It does appear to be half of the centering spring for the translator.

They do occasionally break ad it's always at the mount.

I just went out to the shop and snapped this pic of one.

View attachment 35896

There is no other piece in the transmission that is anything like that.

Of course somebody could have dropped something during assembly. I have seen it before and done it myself.

I assume that your shift lever now doesn't have a positive self centering action on the 3-4 shift gate. The half of the centering spring that is broken is the half that keeps the shifter from falling to the 1-2 gate.

Also, you are quite fortunate that you found that piece stuck to the drain plug. You can see it has been beat up from bouncing around inside. If it had gotten ingested between two gears you would have had an instantaneous catastrophic transmission failure.

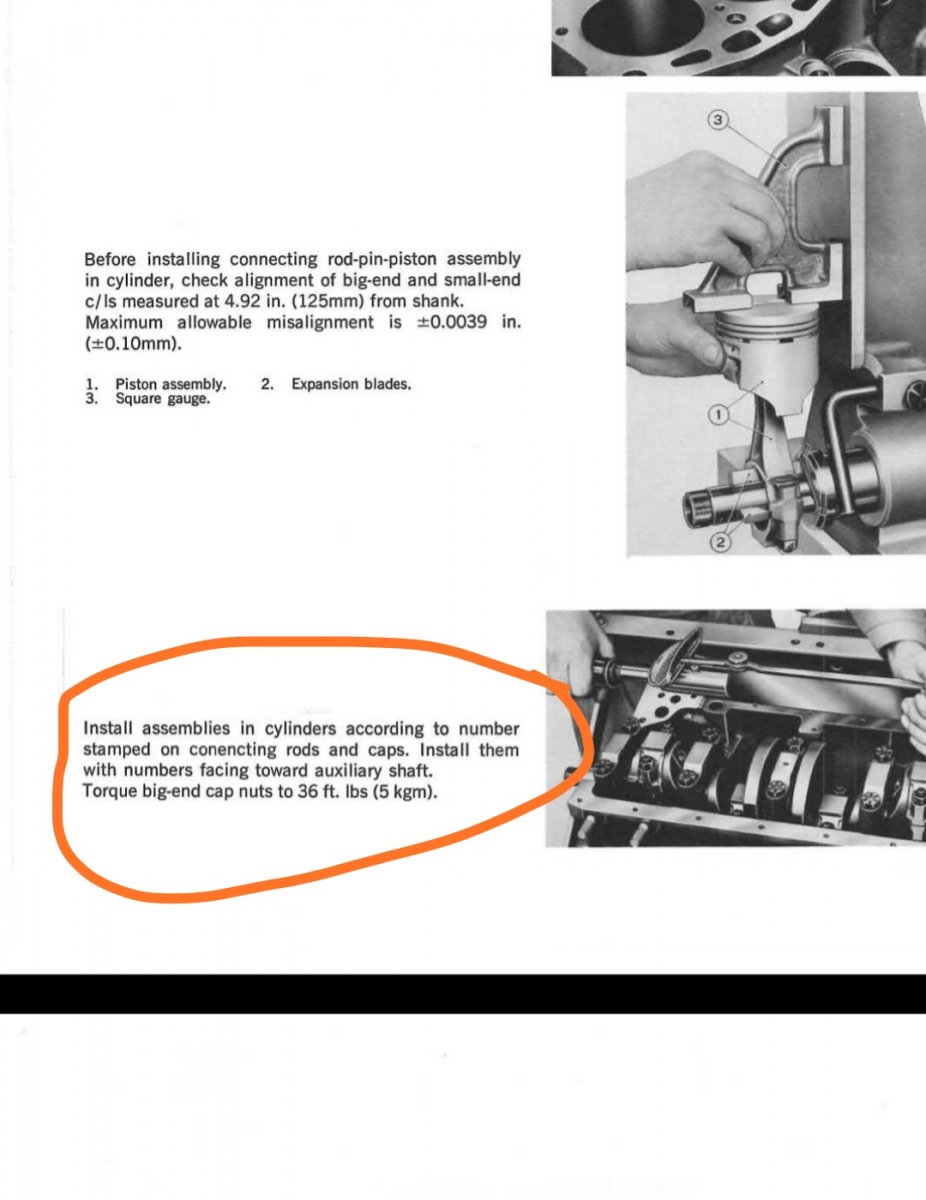

To replace it you will need to open up the transmission and swap out the translator (the assembly in the photo I posted).