lookforjoe

True Classic

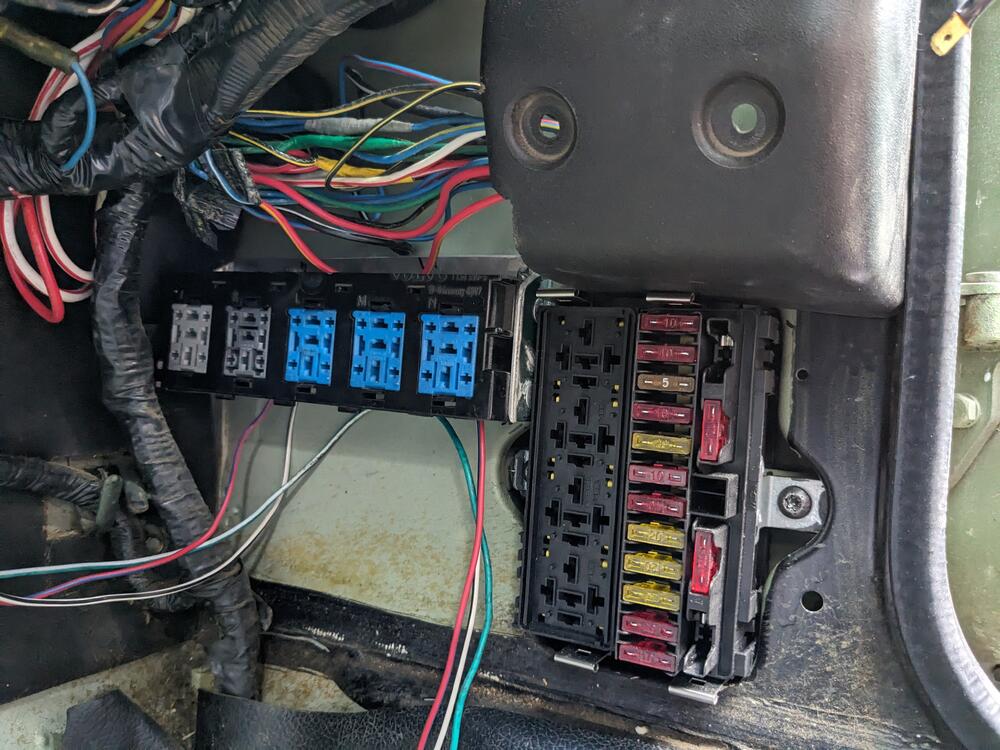

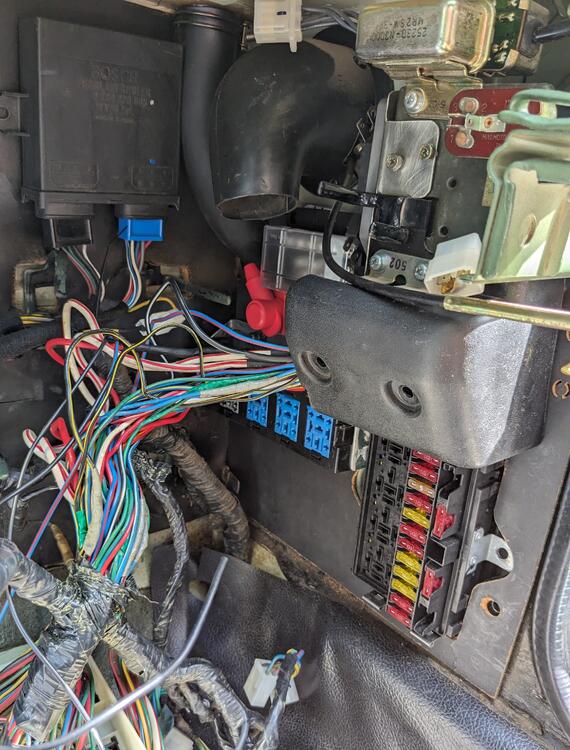

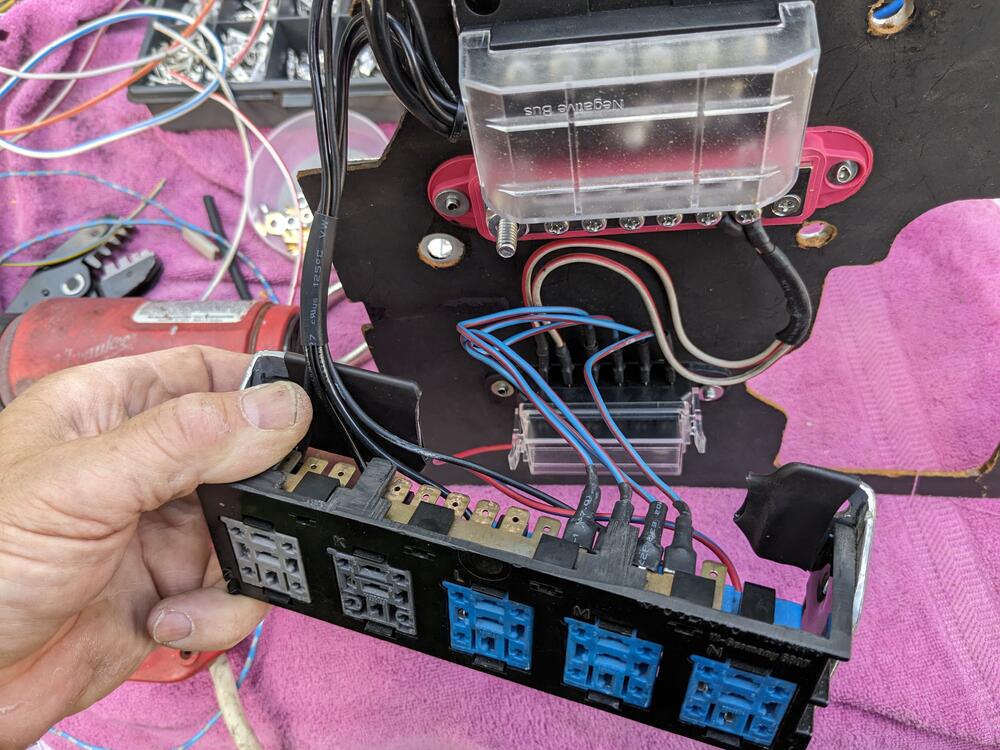

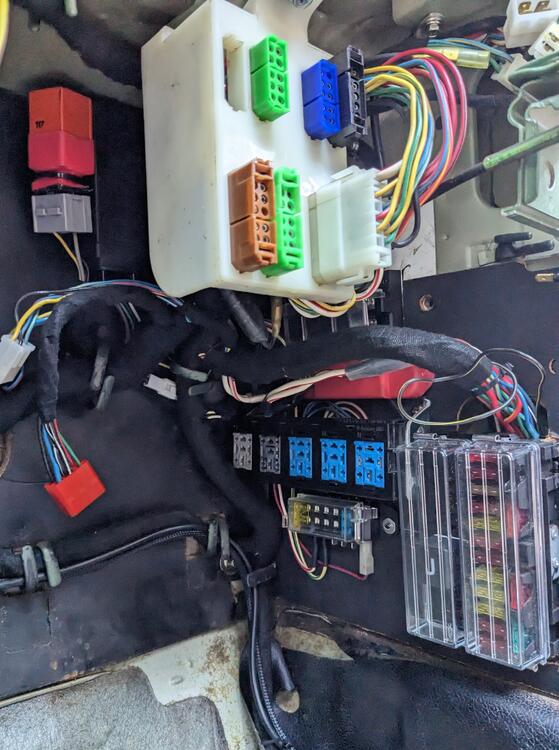

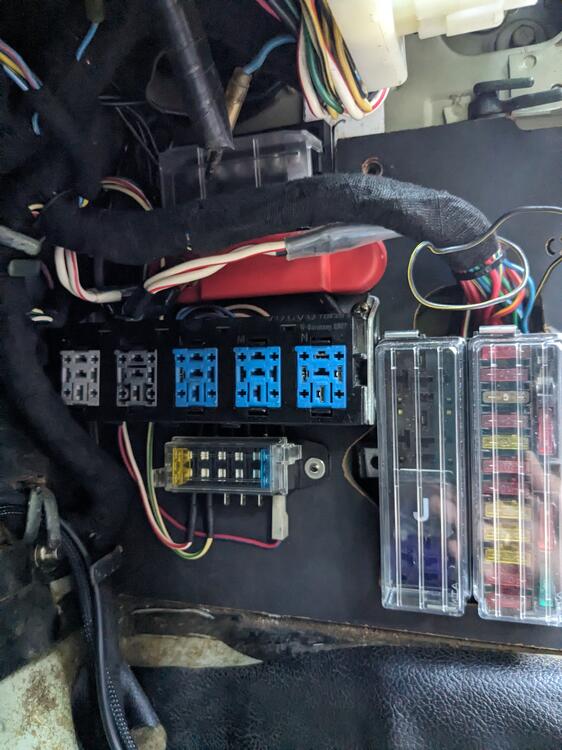

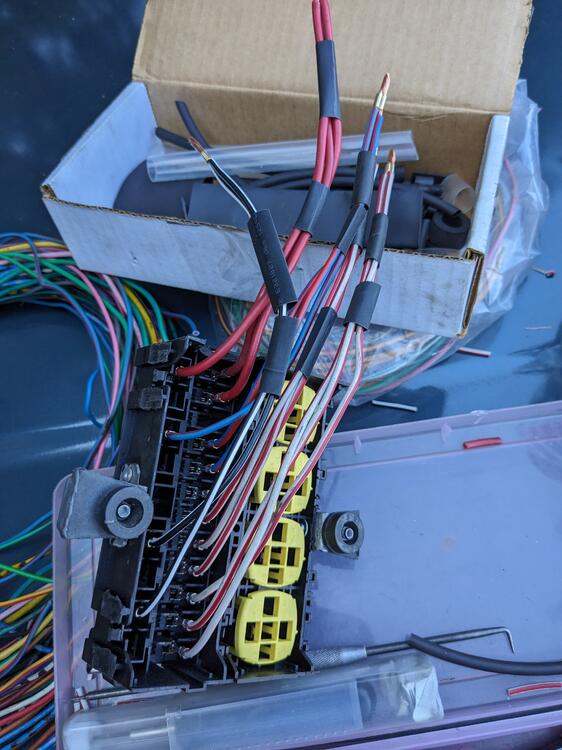

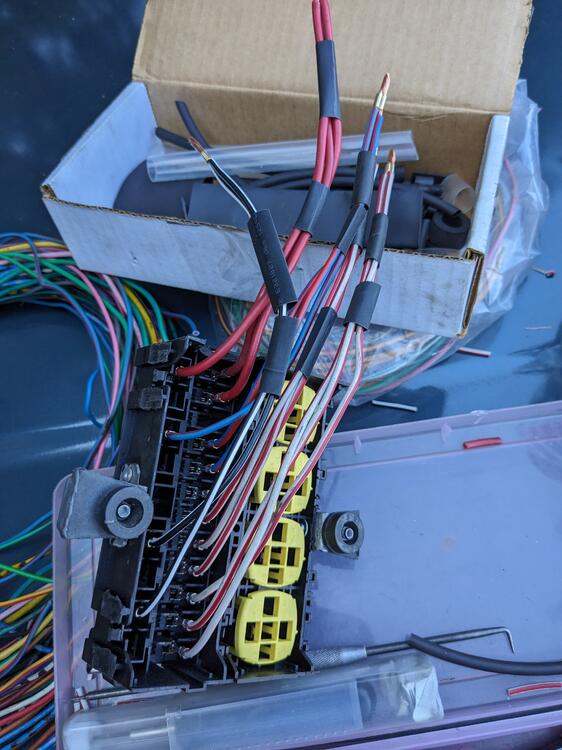

Cut out the Fusebox today & wired the Hella (MTA) 16 position ATC fuse panel in

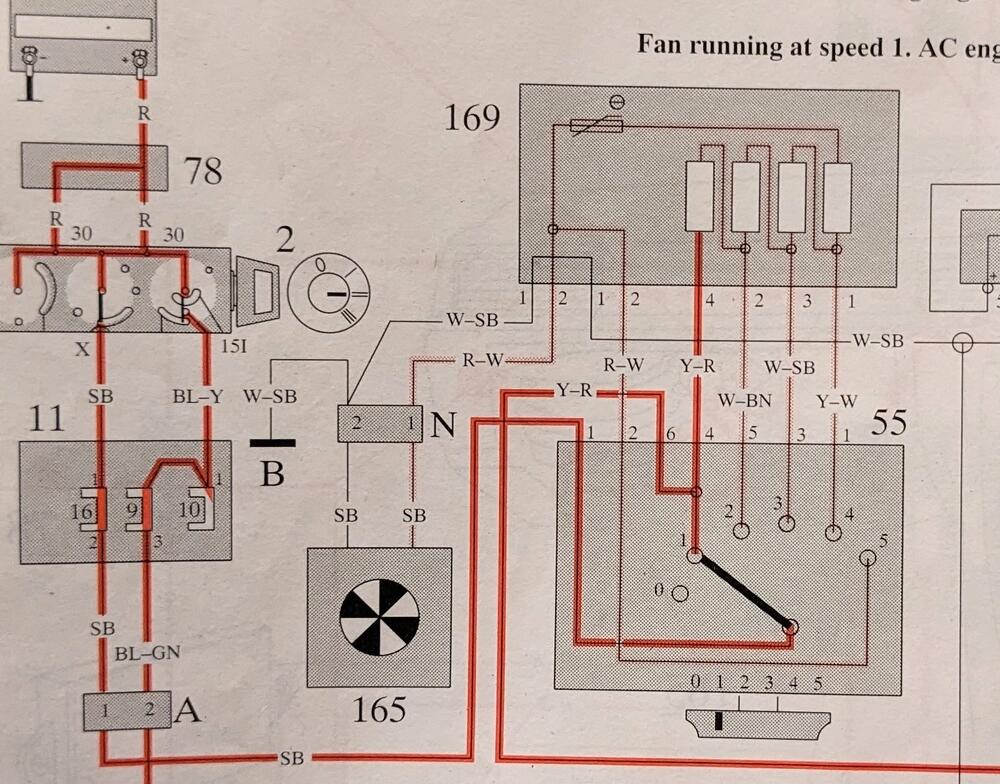

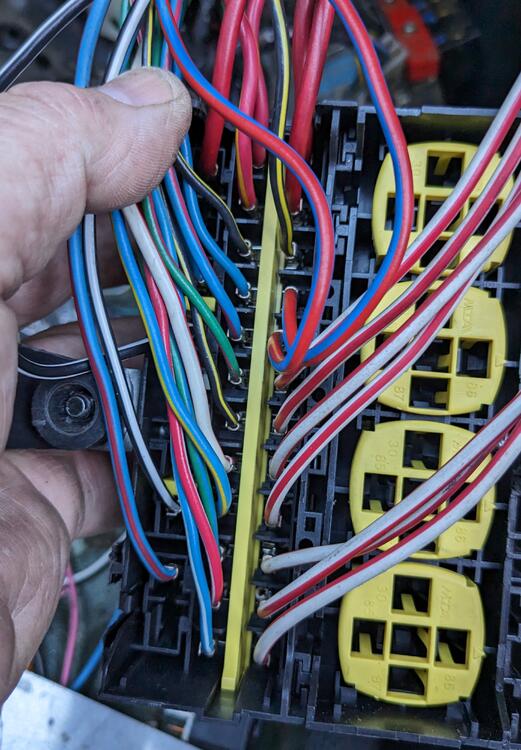

Noting the grouped inputs

I batched the fuses following the input groupings above (14 total)

3 Red (1 spare) Lighting

2 Black-white ?

3 Blue-red (1 spare) Acc (15+)

4 White-red (30)

3 White-red (30)

1 Black-yellow (50)

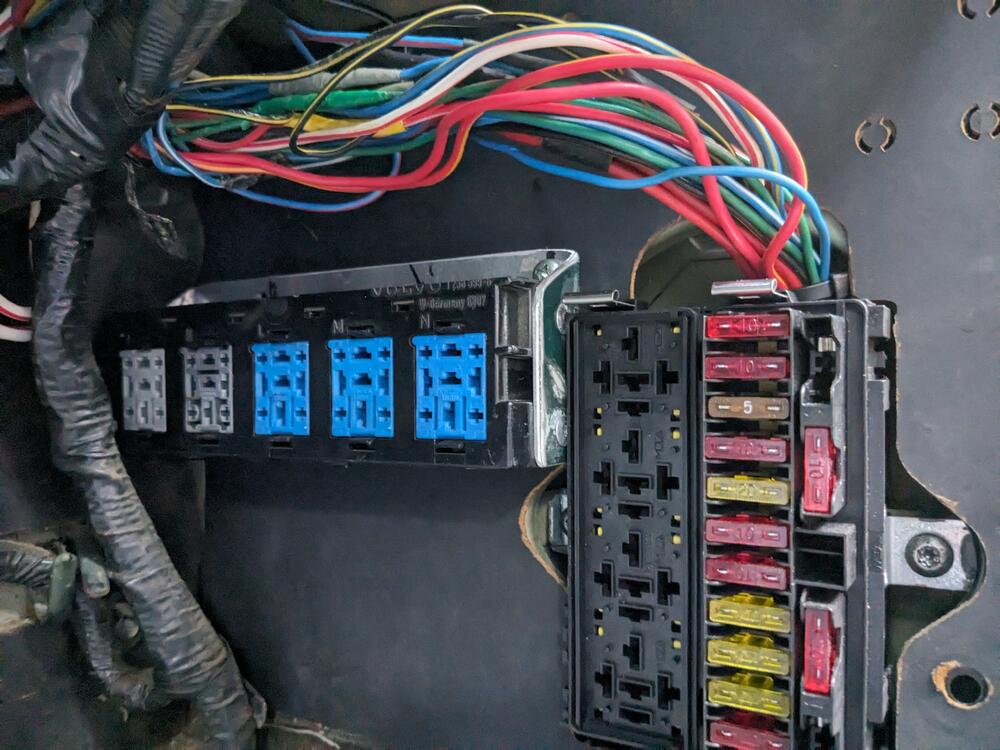

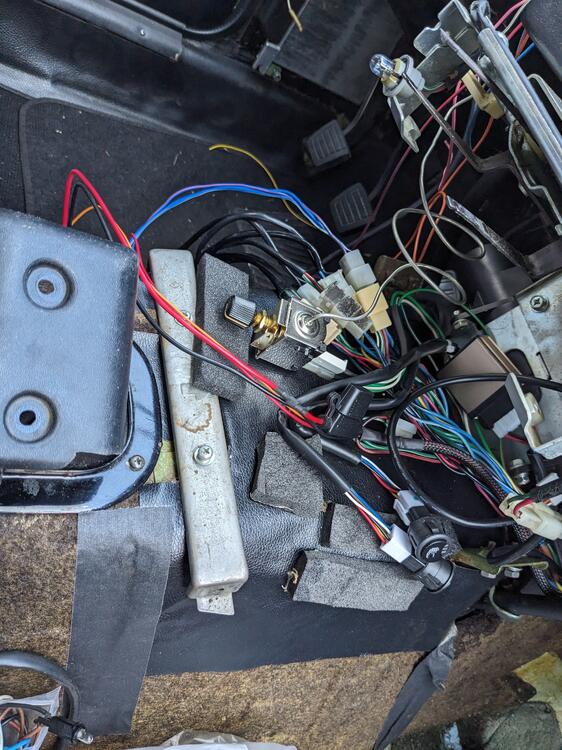

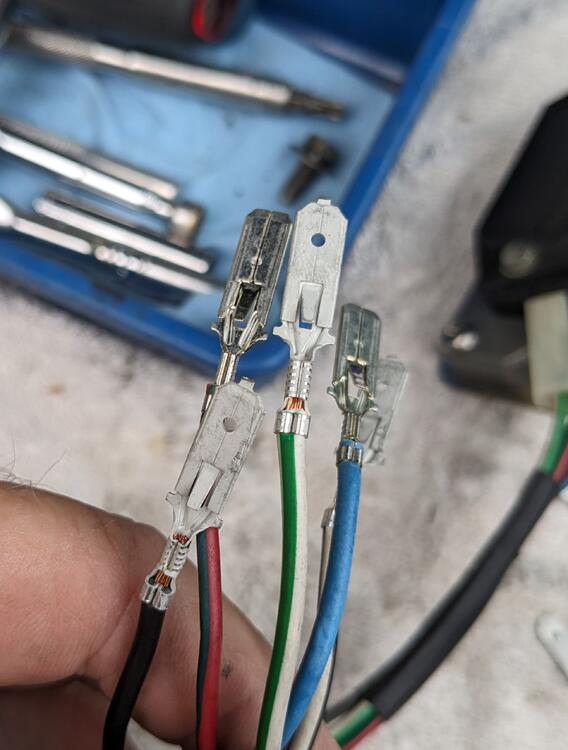

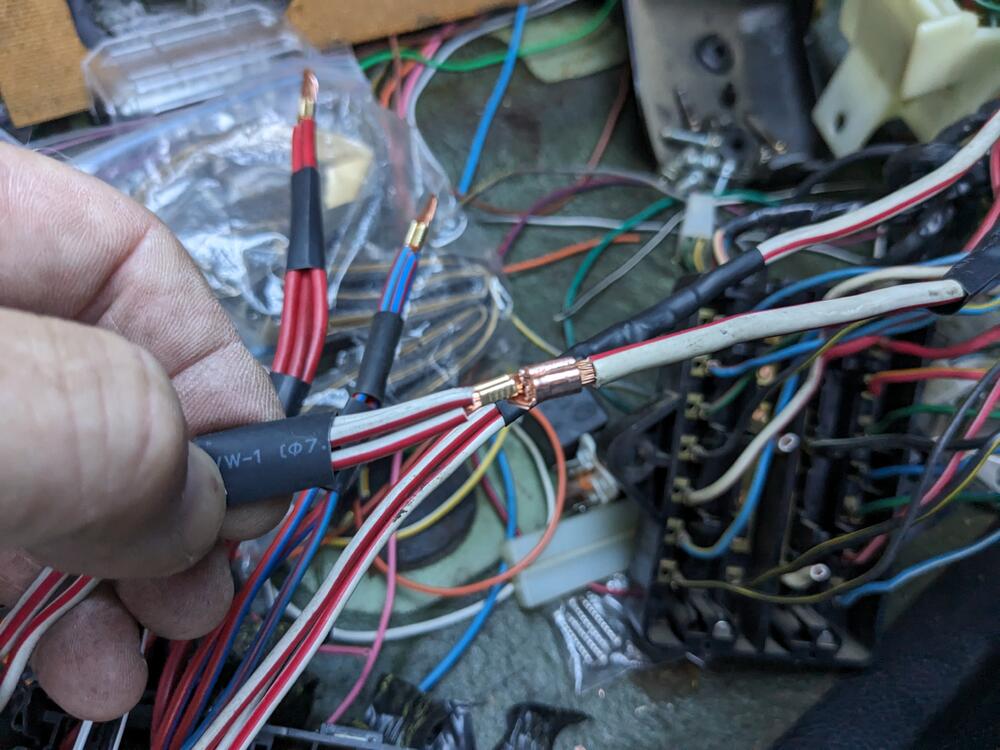

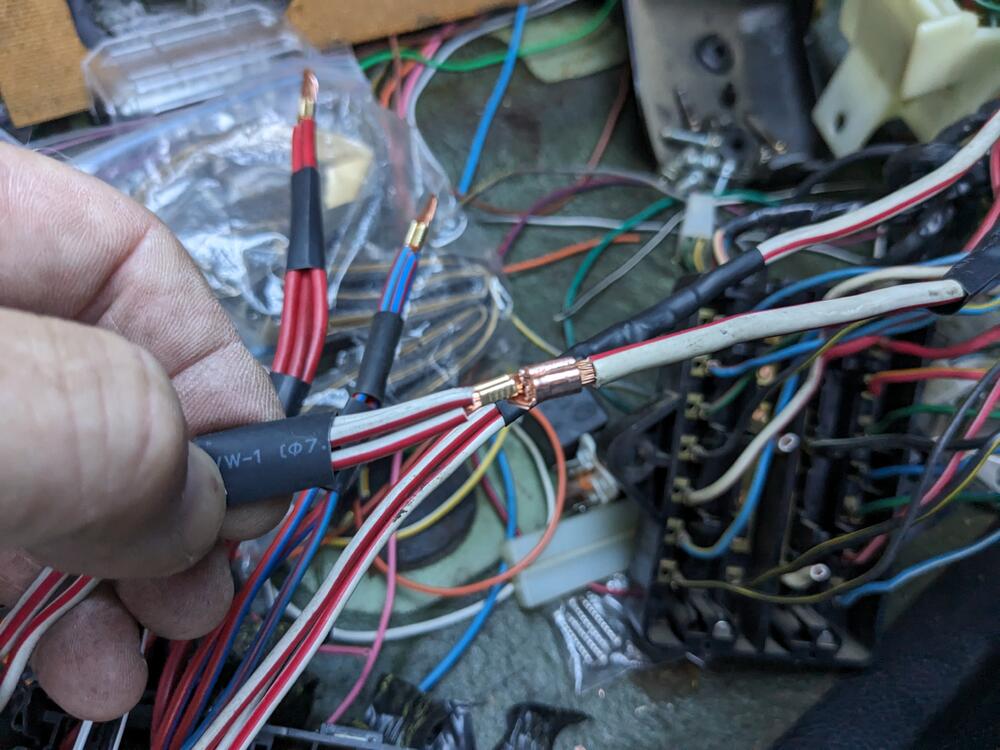

No space to batch within the fuse panel, so the splices are outside the box. Small crimp to unify individual wires

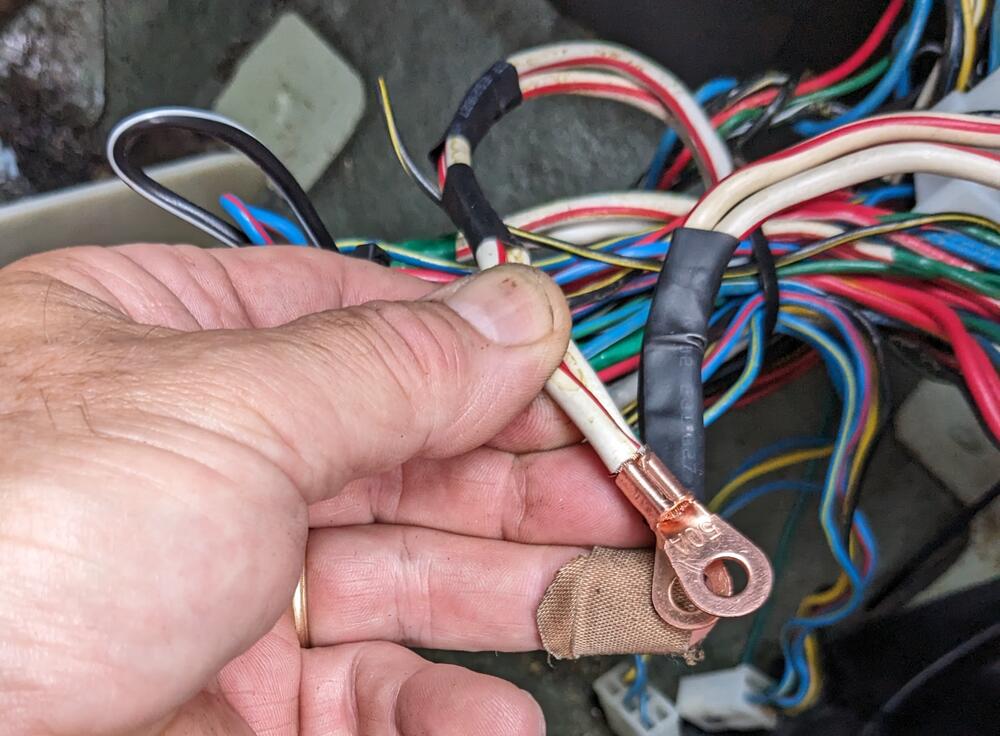

Larger crimp to join feed wires

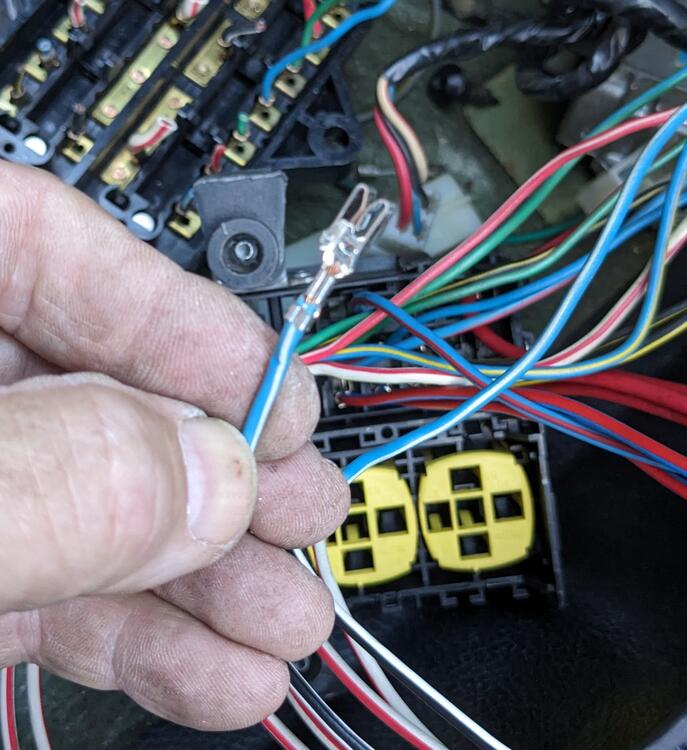

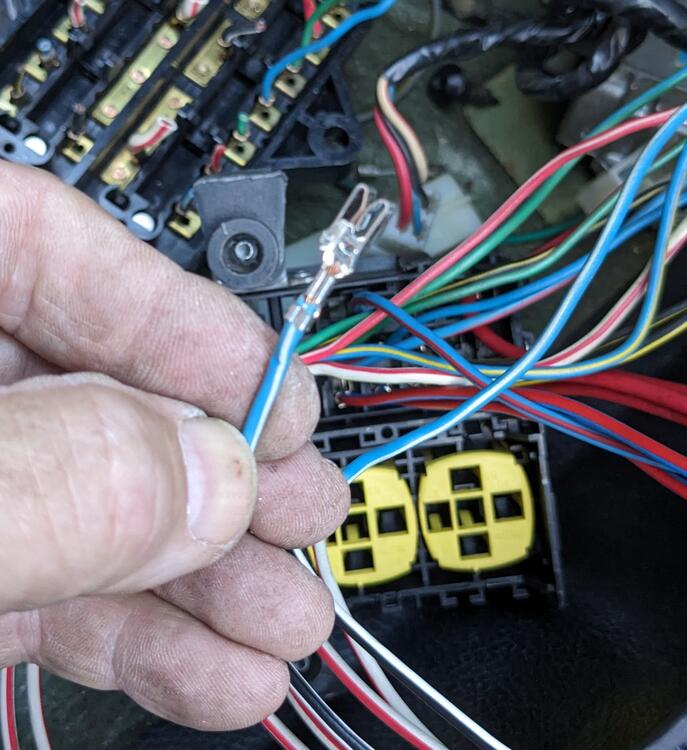

individual circuits added in decending order

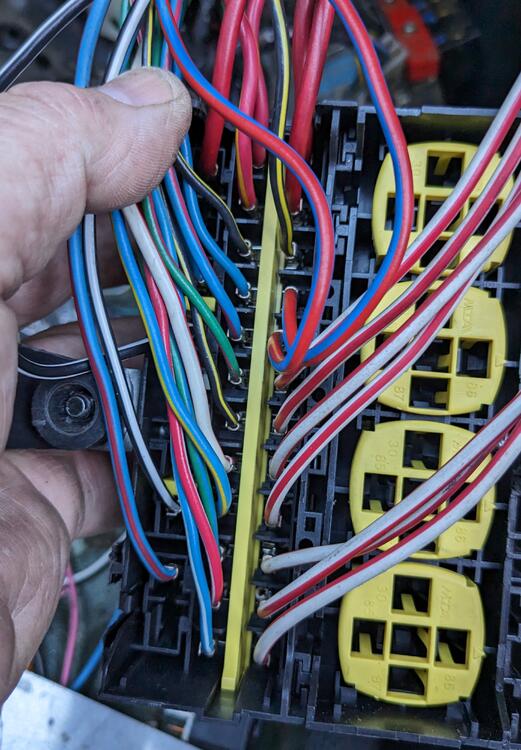

separator/ pin retainer in place

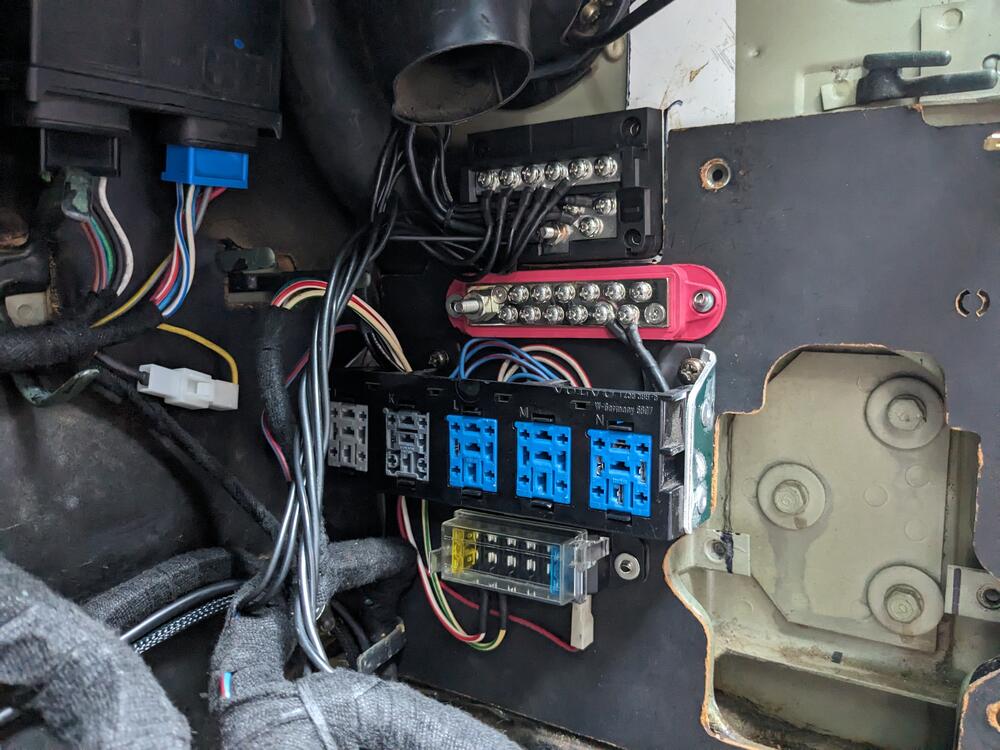

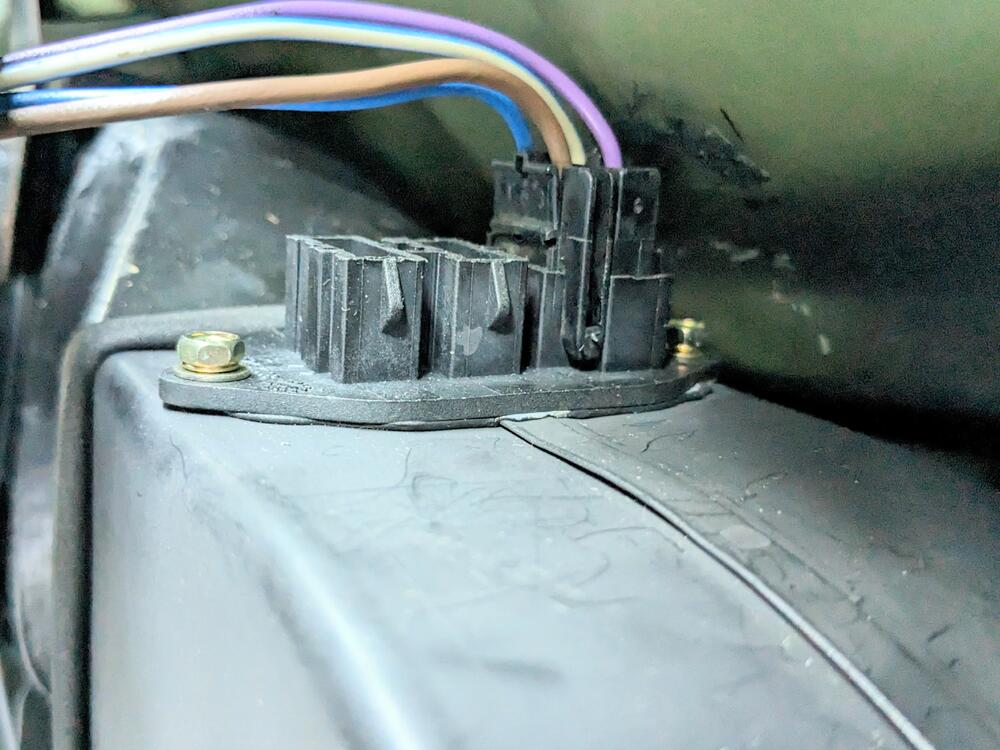

added spacers to the mount brackets - the door hinge bolt heads are otherwise too close to the wiring passing behind

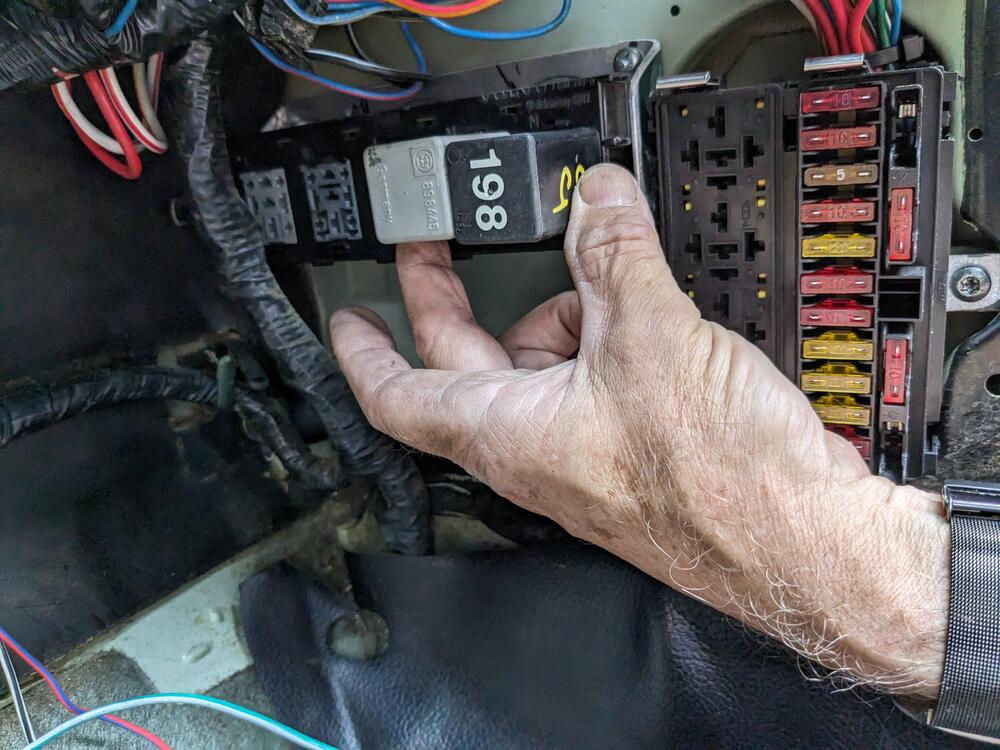

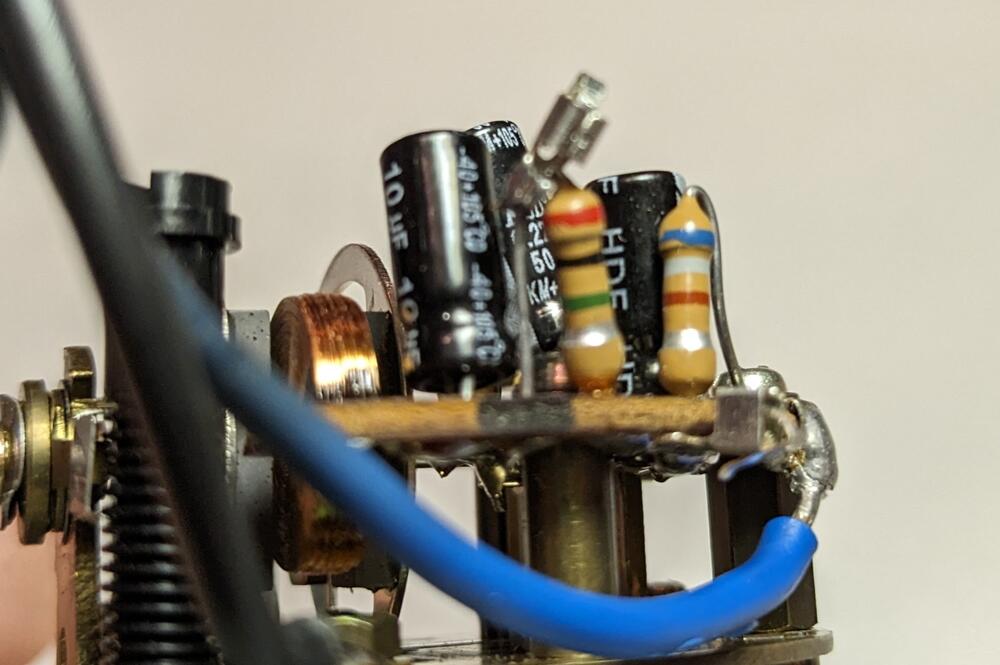

annoying thing is that only standard cube relays will fit, not the rectangular ones I have for the AC delay & Interval, so those have to go elsewhere. The only one I need to add here right now is the relay to switch the blower on when the AC is engaged.

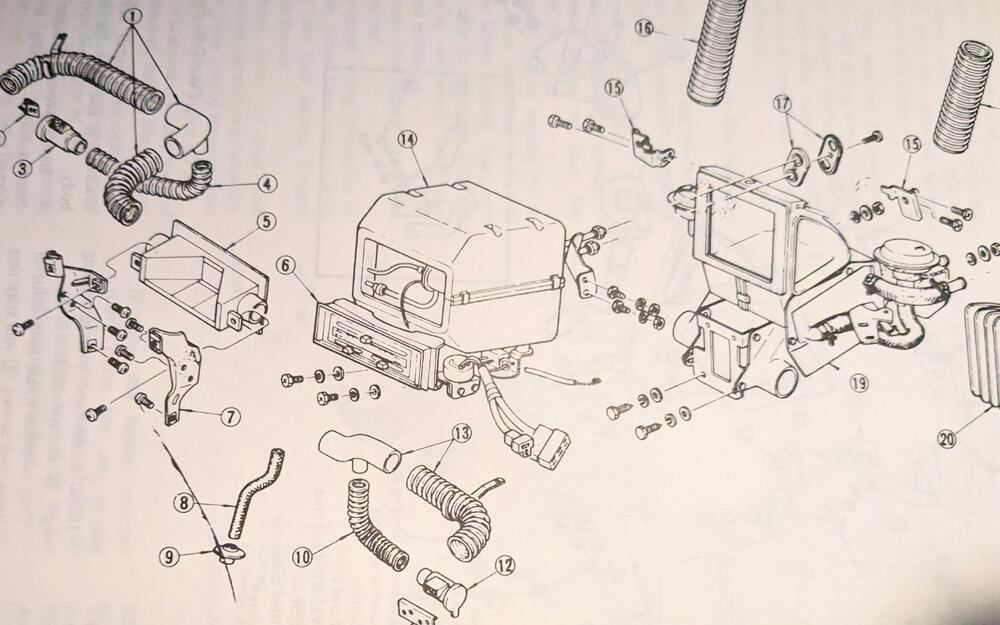

Noting the grouped inputs

I batched the fuses following the input groupings above (14 total)

3 Red (1 spare) Lighting

2 Black-white ?

3 Blue-red (1 spare) Acc (15+)

4 White-red (30)

3 White-red (30)

1 Black-yellow (50)

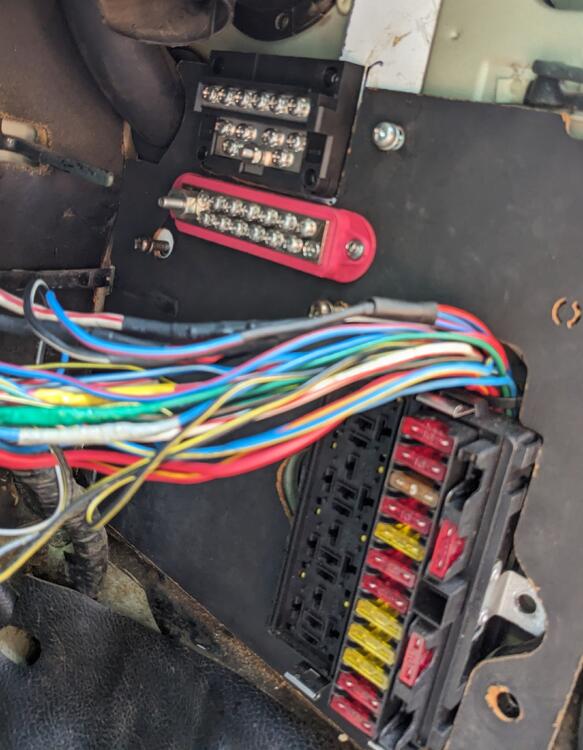

No space to batch within the fuse panel, so the splices are outside the box. Small crimp to unify individual wires

Larger crimp to join feed wires

individual circuits added in decending order

separator/ pin retainer in place

added spacers to the mount brackets - the door hinge bolt heads are otherwise too close to the wiring passing behind

annoying thing is that only standard cube relays will fit, not the rectangular ones I have for the AC delay & Interval, so those have to go elsewhere. The only one I need to add here right now is the relay to switch the blower on when the AC is engaged.

Last edited: