lookforjoe

True Classic

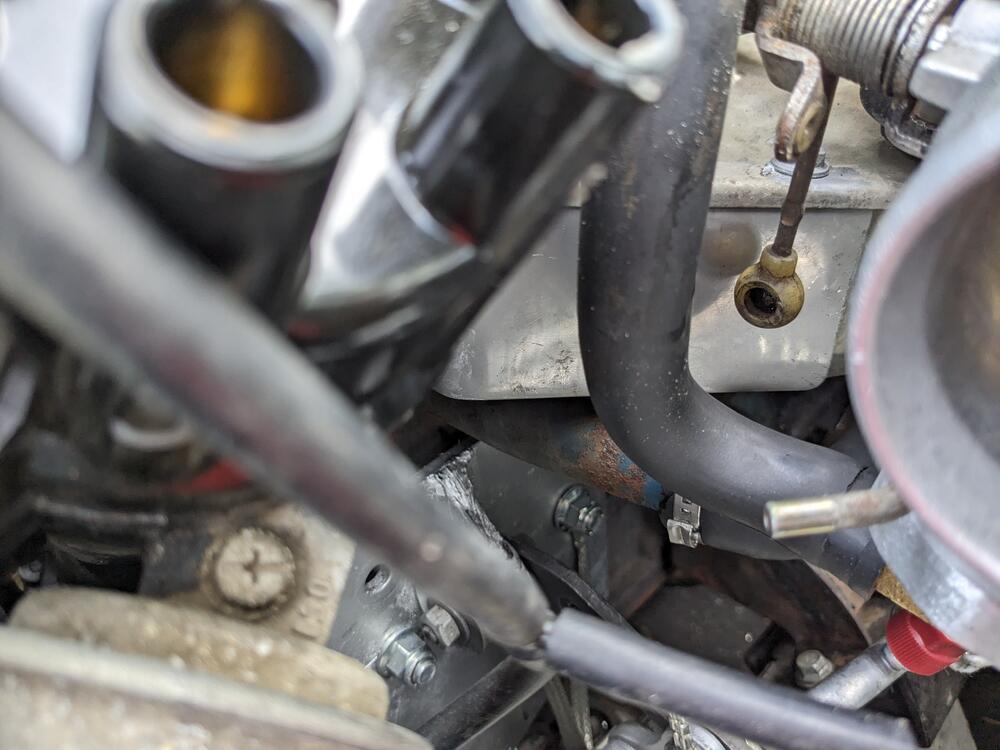

Added heat shielding for the AC lines

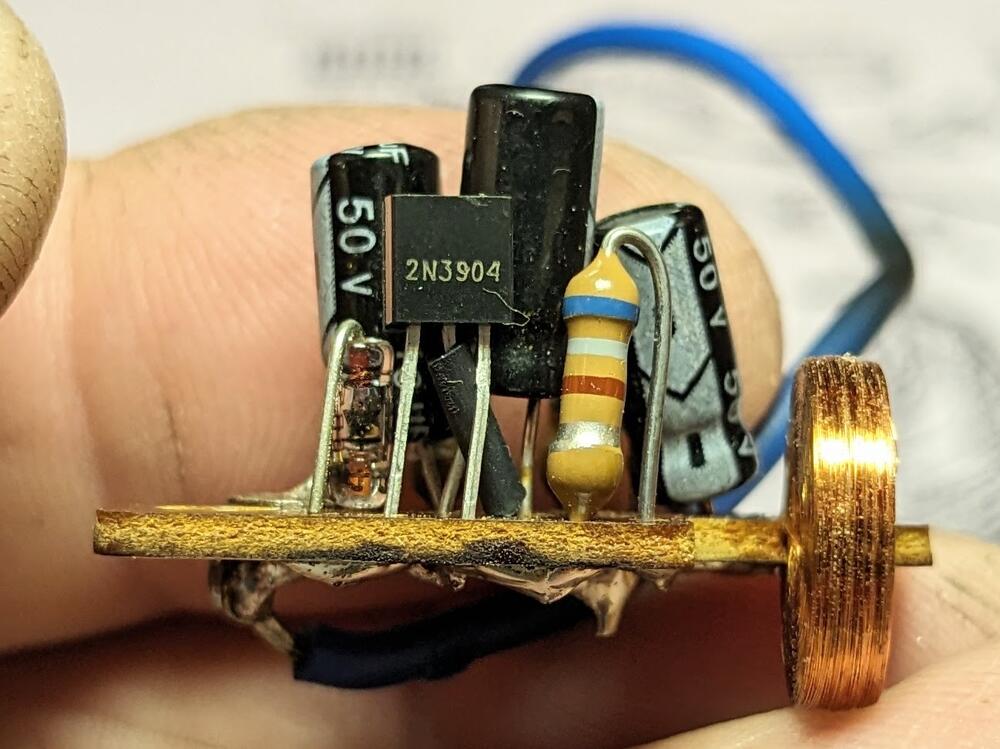

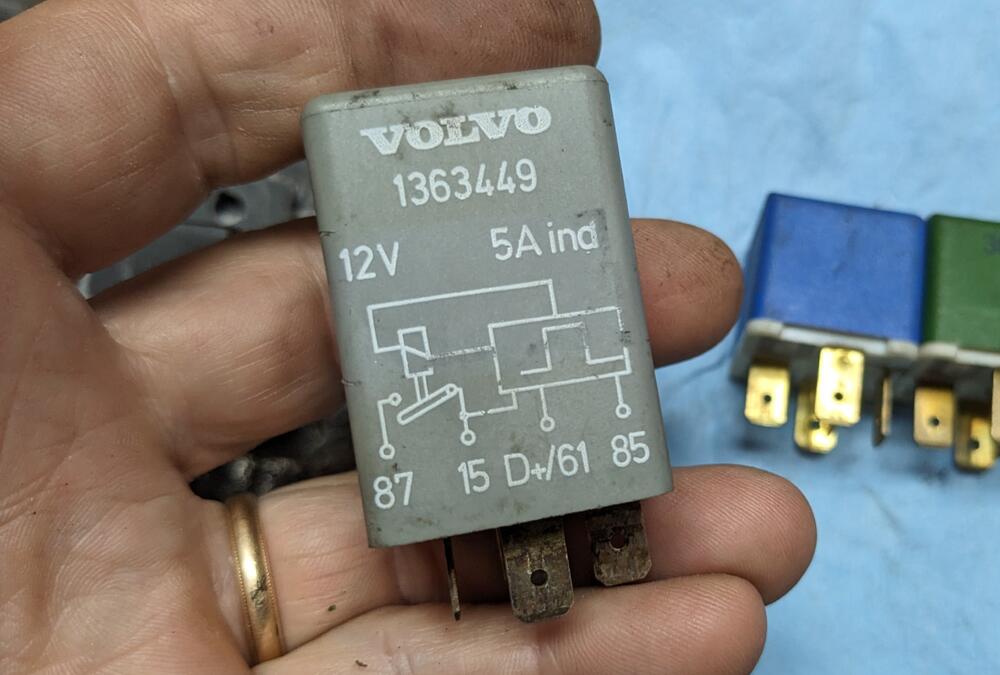

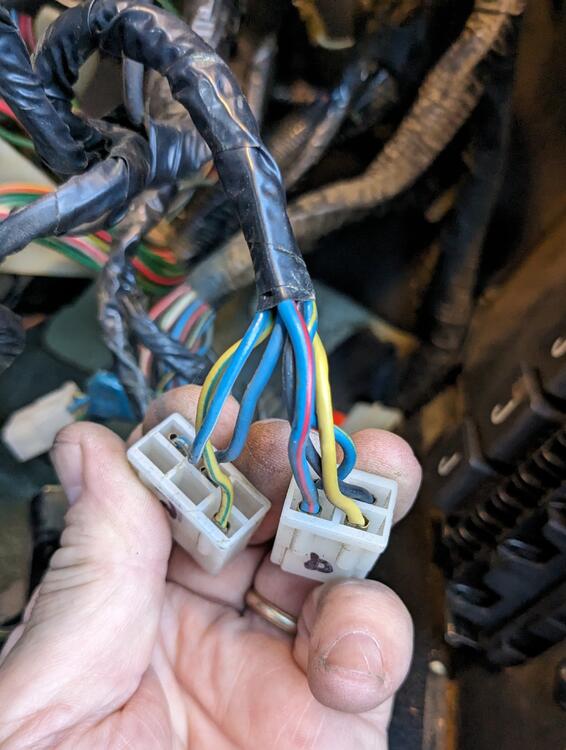

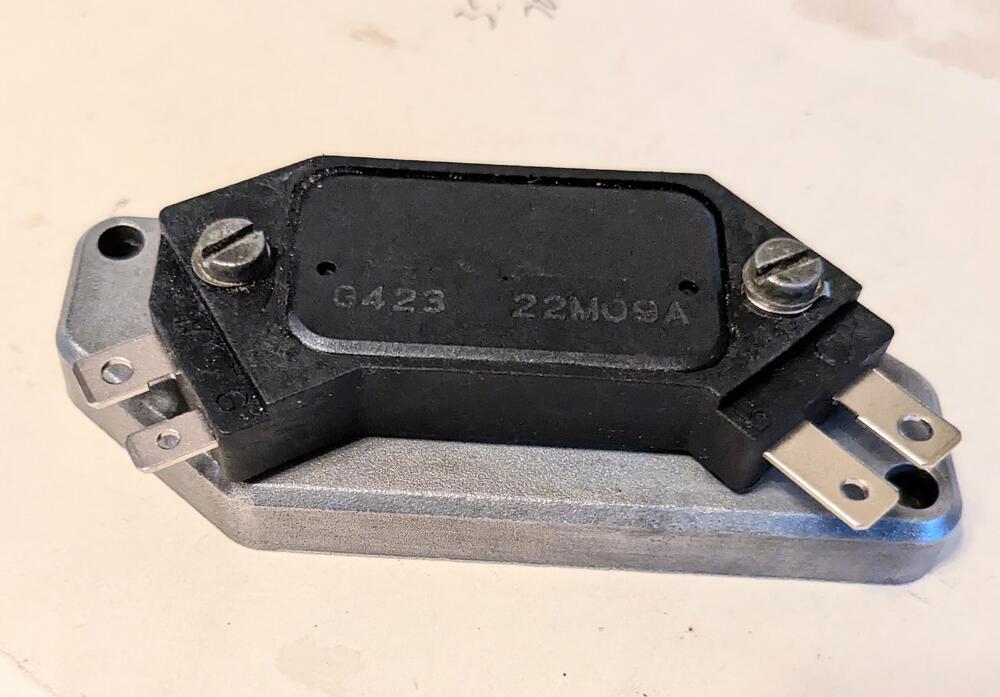

Coil (-) connection. Red-White, since that's what Volvo uses. Blue is usually (+), glad I checked what Nissan uses for (-)

Drilled (9/16") & tapped the intake for 3/8" NPT fitting

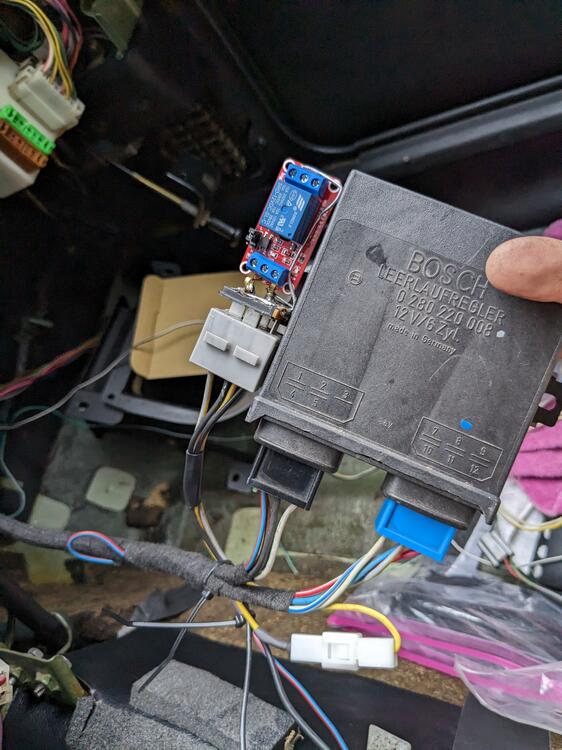

Made a support plate for the 3517886 IACV. No room for a bolt to come through the plate from above, so I welded a nut on the backside & put in a short stud to retain the IACV bracket. Re-tapped the vacuum port for the charcoal canister to 1/8" NPT & plugged it. The IACV hose passes right over it

Moved charcoal canister vacuum port to rear of plenum, using quick connect with nitrile line

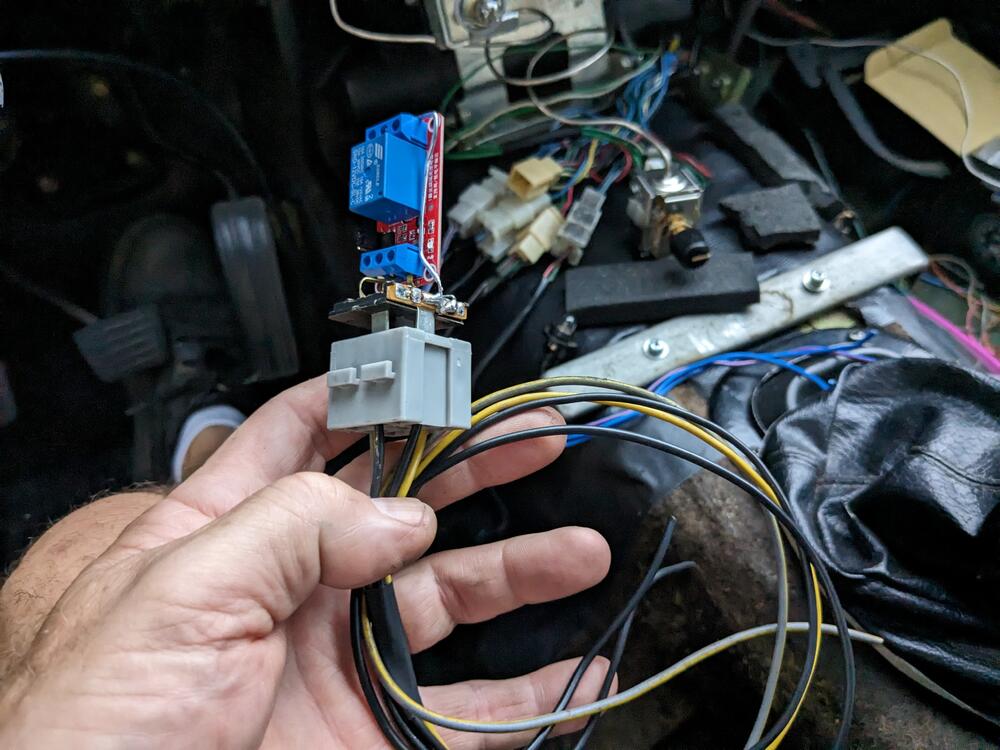

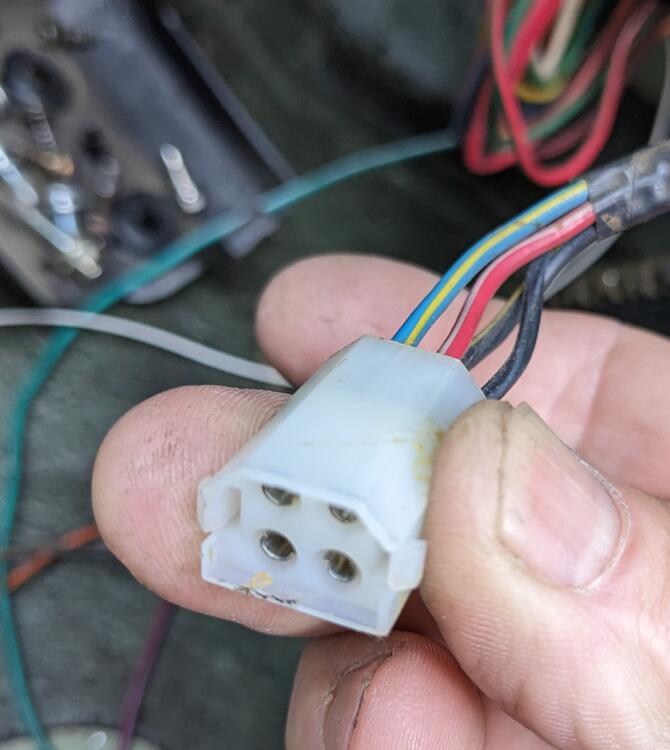

With the IACV placement sorted, I wired the 3 pole connection

and the 2 pole for the ECT, and the ground connections on intake

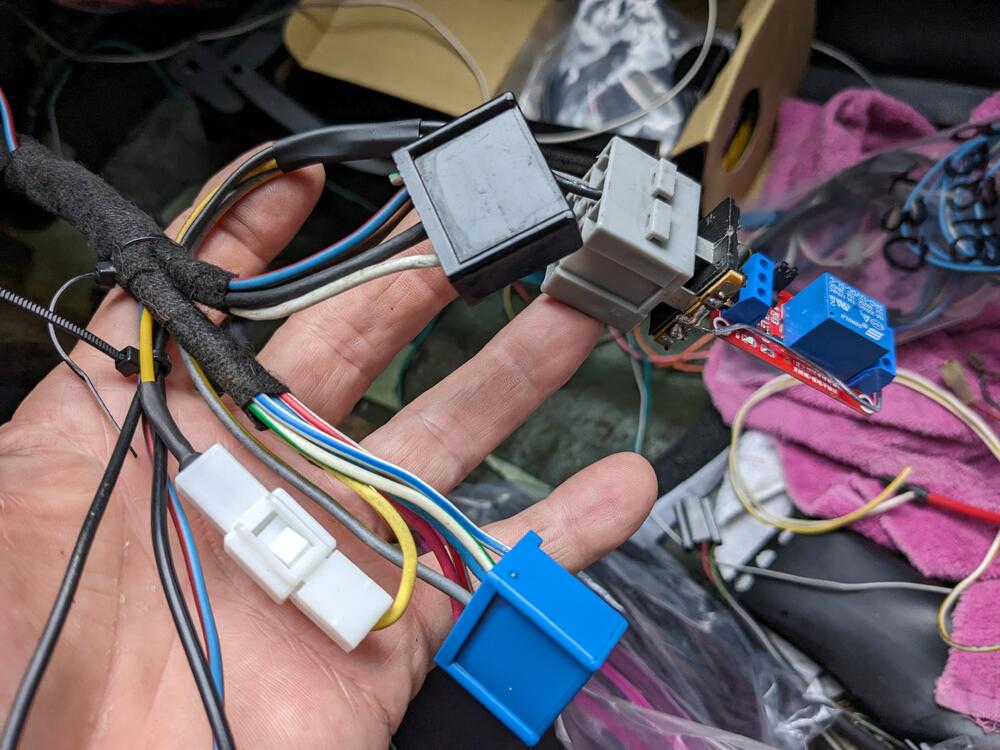

CSV placement in TB

to get a clean run on the CSV feed hose, I'm going to flip the CSV. Converting to barb fitting. I have 3 different Volvo CSV - this one has an offset connector compared to the one above

Made the block off plate for the B.C.D.D, with 3/8" NPT port for the valve cover vent. Used the B.C.D.D base gasket as the template for the mount holes

shaped somewhat, brass elbow fitted. Used HondaBond to seal plate.

B.C.D.D port re-drilled to match the greater breather vent ID above

Breather vent elbow hose fitted below will clear the TPS once reinstalled. Have to figure out a clean way to unify the valve cover port hose with this

78 280Z AAV & Breather vent hose layout for ref.

Coil (-) connection. Red-White, since that's what Volvo uses. Blue is usually (+), glad I checked what Nissan uses for (-)

Drilled (9/16") & tapped the intake for 3/8" NPT fitting

Made a support plate for the 3517886 IACV. No room for a bolt to come through the plate from above, so I welded a nut on the backside & put in a short stud to retain the IACV bracket. Re-tapped the vacuum port for the charcoal canister to 1/8" NPT & plugged it. The IACV hose passes right over it

Moved charcoal canister vacuum port to rear of plenum, using quick connect with nitrile line

With the IACV placement sorted, I wired the 3 pole connection

and the 2 pole for the ECT, and the ground connections on intake

CSV placement in TB

to get a clean run on the CSV feed hose, I'm going to flip the CSV. Converting to barb fitting. I have 3 different Volvo CSV - this one has an offset connector compared to the one above

Made the block off plate for the B.C.D.D, with 3/8" NPT port for the valve cover vent. Used the B.C.D.D base gasket as the template for the mount holes

shaped somewhat, brass elbow fitted. Used HondaBond to seal plate.

B.C.D.D port re-drilled to match the greater breather vent ID above

Breather vent elbow hose fitted below will clear the TPS once reinstalled. Have to figure out a clean way to unify the valve cover port hose with this

78 280Z AAV & Breather vent hose layout for ref.

Last edited: