jvandyke

True Classic

Recent clutch R&R left pedal feeling crappy.

Doesn't start to resist (engage master) until over halfway down.

Much bleeding but a one-man job with a stick. Will try extensive bleeding tonight with helper.

Just wondering if that is a symptom of air:

no clutch action until pedal well past half, then decent movement of slave (about one inch).

Car is drivable but pedal sometimes doesn't want to come up again.

Last night I pumped and held (with a stick) and cracked output at master, banjo and slave bleeder and only got a couple really small bubbles after about 10oz of juice moving through.

Just wondering if bleeding is the issue or if I have a master not happy (it's pretty new as is slave).

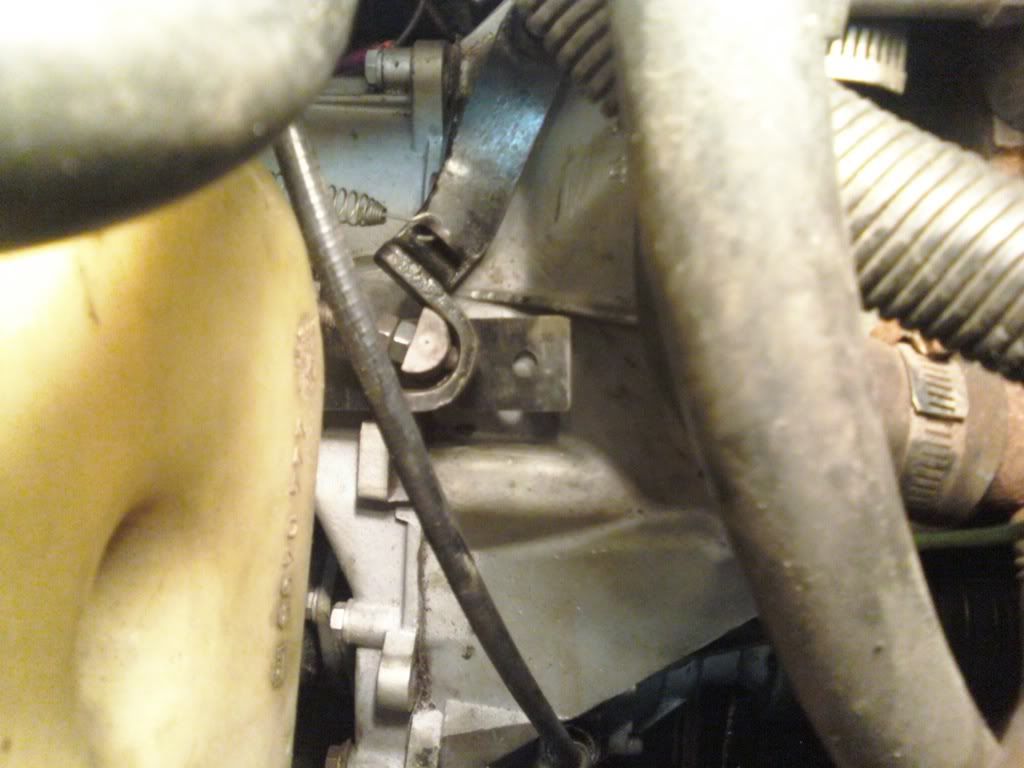

I can watch the rod on the master going in with pedal movement but there's no resistance until about half way down, then "fair" clutch action.

I was running a pedal stop before I tore into it, now I can't or I don't decent disengagement. I did not disturb hydraulics other than a quick test for bleeding before I started, which may have been enough to make it grumpy. Maybe I need to rig up a pressure bleeder. Be nice to find a generic reservoir cap that fits, I remember I found a weed killer bottle cap fit my old Opel nicely.

Doesn't start to resist (engage master) until over halfway down.

Much bleeding but a one-man job with a stick. Will try extensive bleeding tonight with helper.

Just wondering if that is a symptom of air:

no clutch action until pedal well past half, then decent movement of slave (about one inch).

Car is drivable but pedal sometimes doesn't want to come up again.

Last night I pumped and held (with a stick) and cracked output at master, banjo and slave bleeder and only got a couple really small bubbles after about 10oz of juice moving through.

Just wondering if bleeding is the issue or if I have a master not happy (it's pretty new as is slave).

I can watch the rod on the master going in with pedal movement but there's no resistance until about half way down, then "fair" clutch action.

I was running a pedal stop before I tore into it, now I can't or I don't decent disengagement. I did not disturb hydraulics other than a quick test for bleeding before I started, which may have been enough to make it grumpy. Maybe I need to rig up a pressure bleeder. Be nice to find a generic reservoir cap that fits, I remember I found a weed killer bottle cap fit my old Opel nicely.

Last edited: