I came up with a solution to be able to drive the oil pump and prime the lubrication system.

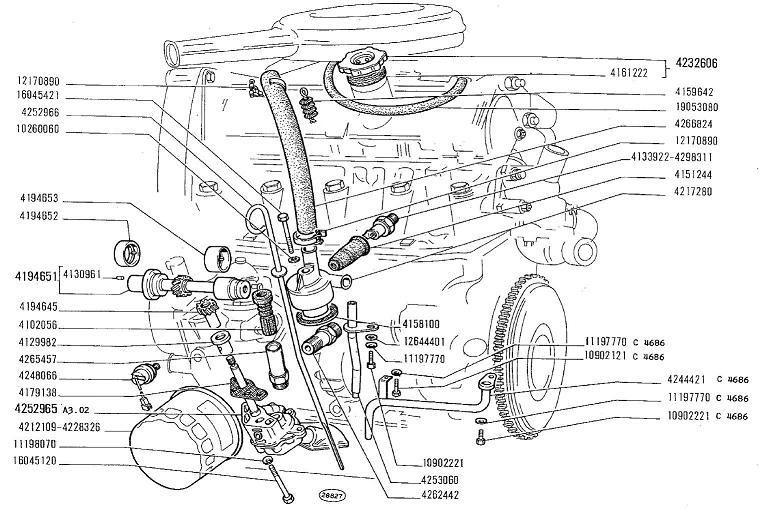

Unfortunately with the engine in the vehicle there is no room to drive the aux shaft directly (with the timing belt off). So the next approach was to drive the pump from the distributor side. But rather than pull the distributor and drive gear out and make an adapter from a old gear, I decided to approach it a little differently. By leaving the distributor in place and just removing the cap and rotor, I made a drive adapter that fits where the rotor would normally be. Effectively driving the distributor externally and therefore the oil pump. The timing belt still needs to be off the aux shaft sprocket so it can spin as well. But overall it is the easiest approach I could come up with.

To make the drive adapter for the distributor, I mimicked the way the rotor mounts onto the top of the distributor shaft. A 14 mm 6-point socket has the same ID as the rotor, and fits over the distributor shaft well. Naturally it still needs something to engage with the notch in the shaft, otherwise the socket will just spin on it. Using a spare socket I drilled a hole through its side wall and tapped it for a #10 screw (bolt). The shank of the screw is the width of the notch in the distributor shaft and engages with it to turn the shaft.

The only issue with retaining the distributor in place (while driving the oil pump) is the angle and height of it approaches the firewall. So there is not enough room to hold some type of power tool above it. This was easily overcome by using a "wobble" socket adapter (U-joint) and a cordless drill. The joint allows the drill to be held at a slight angle to clear the firewall. A hex drive bit with a 1/4" head is chucked in the drill to connect everything.

Here are some pictures to show how it all went together:

A cheap/used 14 mm socket from a swap meet will work. But in a pinch the #10 screw could be removed and the socket is still usable. With a variable speed cordless drill the shaft can be turned gently at first, then increased to full speed once the oil begins to flow. I was also able to check the oil pressure at various speeds this way.