Fixed it!

First I checked the ECT (cold, 70ºF) - 2160 ohms at the sensor

at the ECU : 2180 ohms

Normal OP temp 263 ohms. Values within normal range according to Datsun chart

I could swap it out for a Volvo one - & make it fatter when cold.... Might need to do that depending on how the cold starts are now.

Anyway, after that I went back to thinking about what could cause the hunting. I realized that when I did the TPS trigger signal, I didn't confirm that the relay I added had diode protection to prevent interference with the stock circuitry. I simply added a diode inline from the TPS to the relay to test the operation.

With that in place, the hunting at 2.5K went away. So that aspect was resolved (YAY!). The system still runs lean though. I don't know if all the cleaning out of coking in the TB & clearing other passages has made it leaner. I certainly didn't feel the lean running condition before I started all the mods. I looked at the AFM adjustment, and that made no meaningful difference.

Manifold vacuum at idle is good.

Regulated Fuel pressure is good

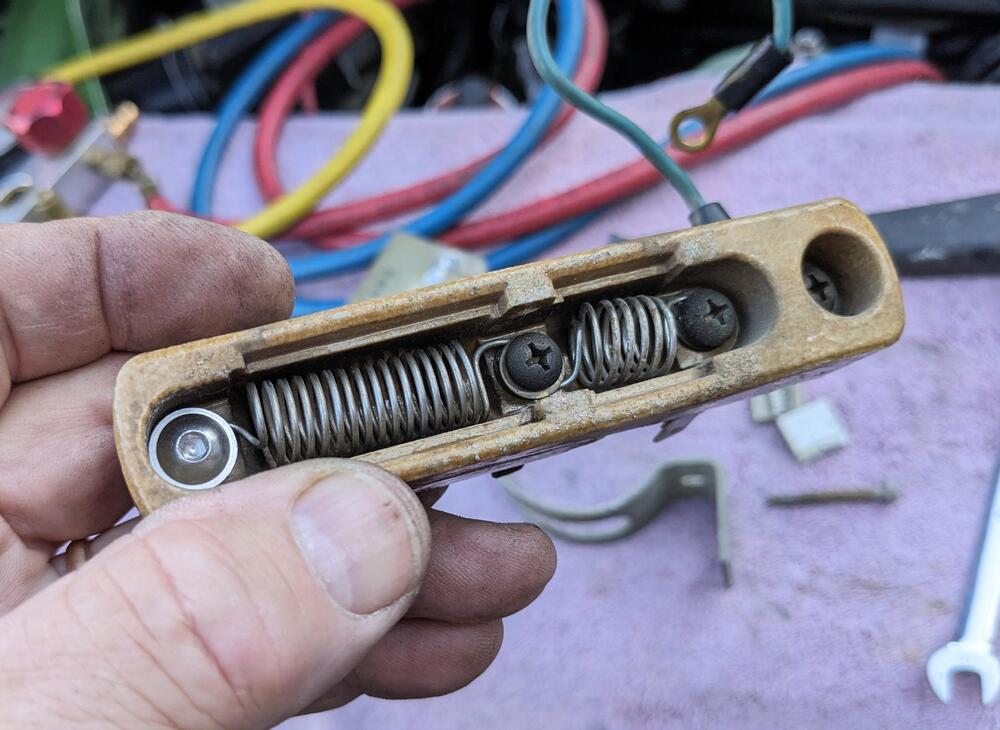

While I cogitated on how to address this, I added the AC switch plate

and added carpet mat stays

So, I decided that instead of futzing with the AFM to try & tweak the AFR's 2 whole points richer, I decided to just raise the regulated pressure to 3bar - using a Volvo regulator of course

As you can see form the video above, that brought the AFR's right where they need to be.

new regulated fuel pressure under vacuum. Rises to 3bar with vacuum removed.

Having confirmed the pressure is consistent & vacuum works I installed a nylon feed line & quick connect in the intake. Old FPR location is bridged with new hose above it.

Bay

Now I know the system is fully operational, I will revise the return setup, it is overly long - didn't want to cut down the hose that had to connect to the rail return until I knew it would work.