You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Transmission overhaul, 5 speed

- Thread starter beezee

- Start date

Steve Hoelscher

True Classic

The cases get thoroughly cleaned. Then media blasted to get the oxidation off. I then paint them with a specific paint I found that leaves a good finish that looks normal. I like the paint because the bare aluminum collects dirt and oil that is hard to clean. This paint leaves a smooth finish that is easy to clean. Spray it with a light degreaser and it rinses clean with water.

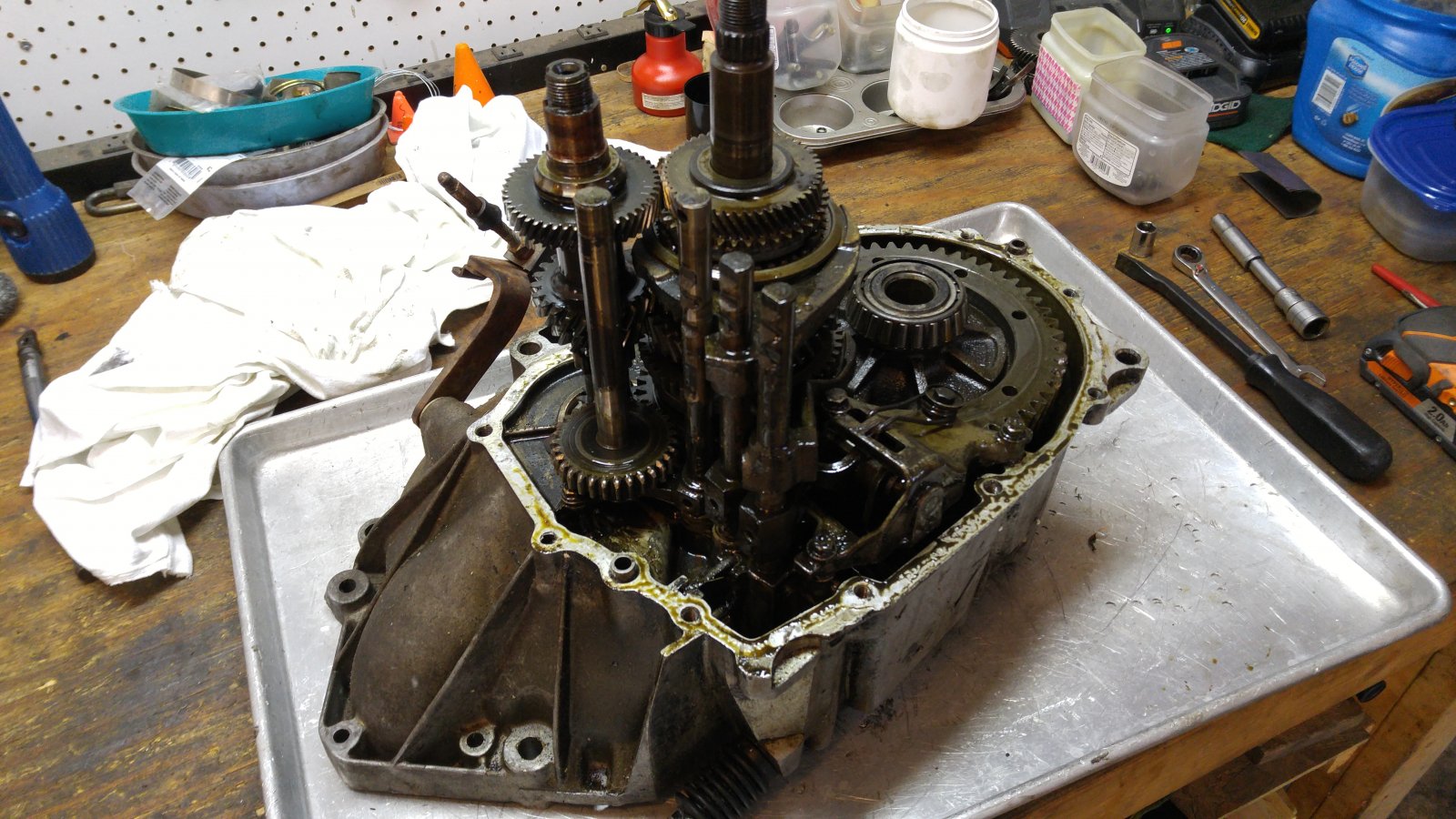

This is the typical starting point:

Very nasty:

After cleaning and ready for paint:

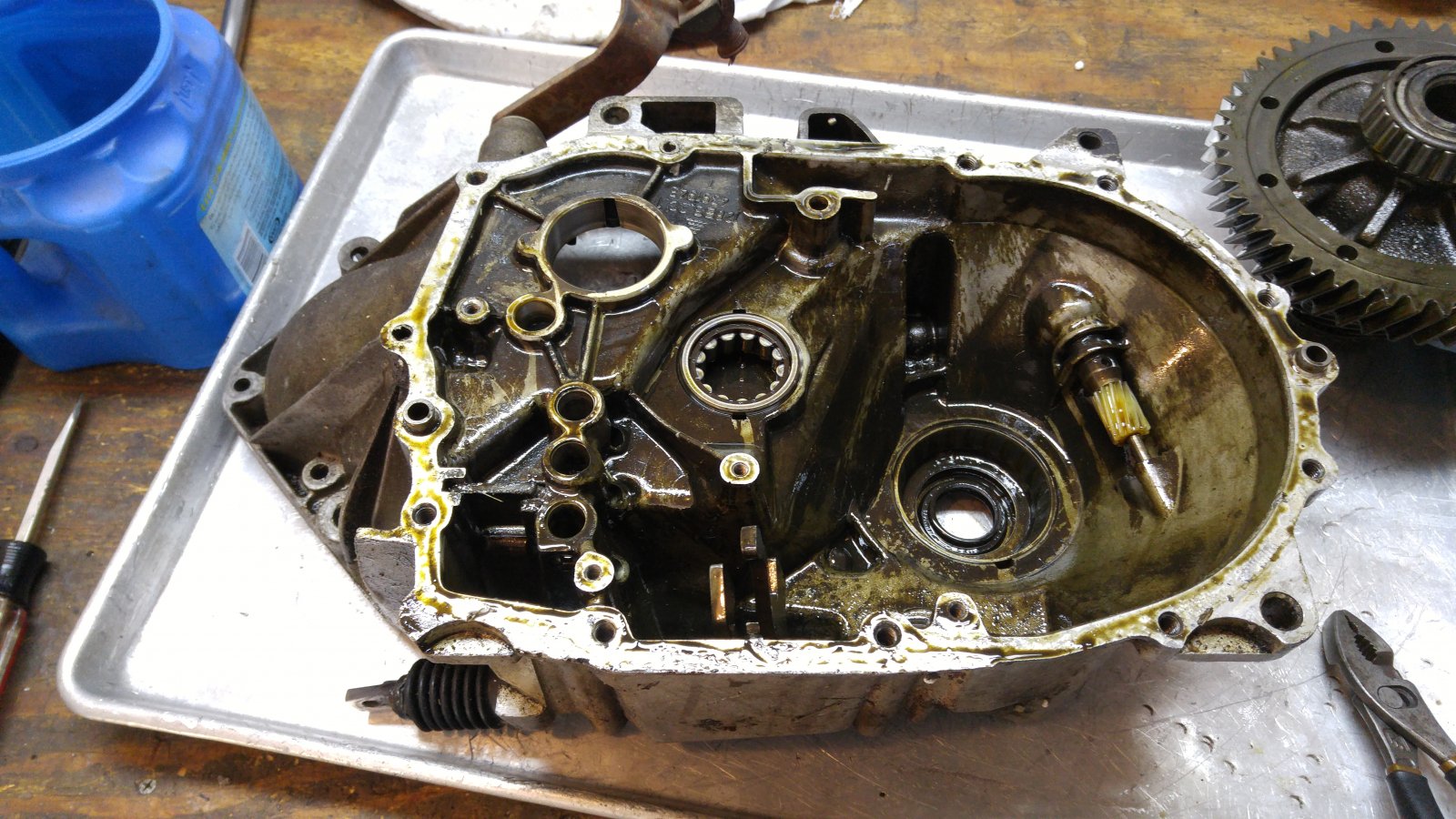

Setting up the diff is a critical part of the build. You can see in this photo how the contaminated gear oil stained the case:

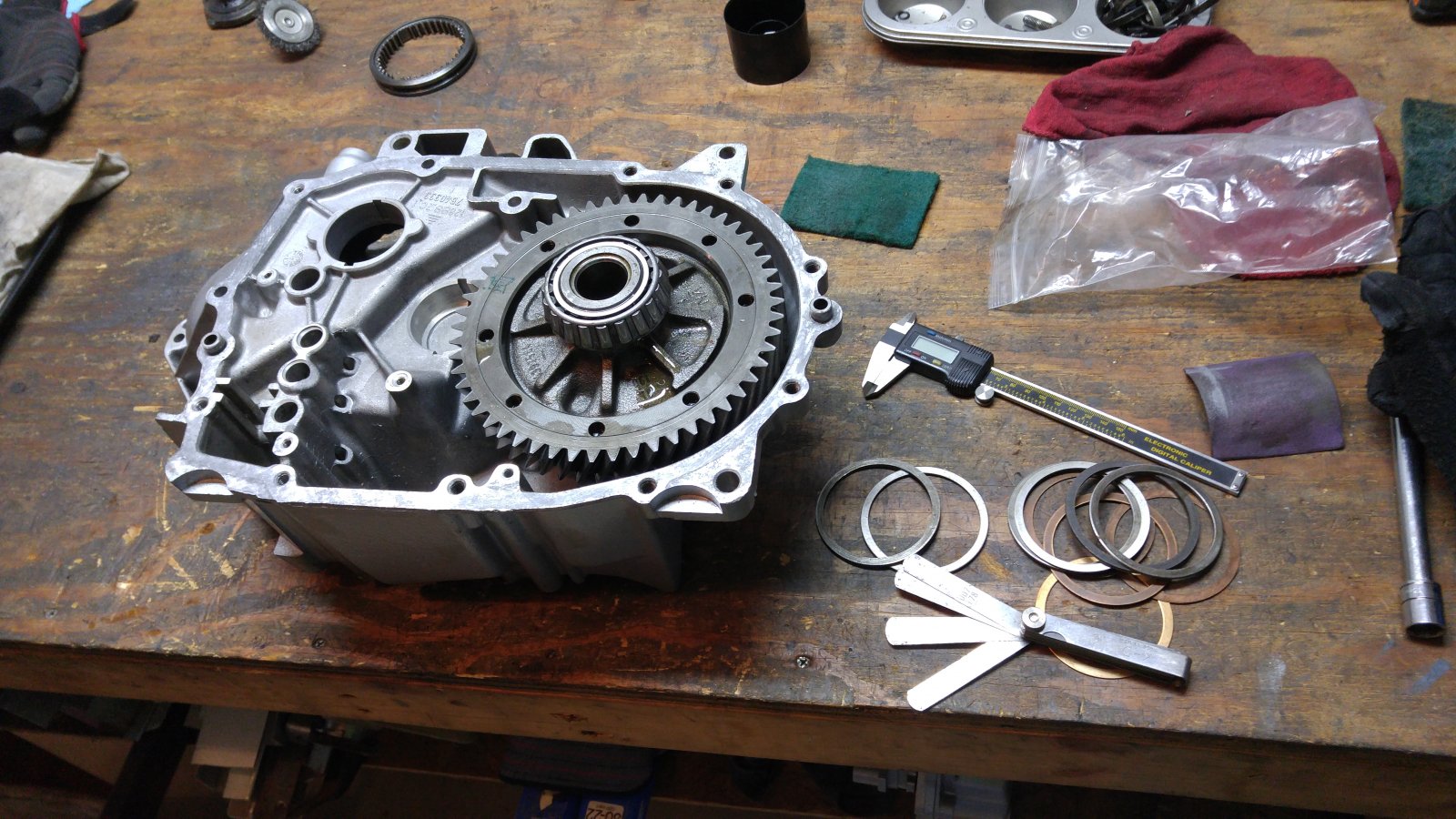

Shimming to spec:

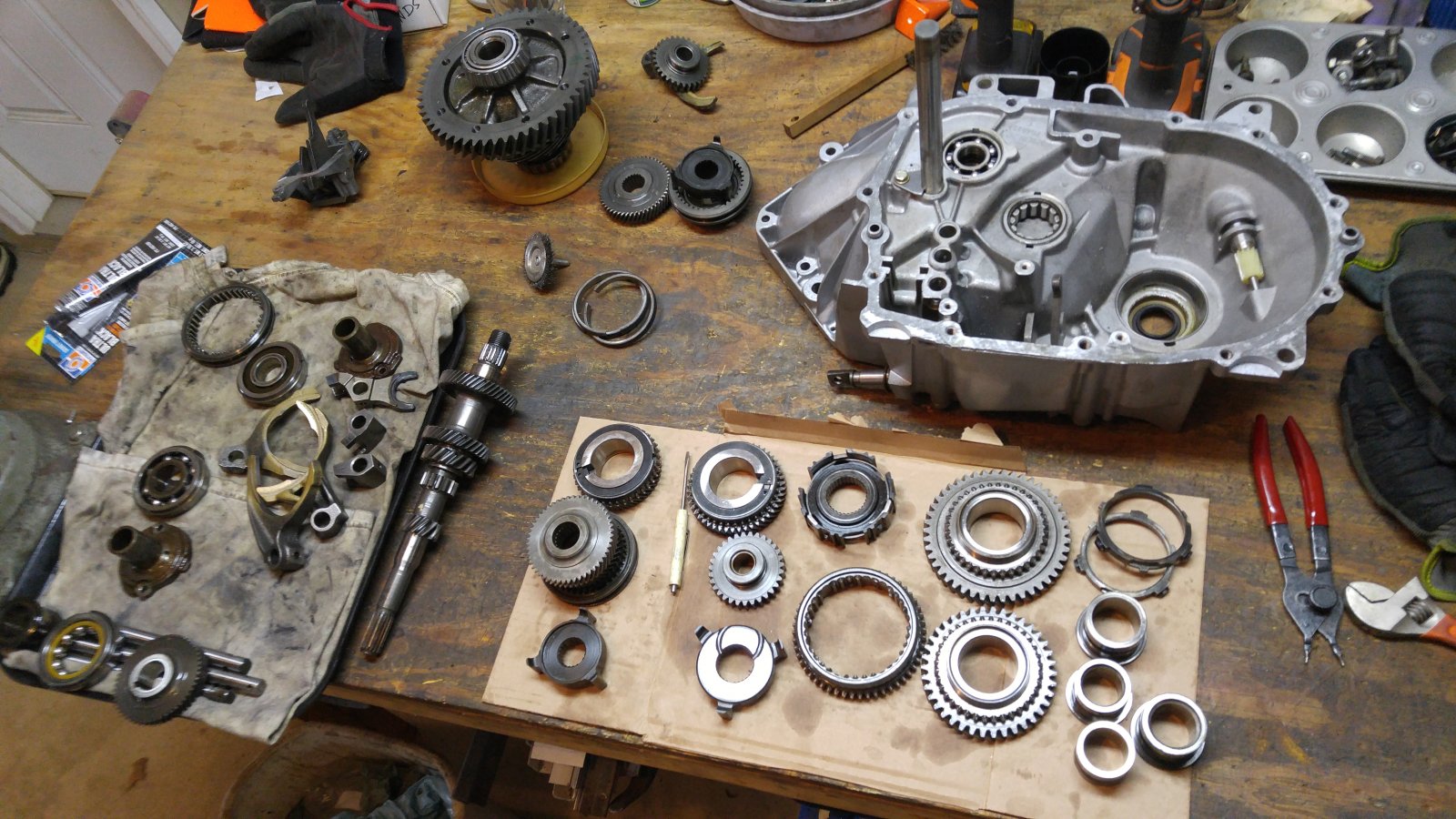

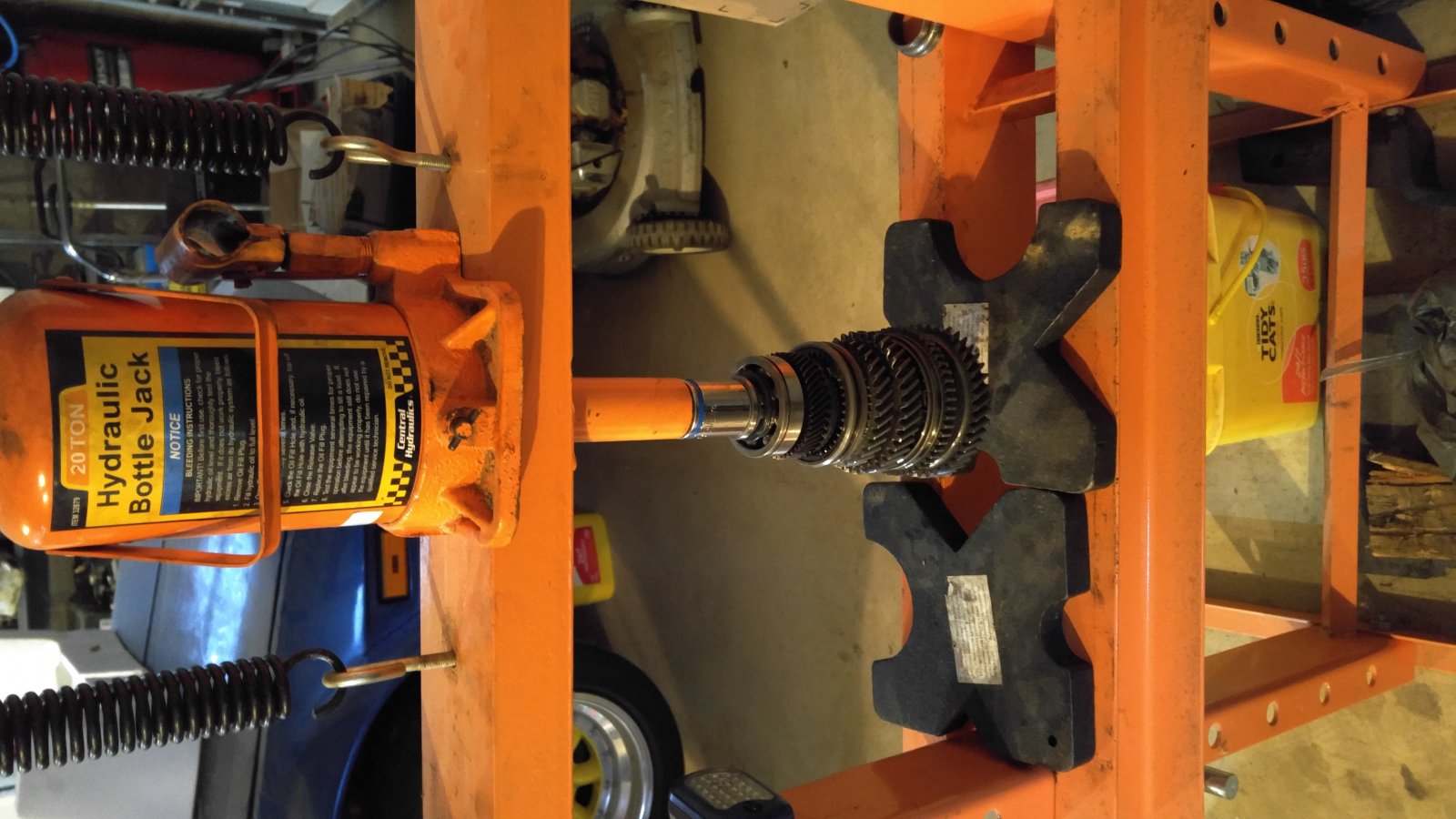

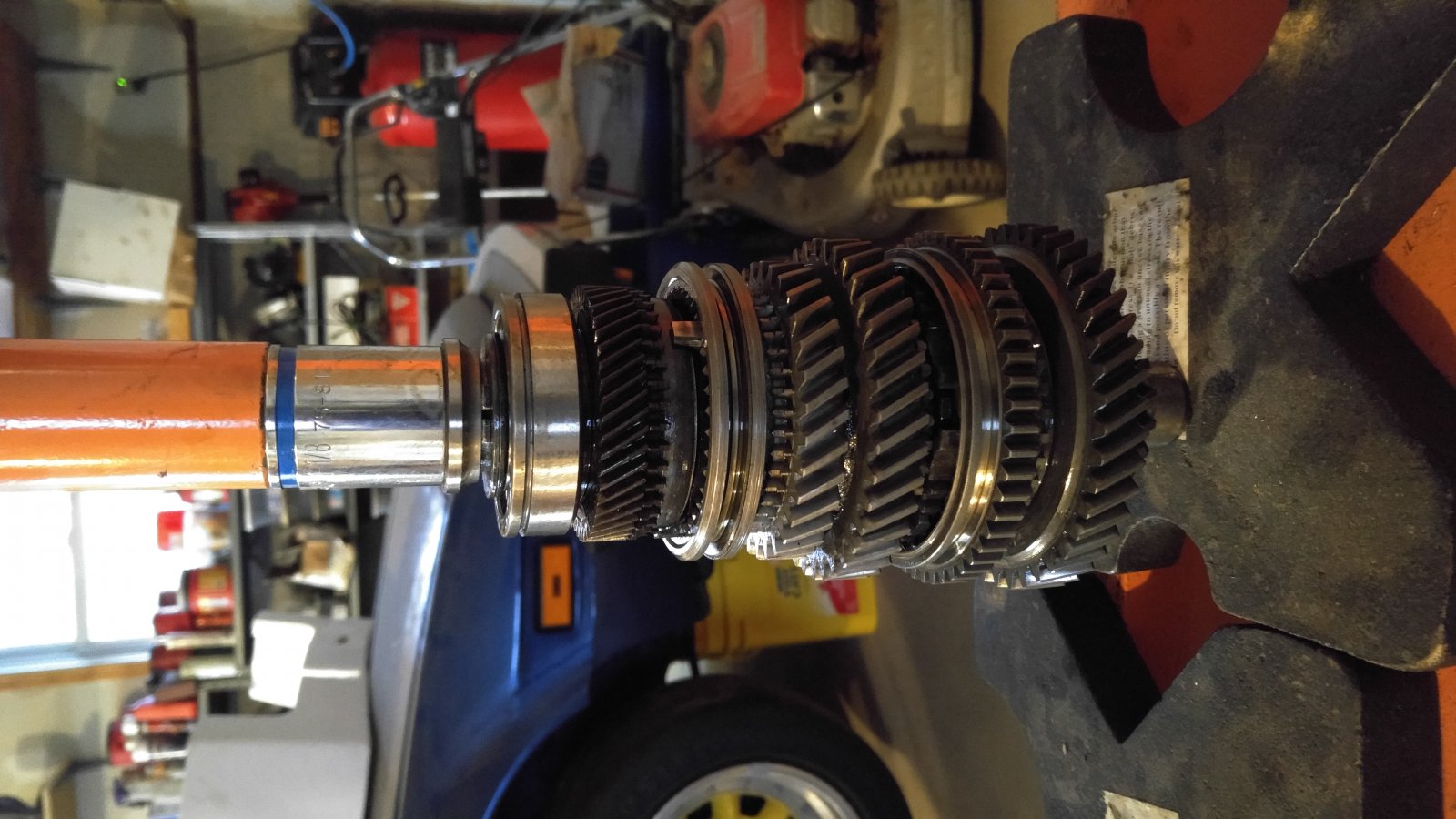

The case is built, the diff built and shimmed and the sub-assemblies complete, I am ready to stack the gearset:

Gearset ready to install:

This is the typical starting point:

Very nasty:

After cleaning and ready for paint:

Setting up the diff is a critical part of the build. You can see in this photo how the contaminated gear oil stained the case:

Shimming to spec:

The case is built, the diff built and shimmed and the sub-assemblies complete, I am ready to stack the gearset:

Gearset ready to install:

beezee

True Classic

Thanks for posting the photos Steve. My transmission cases came up pretty clean so I've elected to leave them unpainted. The inside of that transmission is really grungy. I would expect to see that amount of filth in an engine where combustion is taking place, but I wouldn't expect it in a transmission. I suppose that unlike an engine, the transmission may never see an oil change.

Now for a question:

I am replacing the differential bearings in my transmission this time around. They didn't look bad, but I've decided to replace them as I don't want to risk having to take the transmission out of the car a third time. When measuring the bearing preload, can I assume the gasket needs to be installed? I haven't seen this mentioned in any of the instructions, workshop manual or otherwise.

Brian

Now for a question:

I am replacing the differential bearings in my transmission this time around. They didn't look bad, but I've decided to replace them as I don't want to risk having to take the transmission out of the car a third time. When measuring the bearing preload, can I assume the gasket needs to be installed? I haven't seen this mentioned in any of the instructions, workshop manual or otherwise.

Brian

Steve Hoelscher

True Classic

Yes, if you are going to use a gasket on final assembly you will need to set the preload with the gasket. Important to note that different vendors gaskets are often different thickness. Since the spec on preload is fairly narrow different gaskets can change the preload.

fiatfactory

Steve Cecchele

A question for Steve H if he has the time to answer...

I just ran into (what I think is) a very unusual failure in a five speed transmission, the splined section of the differential side gear appears to have broken away from the rest of the side gear and allowed the axle to lose drive, stopping the car from moving... in a way I guess this was fortunate as there doesn't appear to be any other damage (though I haven't removed and opened the casing up yet)

Have you seen this type of failure before? Any ideas as to what might have caused this if you have?

SteveC

I just ran into (what I think is) a very unusual failure in a five speed transmission, the splined section of the differential side gear appears to have broken away from the rest of the side gear and allowed the axle to lose drive, stopping the car from moving... in a way I guess this was fortunate as there doesn't appear to be any other damage (though I haven't removed and opened the casing up yet)

Have you seen this type of failure before? Any ideas as to what might have caused this if you have?

SteveC

Paul Valente

Automotive Engineer

The inside of that transmission is really grungy. I would expect to see that amount of filth in an engine where combustion is taking place, but I wouldn't expect it in a transmission. I suppose that unlike an engine, the transmission may never see an oil change.

Brian

Unlike the engine, the transmission does not have a pressurized oil system with a filter so the fluid specified is non-detergent. One of the goals of detergents in oils is to keep debris suspended so that it can be filtered out. For non-detergent oils, you want the debris to fall out of suspension and stick to the bottom or walls or a magnet so that the debris doesn't circulate around ruining stuff. So often times you see a lot of nasty looking parts while the oil itself doesn't look so bad. I work on axles a lot and it is the same scenario.

Also, you could use RTV on that joint with a high degree of success. Cleanliness is important but it appears from Steve's pictures that the parts are designed to be compatible with a liquid gasket (see the chamfer?). EP additives are very surface-active and are aggressive with the RTV so make sure you use the correct oil. One advantage of the RTV joint is that there is metal-to-metal contact so the diff bearing preload will be very stable. With a paper gasket, if it creeps .001" you loose a thou of preload. Looks like Steve has a fresh tube of Ultra Black which I have used with good success (albeit in other applications).

Some pictures of my Beta transmission here which has a similar joint design on the diff cover....note the Beta splits the bearing bore which differs from the X.

https://xwebforums.com/forum/index.php?threads/on-liquid-gaskets-and-their-application.32537/

Steve Hoelscher

True Classic

Steve, I would love to see a photo of the failed part. If I understand the failure you describe that is indeed a very unusual one. The side gear, pictured below is a single machined piece without an apparent weakness that would point to such a failure.

I have never seen such a failure in an X1/9 Diff. I assume this is a 5 speed? There are two basic diff failures I see: 1) Diff explosions: I have blown up several and have seen a few others. This is usually the result of a hard launch or 1-2 upshift in a car that makes considerably more torque than stock. The diff carrier housing cannot support the torque load from the spider gears driving the side gears. The housing fractures and the two halves separate with explosive force. This was such a regular occurrence on my autocross car that I carried a spare transmission with me. The entire differential section of the case would be blown away leaving the two stub axles hanging in the now empty space. 2) Pinion shaft/spider and/or side gear wear: Common on cars driven in ice/snow or off-road. Spinning one wheel excessively will overheat the point where the spider gear rides on the pinion shaft and wear the mating surfaces until it either seizes or becomes sloppy. When this happens the teeth will fail. Of course it is making a lot of noise too. The came failure I sometimes see on poorly setup track cars. They spin the inside rear on corner exit repeatedly. The high temps and wheel spin result in the same problem/failure.

I have never seen such a failure in an X1/9 Diff. I assume this is a 5 speed? There are two basic diff failures I see: 1) Diff explosions: I have blown up several and have seen a few others. This is usually the result of a hard launch or 1-2 upshift in a car that makes considerably more torque than stock. The diff carrier housing cannot support the torque load from the spider gears driving the side gears. The housing fractures and the two halves separate with explosive force. This was such a regular occurrence on my autocross car that I carried a spare transmission with me. The entire differential section of the case would be blown away leaving the two stub axles hanging in the now empty space. 2) Pinion shaft/spider and/or side gear wear: Common on cars driven in ice/snow or off-road. Spinning one wheel excessively will overheat the point where the spider gear rides on the pinion shaft and wear the mating surfaces until it either seizes or becomes sloppy. When this happens the teeth will fail. Of course it is making a lot of noise too. The came failure I sometimes see on poorly setup track cars. They spin the inside rear on corner exit repeatedly. The high temps and wheel spin result in the same problem/failure.

Steve Hoelscher

True Classic

Unlike the engine, the transmission does not have a pressurized oil system with a filter so the fluid specified is non-detergent. One of the goals of detergents in oils is to keep debris suspended so that it can be filtered out. For non-detergent oils, you want the debris to fall out of suspension and stick to the bottom or walls or a magnet so that the debris doesn't circulate around ruining stuff. So often times you see a lot of nasty looking parts while the oil itself doesn't look so bad. I work on axles a lot and it is the same scenario.

Also, you could use RTV on that joint with a high degree of success. Cleanliness is important but it appears from Steve's pictures that the parts are designed to be compatible with a liquid gasket (see the chamfer?). EP additives are very surface-active and are aggressive with the RTV so make sure you use the correct oil. One advantage of the RTV joint is that there is metal-to-metal contact so the diff bearing preload will be very stable. With a paper gasket, if it creeps .001" you loose a thou of preload. Looks like Steve has a fresh tube of Ultra Black which I have used with good success (albeit in other applications).

Agreed on all points.

The transmission pictured had a couple of problems; first, it had the wrong gear oil. Which promoted the second problem. It was run very hard (in a track car) and over heated the gear oil caused excessive wear throughout the transmission. Nor was the gear oil changed regularly so it suffered from both break-down and excessive contamination from the wear. The oil came out black and heavy with contamination. The bearings, synchros, sliders, forks, gears and gear sleeves were all junk. All worn beyond serviceable limits.

The X transaxle does not have a hypoid gear so there is no need for an EP gear oil. I can almost always tell when one of these transmissions has had EP in it because of the resulting leaks.

The X case was designed for use with a gasket but work quite well with RTV only. The OE gaskets are quite thin so the diff preload is pretty sable. When I build racing transmission I never use gaskets, RTV only. The window for diff preload on a racing transmission is only a couple of thousandths. Outside of that window the bearings _will_ fail prematurely from the heat expansion. Using a gasket makes this problem worse. RTV only make the case interface more stable and reduces the change in tolerances.

I built most of the current batch of units (all for street cars) with gaskets as the shim stacks are sized for that clearance so its much easier to set them up with the standard range of shims. Also, I had a couple of people ask about the lack of gaskets. It looks more OEM with the gaskets in place. I do use RTV with the gaskets. Close examination will show a tiny bead of black RTV where the case meets the gasket.

Another word on oils. I know the factory service manual says to use GL1. I haven't used GL1 in probably 30 years, nor should you use it for any reason. As a gear oil its at least 3 generations out of date. There are several modern oils that work far better. I always recommend Redline MTL for street cars and MT90 for track/race cars. MTL/MT90 is a modern synthetic formulated to work with a synchromesh transmission. It works very well with the Porsche Type _and_ blocker ring type synchronizers as well as the various bearings. Its stable over a wide range of temperature (MT90 shifts its temp range up slightly for better high temperature performance) so it works well in your street car. It will flow better on a cold morning and not thin out excessively on those long summer drives. There are others that work reasonably well. GM, Castrol, Pennzoil all have a good synchomesh fluid (I assume that GM's synchromesh is probably one of the other two simply labeled as GM.

EP oils don't work very well with the sychronizers. And please note that there is no brass in the X1/9 transmissions. Nor do any of the "90 wt" or multi-viscosity (75/90, 80/140, etc..) gear oils. Those are primarily intended for older transmissions or differentials.

Steve Hoelscher

True Classic

Building another 4 speed with a 3.76 (Yugo) final drive. The Yugo pinion shaft isn't threaded so I have to use the shop press to install the snap ring that holds the gearset together.

Rupunzell

Bernice Loui

My opinion on oils used in these transaxles, use only the very best oil proven in real world demanding conditions. Cost of oil is minimal given the possible wear and problems due to lesser protective oils.

IMO, it makes absolutely no sense to use anything less than the very best once the consideration of rebuild cost, parts cost and scarcity of known quality OEM parts. There was a time when OEM Fiat parts were low cost and plentiful. This is no longer the case today as OEM quality parts are not low cost any more with some specific parts becoming difficult to obtain. Bottom line, do all possible to take care of these transaxles which includes using the very best oil available. This also means not bashing gears when shifting and not abusing the transaxle more than necessary.

Note on setting up the differential carrier taper bearing pre-load on the exxe transaxle. The clamping cover is often warped at the four corners where the cap screws hold down the cover. This warpage needs to be accounted for while measuring for pre-load shims. If this is not done, the measured thickness for pre-load shims can be off by a few thousands of an inch. This might not appear to be significant, the difference in taper bearing pre-load of a few thousands is HUGE in bearing pre-load. This can be the difference between long bearing life and bearing failure in short time.

My method for dealing with this is to put the taper bearing loading cover on a expanding mandrel, then chuck the assembly in a lathe. Using an accurate dial indicator adjust the cover face that contacts the taper roller bearing for a run out of less than 0.001". Then check the run out at the face of the cover flange where the four M8 cap screw holes live. It is common to discover between 0.002" to 0.005" or more difference between the area between the M8 screw holes -vs- the edge of the M8 screw hole. Check twice with the dial indicator, then face off the cover flange areas until both the flange area and surface that contacts the taper roller bearing is within 0.001". This method can also substitute for a stack of different size shims.

Do not measure the Fiat OEM spec gap with the O-ring in place, this will never work.

Bernice

IMO, it makes absolutely no sense to use anything less than the very best once the consideration of rebuild cost, parts cost and scarcity of known quality OEM parts. There was a time when OEM Fiat parts were low cost and plentiful. This is no longer the case today as OEM quality parts are not low cost any more with some specific parts becoming difficult to obtain. Bottom line, do all possible to take care of these transaxles which includes using the very best oil available. This also means not bashing gears when shifting and not abusing the transaxle more than necessary.

Note on setting up the differential carrier taper bearing pre-load on the exxe transaxle. The clamping cover is often warped at the four corners where the cap screws hold down the cover. This warpage needs to be accounted for while measuring for pre-load shims. If this is not done, the measured thickness for pre-load shims can be off by a few thousands of an inch. This might not appear to be significant, the difference in taper bearing pre-load of a few thousands is HUGE in bearing pre-load. This can be the difference between long bearing life and bearing failure in short time.

My method for dealing with this is to put the taper bearing loading cover on a expanding mandrel, then chuck the assembly in a lathe. Using an accurate dial indicator adjust the cover face that contacts the taper roller bearing for a run out of less than 0.001". Then check the run out at the face of the cover flange where the four M8 cap screw holes live. It is common to discover between 0.002" to 0.005" or more difference between the area between the M8 screw holes -vs- the edge of the M8 screw hole. Check twice with the dial indicator, then face off the cover flange areas until both the flange area and surface that contacts the taper roller bearing is within 0.001". This method can also substitute for a stack of different size shims.

Do not measure the Fiat OEM spec gap with the O-ring in place, this will never work.

Bernice

Last edited:

Rupunzell

Bernice Loui

Difficult-expensive lesson learned about using the proper and best oil for the exxe transaxle. Many decades ago (about 1980) got involved with a SCCA exxe. The exxe did not survive more than two laps before the exxe came to an abrupt stop on the track. After this exxe returned on the end of a hook, transaxle was taken apart to discover the entire set of sleeve bearings were seize on solid causing the transaxle to lock-up solid.

Oil used was generic brand gear oil specified for manual transmissions.

This was a rather expensive less learned. Or why I'm essentially militant about what oil should be used in these transaxles.

Bernice

Oil used was generic brand gear oil specified for manual transmissions.

This was a rather expensive less learned. Or why I'm essentially militant about what oil should be used in these transaxles.

Bernice

Agreed on all points.

The transmission pictured had a couple of problems; first, it had the wrong gear oil. Which promoted the second problem. It was run very hard (in a track car) and over heated the gear oil caused excessive wear throughout the transmission. Nor was the gear oil changed regularly so it suffered from both break-down and excessive contamination from the wear. The oil came out black and heavy with contamination. The bearings, synchros, sliders, forks, gears and gear sleeves were all junk. All worn beyond serviceable limits.

fiatfactory

Steve Cecchele

Steve, I would love to see a photo of the failed part. If I understand the failure you describe that is indeed a very unusual one. The side gear, pictured below is a single machined piece without an apparent weakness that would point to such a failure.

OK since my first look down inside the transmission, I think what has happened now is the side gear has somehow 'dropped' down and into the trans...

Now sure how, or if, this can be rectified without dropping the transmission and disassembly.

any thoughts?

SteveC

Steve Hoelscher

True Classic

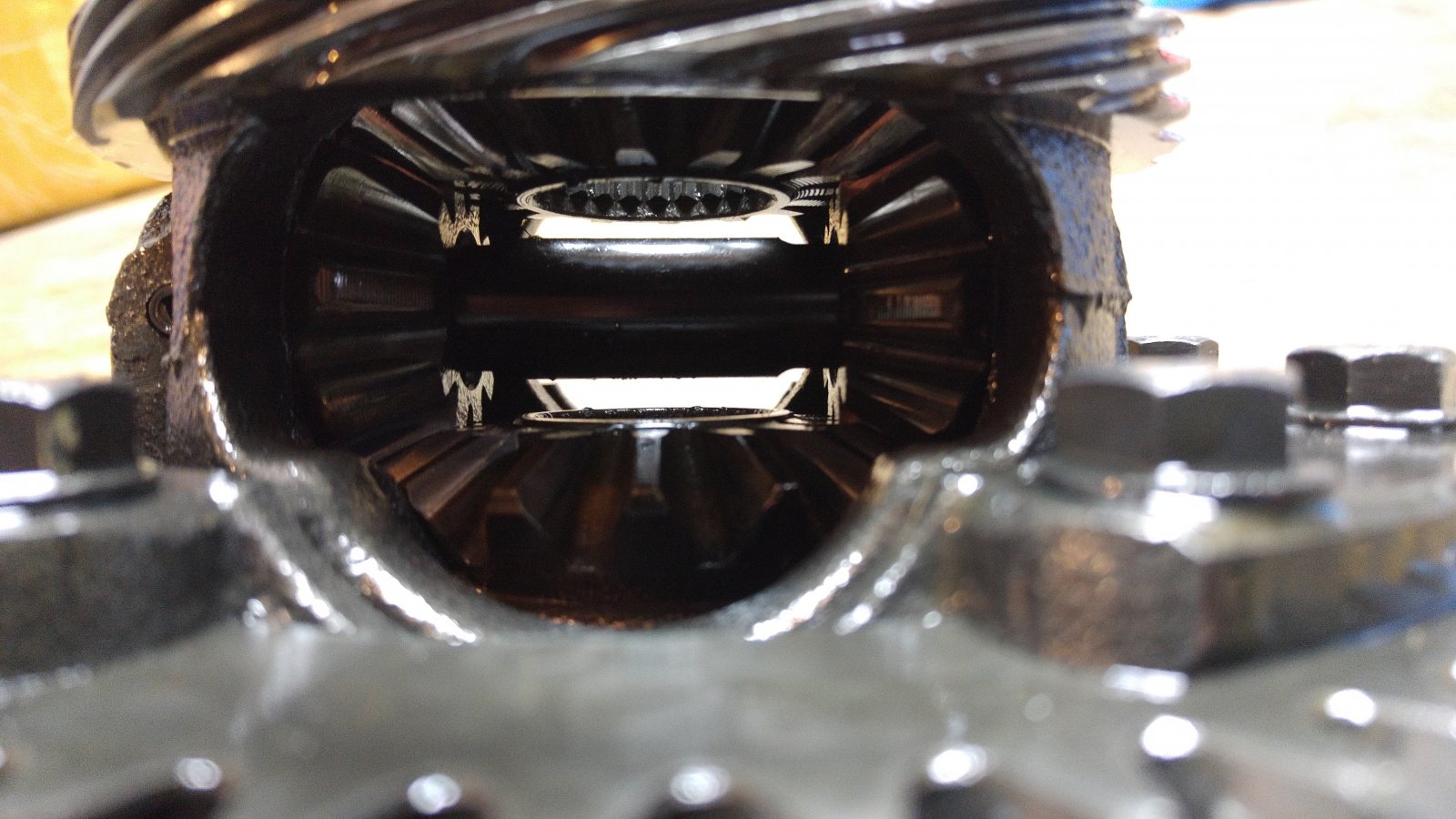

Hmmm, that is an interesting picture. The photo appears to have been taken through the axle seal, stub axle removed, viewing from the right side of the car. Correct?

First the obvious: The big shaft in the middle of the hole is the pinion shaft for the spider gears, in its normal position. In the upper right part of the opening appears to be a side gear. If so, that gear is clocked 90 degrees out of position. Looking in through the axle seal hole you should be looking through the middle of that gear and the only thing you would see is the stub axle interfacing splines on the interior of the gear. What I think I am looking at there are the teeth on the outside of the side gear. Which means the gear has rotated out of position.

The really puzzling thing is, that can't happen. If the transmission was working and the stub axle was still in place, the side gear can't move out of position like that. Its located by the stub shaft. And that shaft extends all the way through to the interior of the gear where the stub axle's snap right retains it. If you remove the axles you can rotate the pair of side gears and walk them all the way around. In fact, that's how you assemble the diff: After installing the pinion shaft and spider gears you insert a side gear and rotate it to the far side of the housing. Then insert the second side gear and then rotate them back to the axle openings.

I would assume that somebody had the axles out and while they were out the side gears got rotated. Now they won't engage the side gear's splines.

Assuming both axles are out you should be able to reach in the hole with a long screwdriver and push the side gear back toward its position. Once it blocks the axle hole you might be able to work it the rest of the way into place with a pick. Otherwise, it will have to come out and apart.

Photo of the diff internals looking from the access port: Pinion shaft/spider gears and side gears.

Pic of what the stub axle hole _should_ look like. You can see the side gear's interior splines.

First the obvious: The big shaft in the middle of the hole is the pinion shaft for the spider gears, in its normal position. In the upper right part of the opening appears to be a side gear. If so, that gear is clocked 90 degrees out of position. Looking in through the axle seal hole you should be looking through the middle of that gear and the only thing you would see is the stub axle interfacing splines on the interior of the gear. What I think I am looking at there are the teeth on the outside of the side gear. Which means the gear has rotated out of position.

The really puzzling thing is, that can't happen. If the transmission was working and the stub axle was still in place, the side gear can't move out of position like that. Its located by the stub shaft. And that shaft extends all the way through to the interior of the gear where the stub axle's snap right retains it. If you remove the axles you can rotate the pair of side gears and walk them all the way around. In fact, that's how you assemble the diff: After installing the pinion shaft and spider gears you insert a side gear and rotate it to the far side of the housing. Then insert the second side gear and then rotate them back to the axle openings.

I would assume that somebody had the axles out and while they were out the side gears got rotated. Now they won't engage the side gear's splines.

Assuming both axles are out you should be able to reach in the hole with a long screwdriver and push the side gear back toward its position. Once it blocks the axle hole you might be able to work it the rest of the way into place with a pick. Otherwise, it will have to come out and apart.

Photo of the diff internals looking from the access port: Pinion shaft/spider gears and side gears.

Pic of what the stub axle hole _should_ look like. You can see the side gear's interior splines.

Steve Hoelscher

True Classic

Bernice makes a good point about cutting corners on oil. I don't see that so much these days but its worth repeating. People don't seem to mind spending the money on quality synthetic motor oil and changing it regularly. Certainly you would make the same investment in oil for your transmission. That said, I still get into arguments with people about GL1. "That's what the factory recommends". Yeah, and Doctors used to prescribe leeches too. We know better now. As I said, technology has had great impact on modern lubricants. There are far better options than GL1. It only makes sense to take advantage of them.

And parts are getting harder to find. I bought every 3-4 slider in the US back in October when I started this round of build. And I found some OE synchros and bought all of those too. When I was last building these regularly a typical 5 speed build cost me about $350 in parts. Now its more than double that.

A note on diff bearing preload. Yes, the seal carriers can be, and usually are, warped. The 5 speed units are aluminum and almost always have the ears bent down where the bolt holes are. I have come up with my own work around for that. Also, I know lots of "professionals" who have rebuilt these transmissions that have no idea how to set the bearing preload. Or that they even need to.

Along those same lines, there are numerous things in these transmissions that require detailed inspection and measurement to determine serviceability. Most obvious is the reverse idler shafts. I often find these bent. It takes a proper straight edge to identify a bent one. Gear sleeves are often worn out. Internal linkage components often bent, or cracked. And on and on....

And parts are getting harder to find. I bought every 3-4 slider in the US back in October when I started this round of build. And I found some OE synchros and bought all of those too. When I was last building these regularly a typical 5 speed build cost me about $350 in parts. Now its more than double that.

A note on diff bearing preload. Yes, the seal carriers can be, and usually are, warped. The 5 speed units are aluminum and almost always have the ears bent down where the bolt holes are. I have come up with my own work around for that. Also, I know lots of "professionals" who have rebuilt these transmissions that have no idea how to set the bearing preload. Or that they even need to.

Along those same lines, there are numerous things in these transmissions that require detailed inspection and measurement to determine serviceability. Most obvious is the reverse idler shafts. I often find these bent. It takes a proper straight edge to identify a bent one. Gear sleeves are often worn out. Internal linkage components often bent, or cracked. And on and on....

bjwhite

True Classic

and all of this is exactly why when Steve offered to do another run of 5-speed rebuilds, I was first in line!

Broke my leg skiing last weekend so I won’t be swapping out the gearbox anytime soon (surgery then 6-8 weeks recovery) but I’m looking forward to a slick shifting X. Thanks Steve.

Broke my leg skiing last weekend so I won’t be swapping out the gearbox anytime soon (surgery then 6-8 weeks recovery) but I’m looking forward to a slick shifting X. Thanks Steve.

fiatfactory

Steve Cecchele

Hmmm, that is an interesting picture. The photo appears to have been taken through the axle seal, stub axle removed, viewing from the right side of the car. Correct?

First the obvious: The big shaft in the middle of the hole is the pinion shaft for the spider gears, in its normal position. In the upper right part of the opening appears to be a side gear. If so, that gear is clocked 90 degrees out of position. Looking in through the axle seal hole you should be looking through the middle of that gear and the only thing you would see is the stub axle interfacing splines on the interior of the gear. What I think I am looking at there are the teeth on the outside of the side gear. Which means the gear has rotated out of position.

Correct on all points.

Axle stub shaft clip came out broken in two, and axle stub shaft had partially slid out of the transmission... resulting in no drive. On disassembly and inspection this is what was found... good to know the side gear CAN be rotated around in situ... that's the next step. New C clip on the axle stub shaft (which is getting replaced with another good used one as the splines look a little worse for wear on the original) and hopefully the car is rolling again.

SteveC

Steve Hoelscher

True Classic

Correct on all points.

Axle stub shaft clip came out broken in two, and axle stub shaft had partially slid out of the transmission... resulting in no drive. On disassembly and inspection this is what was found... good to know the side gear CAN be rotated around in situ... that's the next step. New C clip on the axle stub shaft (which is getting replaced with another good used one as the splines look a little worse for wear on the original) and hopefully the car is rolling again.

SteveC

OK. That makes sense. Those clips can break but usually they foul the axle's splines and make the axle difficult to remove. You actually got lucky that it came out the way it did.

I have never tired to rotate the side gears positions when installed in a transmission. I have only done it when building a diff on the bench. In theory it could be done. I am worried about what happened to the side gear on the other side.

Let me know if you solve the problem.

Steve Hoelscher

True Classic

and all of this is exactly why when Steve offered to do another run of 5-speed rebuilds, I was first in line!

Broke my leg skiing last weekend so I won’t be swapping out the gearbox anytime soon (surgery then 6-8 weeks recovery) but I’m looking forward to a slick shifting X. Thanks Steve.

Oh, wow... sorry to hear that. Here's to your speedy recovery.

beezee

True Classic

A note on diff bearing preload. Yes, the seal carriers can be, and usually are, warped. The 5 speed units are aluminum and almost always have the ears bent down where the bolt holes are. I have come up with my own work around for that. Also, I know lots of "professionals" who have rebuilt these transmissions that have no idea how to set the bearing preload. Or that they even need to.

I am curious what your work around is for the warped seal carrier (if you wouldn't mind sharing).

Brian

Steve Hoelscher

True Classic

There are two actually; I used to measure the depth from the case's mating surface to the bearing race, then measure the height of the seal carrier from the shoulder to the mating face of the barrel. The difference, plus 2-3 thousandths, is the thickness of the required shim.

When I was at a friends machine shop one day I had an idea. I had him machine two collars, both 100/1000ths tall. One is sized to fit in the case and sit on the bearing race. The other is sized to fit over the seal carrier's barrel. Then I stack them and measure add shims until I get the required clearance. Easy peasy.

When I was at a friends machine shop one day I had an idea. I had him machine two collars, both 100/1000ths tall. One is sized to fit in the case and sit on the bearing race. The other is sized to fit over the seal carrier's barrel. Then I stack them and measure add shims until I get the required clearance. Easy peasy.