JNewm

True Classic

Hi all--

I recently replaced a failed water pump on my '81 (non-AC) X. Curious about the various offerings, I decided to order a couple of different replacement pumps to see how they stack up. These were the Beck Arnley pump + housing (from eBay) and the pump only from MWB. Some side-by-side photos, along w/ photos of the stock unit, are below.

I'd be curious to hear y'all's thoughts. My initial reactions:

(1) The Beck Arnley unit's design is much closer to stock than the MWB unit. In particular, the impeller on the Beck Arnley is basically exactly like the stock impeller. They're very thick and chunky, more like a "screw"-type impeller than a "blade"-type. As you can see, the MWB impeller is quite a bit different. It has thin blades oriented perpendicular to the water flow. I did not flow-test them (no idea how to do that and wouldn't have the equipment anyway!), but my intuition is that the blade-type MWB unit would create a lot more cavitation. It looks like it would thrash a lot more water around, but with less directional force.

(2) The Beck Arnley unit shipped at close-to-spec clearance. It was about 1.5 mm between the impeller and housing as shipped. I replaced the gasket with a thinner paper one, and that got it down to the wide end of spec (~1.3 mm). As an aside, it was really tricky to measure. I used a piece of paper w/ a 1.5mm mark folded at a right angle. I'm sure there's a better way. At any rate, 1.3mm was basically the same as the clearance on the (failed) stock-unit, which cooled the car just fine for ~40 years. So I felt pretty good about installing it at the wide end of the clearance.

(3) The MWB unit is way off in terms of clearance. There's a much bigger gap between impeller and housing. But as you can see, the impeller is also much smaller diameter. So it's hard to measure actual clearance, given that the actual clearance is more between the impeller and the cone/funnel that leads to the inlet tube... Rather than between the impeller and the flat housing wall/lip.

Anyway, without further ado, the pics:

Here's a side-by-side of the Beck Arnley unit (on the left) and the MWB pump mated to the stock housing.

You can really see the clearance difference.

Here's a close-up of the MWB unit mated to the stock housing. Note the impeller design and diameter.

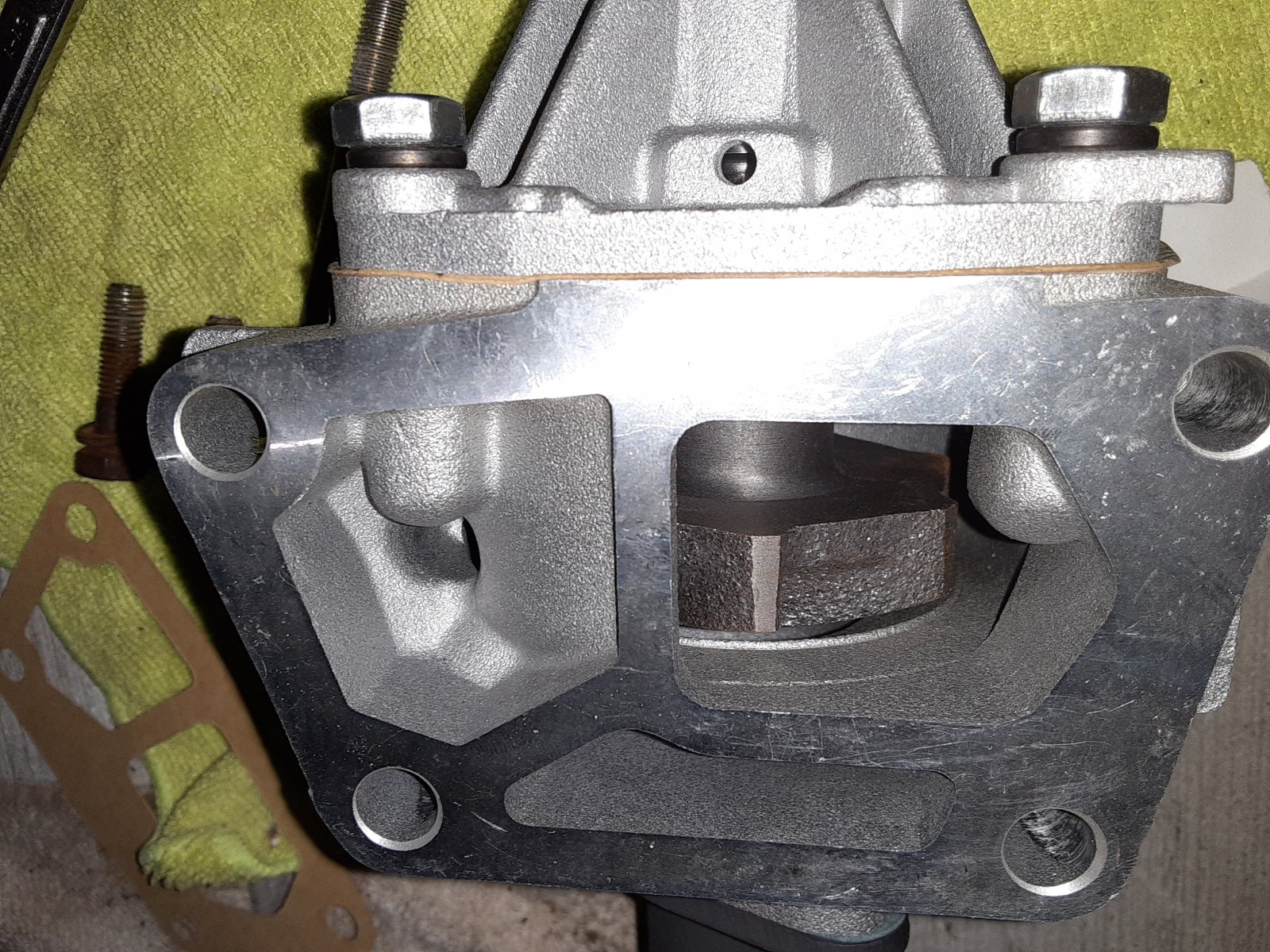

And here's a close-up of the Beck Arnley unit.

Here's the (failed) stock pump, on the right obviously. On the left is the BA unit. Note that the impeller design is much more similar. Both are screw-type.

Just b/c I was proud of how nice everything looked, here's the BA unit w/ reconditioned tube. Sanded down, rust-converter, high-temp exhaust paint.

And here's something NOT to try. As I was about to reinstall everything, I thought to myself, "This is an insane design. This inlet tube passes right by the exhaust manifold! It's like one of those inline water heaters people install in RVs to take hot showers!! Think how much better the whole system will cool if it's insulated!"

Unfortunately, there is basically ZERO clearance between this tube and the exhaust downpipe. This header wrap (double-wrapped) was enough to prevent proper mounting of the pump. So I had to take everything back off, remove the wrap, then install. If you wanted to get fancy, you could wrap it so that it just has a small gap for the pipe, but that would defeat at least some of the purpose--you'd be leaving the hottest area exposed. I consoled myself with the fact that the water only passes through this screaming hot little tube for a fraction of a second.

Moral of that story: don't try to outsmart Lampredi.

At any rate, hope this is interesting/useful to others down the road!

I recently replaced a failed water pump on my '81 (non-AC) X. Curious about the various offerings, I decided to order a couple of different replacement pumps to see how they stack up. These were the Beck Arnley pump + housing (from eBay) and the pump only from MWB. Some side-by-side photos, along w/ photos of the stock unit, are below.

I'd be curious to hear y'all's thoughts. My initial reactions:

(1) The Beck Arnley unit's design is much closer to stock than the MWB unit. In particular, the impeller on the Beck Arnley is basically exactly like the stock impeller. They're very thick and chunky, more like a "screw"-type impeller than a "blade"-type. As you can see, the MWB impeller is quite a bit different. It has thin blades oriented perpendicular to the water flow. I did not flow-test them (no idea how to do that and wouldn't have the equipment anyway!), but my intuition is that the blade-type MWB unit would create a lot more cavitation. It looks like it would thrash a lot more water around, but with less directional force.

(2) The Beck Arnley unit shipped at close-to-spec clearance. It was about 1.5 mm between the impeller and housing as shipped. I replaced the gasket with a thinner paper one, and that got it down to the wide end of spec (~1.3 mm). As an aside, it was really tricky to measure. I used a piece of paper w/ a 1.5mm mark folded at a right angle. I'm sure there's a better way. At any rate, 1.3mm was basically the same as the clearance on the (failed) stock-unit, which cooled the car just fine for ~40 years. So I felt pretty good about installing it at the wide end of the clearance.

(3) The MWB unit is way off in terms of clearance. There's a much bigger gap between impeller and housing. But as you can see, the impeller is also much smaller diameter. So it's hard to measure actual clearance, given that the actual clearance is more between the impeller and the cone/funnel that leads to the inlet tube... Rather than between the impeller and the flat housing wall/lip.

Anyway, without further ado, the pics:

Here's a side-by-side of the Beck Arnley unit (on the left) and the MWB pump mated to the stock housing.

You can really see the clearance difference.

Here's a close-up of the MWB unit mated to the stock housing. Note the impeller design and diameter.

And here's a close-up of the Beck Arnley unit.

Here's the (failed) stock pump, on the right obviously. On the left is the BA unit. Note that the impeller design is much more similar. Both are screw-type.

Just b/c I was proud of how nice everything looked, here's the BA unit w/ reconditioned tube. Sanded down, rust-converter, high-temp exhaust paint.

And here's something NOT to try. As I was about to reinstall everything, I thought to myself, "This is an insane design. This inlet tube passes right by the exhaust manifold! It's like one of those inline water heaters people install in RVs to take hot showers!! Think how much better the whole system will cool if it's insulated!"

Unfortunately, there is basically ZERO clearance between this tube and the exhaust downpipe. This header wrap (double-wrapped) was enough to prevent proper mounting of the pump. So I had to take everything back off, remove the wrap, then install. If you wanted to get fancy, you could wrap it so that it just has a small gap for the pipe, but that would defeat at least some of the purpose--you'd be leaving the hottest area exposed. I consoled myself with the fact that the water only passes through this screaming hot little tube for a fraction of a second.

Moral of that story: don't try to outsmart Lampredi.

At any rate, hope this is interesting/useful to others down the road!