You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is this crank position sensor bracket original?

- Thread starter Jonohhh

- Start date

Bjorn Nilson

True Classic

Shortly after buying my UT Mk1 engine I decided to remove the old crappy Digiplex system, AFM, ignition etc. and go for a modern after market ECU. The only drawback was the necessary upgrade of most of the engine electronics (such as the crank sensor) but it was definitely worth it. The engine is still a classic Lampredi but so much easier to tune/service and it is RELIABLE.

When time comes I will definitely do the same with my 128SL 1300. No more carbs etc for me.

When time comes I will definitely do the same with my 128SL 1300. No more carbs etc for me.

Jonohhh

True Classic

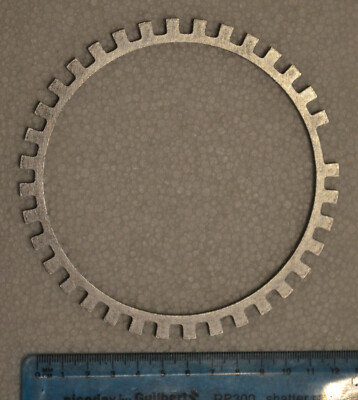

I was going to suggest it's possible that it has a 2 tooth crank position sensor, which isn't particularly good but is usable.Perfect thanks. So this is TDC sensor with a two teeth (correction from the initial post). The offset from the TDC mark on the pulley relates to the tooth relative to the sensor placement. In the original pic I now see there are two teeth across from each other (one can just see the little nubs).

Why the two teeth, showing my ignorance or inability to parse the why…

A bunch of different details on this engine the more one looks. (Hanger engine mount instead of snail for example)

Thank you very much.

However, I've then found some Fiat documentation showing that a 50+ tooth flywheel trigger is also used.

To complicate matters more, there is also a "distributor" looking thing used on some

Last edited:

Jonohhh

True Classic

That's the exact part I'm talking about. For people going standalone, that seems like the cleanest way to get away from wasted spark and improve injection timing.is this what you mean for the distributor adaptor this is a picture of a punto gt

Thanks! I misremembered the application!

kmead

Old enough to know better

Wasted spark isn’t much of a big deal and a crank wheel is going to get you a very accurate delivery. Getting to sequential injection is great but can be done pretty easily with a sensor on the cam wheel. The distributor trigger is just another error in the process as it is at the end of the variation of the cam belt and the lash of the oil pump gear. You also need an injection system which can provide sequential (mega vs Microsquirt for example).That's the exact part I'm talking about. For people going standalone, that seems like the cleanest way to get away from wasted spark and improve injection timing.

Thanks! I misremembered the application!

I would much rather do single magnet or tooth on a the cam wheel with a Hall sensor if you are just looking for cycle lock. Adding a feature to an adjustable cam wheel or even to the pressed steel one would be pretty trivial relatively speaking.

Jonohhh

True Classic

Wasted spark isn’t much of a big deal and a crank wheel is going to get you a very accurate delivery. Getting to sequential injection is great but can be done pretty easily with a sensor on the cam wheel. The distributor trigger is just another error in the process as it is at the end of the variation of the cam belt and the lash of the oil pump gear. You also need an injection system which can provide sequential (mega vs Microsquirt for example).

I would much rather do single magnet or tooth on a the cam wheel with a Hall sensor if you are just looking for cycle lock. Adding a feature to an adjustable cam wheel or even to the pressed steel one would be pretty trivial relatively speaking.

I guess it wouldn't be too difficult to modify the timing cover back plate and install a sensor- or maybe come to some solution at the end of the camshaft.

I haven't started looking into options yet because going standalone is far in the future for me, but I'm glad to see I can stop scrounging for the application of the distributor adapter shown above. I was curious what injection system is used on cars with that sensor but now I see.

And yeah- wasted spark isn't the issue as much as batch fire injection is. It's not terrible either way but... sequential is much nicer, especially for those looking to run e85. Maybe one day...I redid all of the hoses and pump with e85 compatible ones for a reason, just in case.

Dr.Jeff

True Classic

When I was developing my standalone ECU plans I also considered that distributor style "phaser" trigger unit, in lieu of a cam sensor. My thought was it is an existing factory part so it's a direct fit simple solution. But I decided against it for a few reasons. First was what @kmead said in post #27; "The distributor trigger is just another error in the process as it is at the end of the variation of the cam belt and the lash of the oil pump gear". Second I saw a good example of how another member added a aftermarket sensor and magnet to the cam drive pulley that seemed easy enough to do. Third I found those phasers are not easy to get - especially not in good working condition. And when you do they're more costly than the one described in my "second" statement. Fourth, and perhaps most importantly, I learned that for anything less than a full-blown race engine there really is no reason to have a cam sensor at all.

The only advantage of having a cam position sensor is to go full sequential. But that will only get you a fractional improvement over other options (more on that in a minute). And even then, only if you spend a lot of time on a dyno with some very sophisticated equipment to get the sequential tuned exactly. For our SOHC engines it will not pay off; there just isn't enough potential in them to warrant full sequential. And you will never see the difference if it is for a street car.

As for the other options mentioned earlier. Most aftermarket ECUs offer what's called "semi-sequential" fuel and spark delivery. It is a bit of a combination of both batch and sequential. For engines like the SOHC where cylinders are "paired" or "siamesed" (two or more move on the same stroke and timed together), semi-sequential injects fuel and spark only in paired batches (for the paired cylinders), while the other non-paired cylinders are sequentially timed. This offers most of the benefits of a full sequential but does not require a cam position sensor. Even the MicroSquirt model offers this for a four cylinder engine.

The only advantage of having a cam position sensor is to go full sequential. But that will only get you a fractional improvement over other options (more on that in a minute). And even then, only if you spend a lot of time on a dyno with some very sophisticated equipment to get the sequential tuned exactly. For our SOHC engines it will not pay off; there just isn't enough potential in them to warrant full sequential. And you will never see the difference if it is for a street car.

As for the other options mentioned earlier. Most aftermarket ECUs offer what's called "semi-sequential" fuel and spark delivery. It is a bit of a combination of both batch and sequential. For engines like the SOHC where cylinders are "paired" or "siamesed" (two or more move on the same stroke and timed together), semi-sequential injects fuel and spark only in paired batches (for the paired cylinders), while the other non-paired cylinders are sequentially timed. This offers most of the benefits of a full sequential but does not require a cam position sensor. Even the MicroSquirt model offers this for a four cylinder engine.

Last edited:

fiatfactory

Steve Cecchele

Except Electromotive are out of business... covid shut them down and they never opened up again. I spoke to the Australian distributor just a couple of weeks ago and was told they can no longer supply control units or parts,

Electromotive's own website has a banner across the top of the page that says;

"At this point in time, Electromotive is not selling or repairing products. EMI is seeking new business partners. Thank you for your understanding and support."

but yeah a 60-2 trigger wheel gives good resolution.

SteveC

Electromotive's own website has a banner across the top of the page that says;

"At this point in time, Electromotive is not selling or repairing products. EMI is seeking new business partners. Thank you for your understanding and support."

but yeah a 60-2 trigger wheel gives good resolution.

SteveC

Stuartc

True Classic

So the Ford wheel in the pic is a direct fit to the Fiat SOHC engine?I used the trigger wheel off of a 90s ford escort (and the EDIS controller) on 2 builds so far. Welded the sensor to the bracket discussed in this thread.

View attachment 80174View attachment 80175

davejake

3 is company too!

Almost a direct fit. We put the stock pulley on a lathe and just took it down a couple mil, and pushed it on!So the Ford wheel in the pic is a direct fit to the Fiat SOHC engine?

Stuartc

True Classic

Thanks for thatAlmost a direct fit. We put the stock pulley on a lathe and just took it down a couple mil, and pushed it on!

Any chance you have a part number or model/engine it associated with as all the ones I’m coming across are for serpentine belts not v-belts?

fiatfactory

Steve Cecchele

I think he means he took the stock Fiat V belt pulley, machined that down a few mm on the outside edge, and pushed the ford steel trigger wheel in place, though I could be reading that wrong...Thanks for that

Any chance you have a part number or model/engine it associated with as all the ones I’m coming across are for serpentine belts not v-belts?

you want to search for "ring gear style 36-1 trigger wheel' and you'll find what you want... like this

Universal Trigger Wheel - 36-1 127mm OD, 108mm ID Megasquirt, DTA | eBay

4mm thick steel trigger wheel OD 127, ID 108 36-1 teeth. Can be easily welded, drilled and bolted to mount on to pulley or wherever required on the engine.

www.ebay.co.uk

or this

Ring gear style trigger wheel

Ring gear style trigger wheel - From 4.5" up to 10.25" diameter

trigger-wheels.com

SteveC

Last edited:

Dr.Jeff

True Classic

I also use the Ford trigger wheel and pick up trigger, but not the Ford ignition controller....I have the aftermarket ECU handle that. I like that the Ford wheel and sensor were designed to work together and engineered for a production vehicle application. Therefore it is extremely reliable and dependable. And the parts are readily available for very little money.

There are a couple of different Ford wheels. One can fit the non-AC Fiat pulley pretty well (as described above), and another one can fit the smaller AC Fiat pulley. But neither is a direct fit. The stock Fiat pulley needs some minor machining and you need to secure the wheel to the pulley somehow. I chose to bolt mine together rather than weld it or rely on a press fit.

I gave some detail on this for the AC pulley previously: https://xwebforums.com/forum/index.php?threads/efi-reluctor-engineering-advice-sought.35612/

There are a couple of different Ford wheels. One can fit the non-AC Fiat pulley pretty well (as described above), and another one can fit the smaller AC Fiat pulley. But neither is a direct fit. The stock Fiat pulley needs some minor machining and you need to secure the wheel to the pulley somehow. I chose to bolt mine together rather than weld it or rely on a press fit.

I gave some detail on this for the AC pulley previously: https://xwebforums.com/forum/index.php?threads/efi-reluctor-engineering-advice-sought.35612/