth race surfaces), plus I was going to have to add positive camber at the bottom of the strut anyway.

VSusp software? I'm not 100% convinced my results are accurate, but it's all I have. Any small error in inputs can make quite a difference, and I did notice on one occasion with a small input I made the output in VSusp wasn't consistent with previous results. Also the rear suspension Virtual LCA is not a true representation of the X suspension just so I can do it in 2D.

Which 911 model RCs? Apparently when the Turbo (930) was introduced in 1975 they raised the rear RC compared to previous 911s with a different trailing arm etc. The stock RCs for the 993 F 56mm, R 73.5mm, 996 model F 63, R 76. These are not modified for racing versions.

The 997.2 GT3 RC are F 55mm, R 30mm. So this more track focused model does have the rear RC lower than the front. All these figures are off internet forums (Rennlist or Pelican Parts) so I have no idea if they are accurate.

Love the photos of the Porsche's and your X.

Sounds like I'm going to have some fun fine tuning my setup, I was thinking I can raise or lower the rear suspension fairly easily at the track to change the rear RC without affecting any other geometry too much. I may need a spotter with a camera at the track to see what the front inside wheel is doing, and also how much body roll there is now.

Last edited: