Stuartc

True Classic

I’m at the starting point of my restoration project but I was becoming annoyed opening and latching the Frunk lid numerous times a day so I’m now part of the gas strut club!

Best description of my attempt is “Same, same but different”!

I have used an eyelet setup at top of the hinge primarily so that when the lid is down there was no interference with the “Frunk” light. I’ve manipulated the metal bracket so that it follows the curve of the Frunk hinge and bolted using m5 bolts. Top eyelets are bolted using m6 shoulder bolts. I decided on this setup as it keeps all the struts fixings central to the plane of the hinge thus keeping clear of the top if stored and Frunk light as previously mentioned.

I have used an eyelet setup at top of the hinge primarily so that when the lid is down there was no interference with the “Frunk” light. I’ve manipulated the metal bracket so that it follows the curve of the Frunk hinge and bolted using m5 bolts. Top eyelets are bolted using m6 shoulder bolts. I decided on this setup as it keeps all the struts fixings central to the plane of the hinge thus keeping clear of the top if stored and Frunk light as previously mentioned.

Lid pretty much holds just below screen hight as this is at the point of “over centre” so below this lid just closes normally and above the lid automatically raises to its max opening.

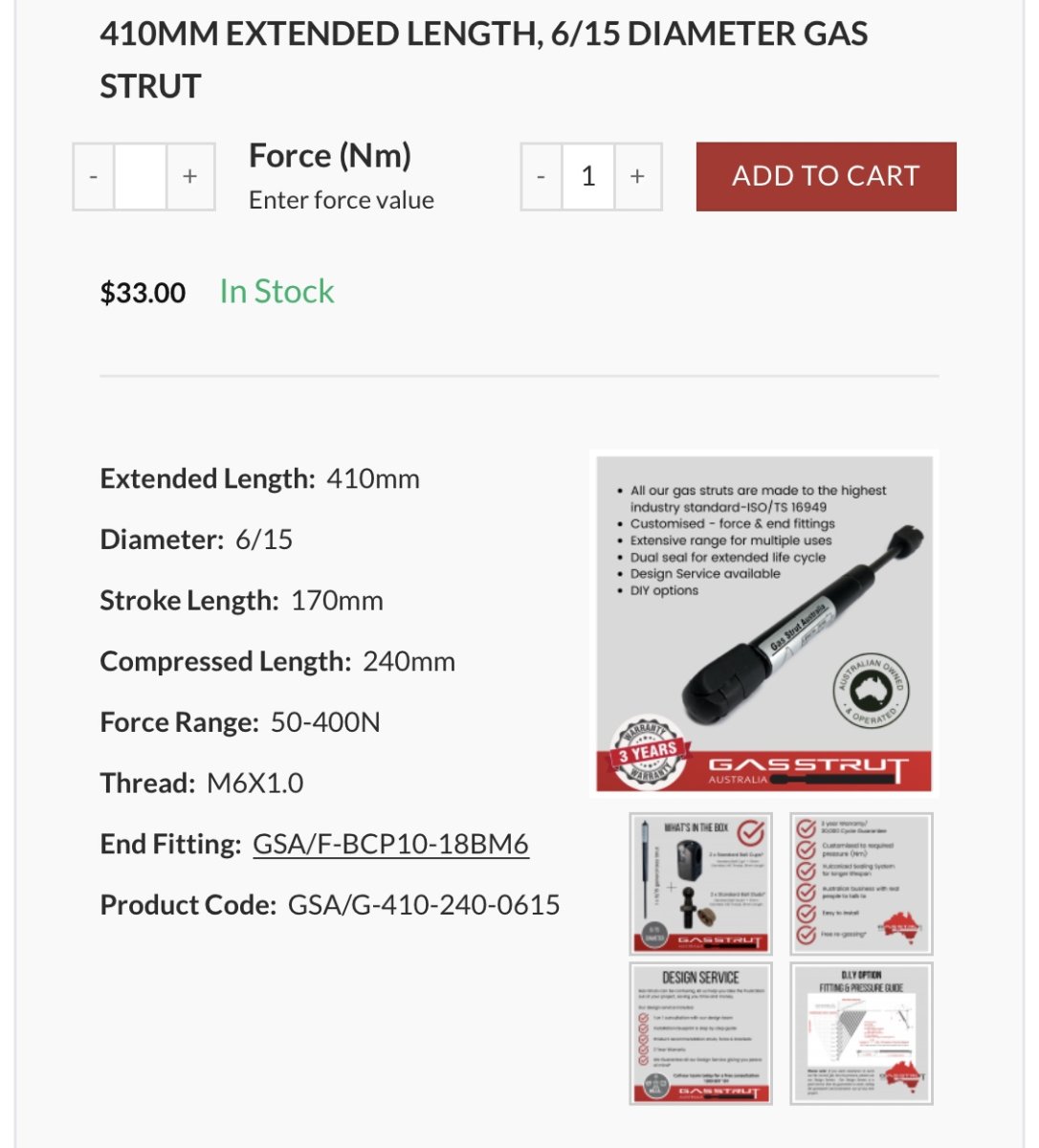

Struts are as follows

Struts are set to 160NM force which appears to be the sweet spot

Best description of my attempt is “Same, same but different”!

Lid pretty much holds just below screen hight as this is at the point of “over centre” so below this lid just closes normally and above the lid automatically raises to its max opening.

Struts are as follows

Struts are set to 160NM force which appears to be the sweet spot

Last edited: