Got the wiring harness tidied up before I trimmed the junction area

The decel bypass solenoid connector didn't look any better than this EGR one, so I cut that off & replaced it

Volvo used a somewhat similar connector, with better waterproofing, through the early 90's, so I replaced it with that type

Removed the EGR solenoid, valve & vacuum & exhaust tube while I was there - had to put a helicoil in one stud location

blocked off the exhaust manifold port

Made a blanking plate & added an elbow 10mm quick release for the booster line. I reinstalled the Datsun check valve, I found that the PO's tech had installed it backwards, with the grey side pointing at the intake. No wonder there were notes on the brake booster not feeling right.

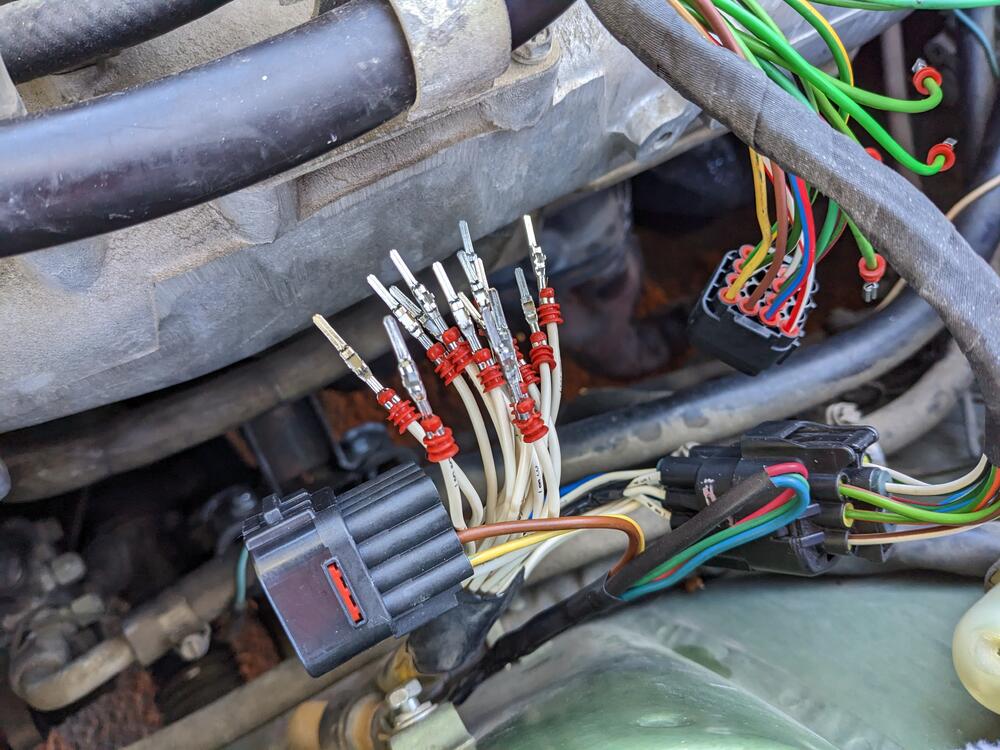

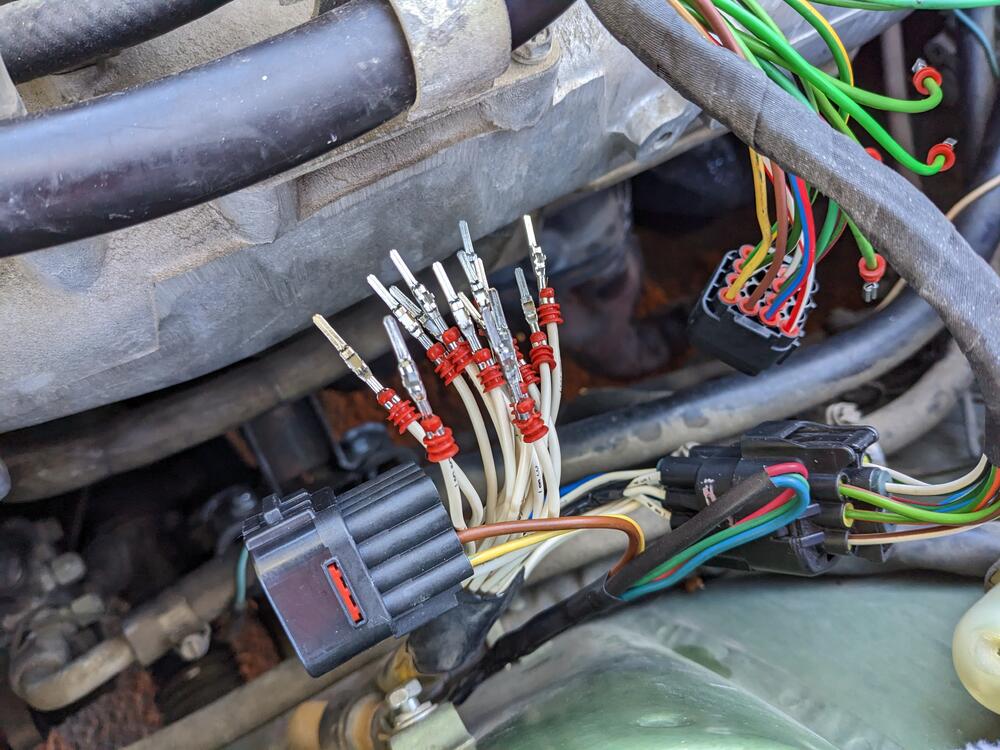

crimping all the Delphi terminals - 16way for injectors (12) Decel solenoid, Coolant gauge, and ECT

The TPS, CSV, Thermal timer, AAR are in the Sumitomo TS hybrid 090/187 housing on the right

Back together & running. Didn't resolve the cold start issue entirely. I need to add a pressure gauge & see what the pump is doing, and actually function test the CSV/timer circuit

Edit- this morning I needed to move the car to a friend's garage for the coming week while we are in Iceland. It actually started on the second try, and ran much better than previously, so perhaps the wiring and possibly reversed ECT & thermal timer connections have resolved much of it.