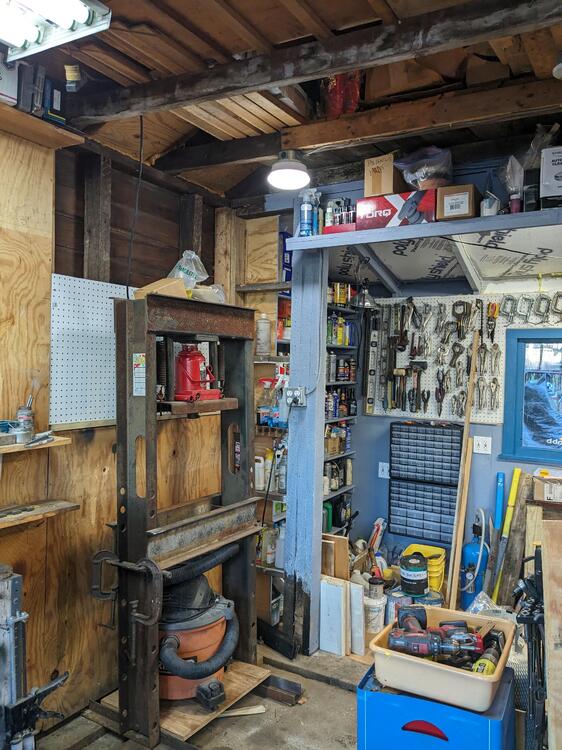

Slow going today. I had to start hanging tools & moving chemicals, I just had no floor space to move around in. I wanted to get the press moved into the main floor, and I did eventually, however I had to juggle a whole bunch of crap to make the space, just to be able to maneuver it.

I got side tracked figuring out the storage bin ideas for all the small stuff current dispersed in individual plastic trays in multiple locations. I bought 2 containers to try - and decided that instead of wasting shelf space it made more sense to suspend them on the West wall, where I was vacillating on adding additional shelves in line with the ones I already added. The conundrum for me was that the shelves would not be the same height on either side of the window, and that would bug the crap out of me DTR.

Put a bunch of M3, M4, M5 & M6 riv-nuts, and screws of different types (counter sunk, pan head Phillips and Allen in rows from L-R. That calmed me down a bit

View attachment 81818

View attachment 81818

I've ordered another matching pair to put on the other side of the window. I will make sure the spacing and offset matches

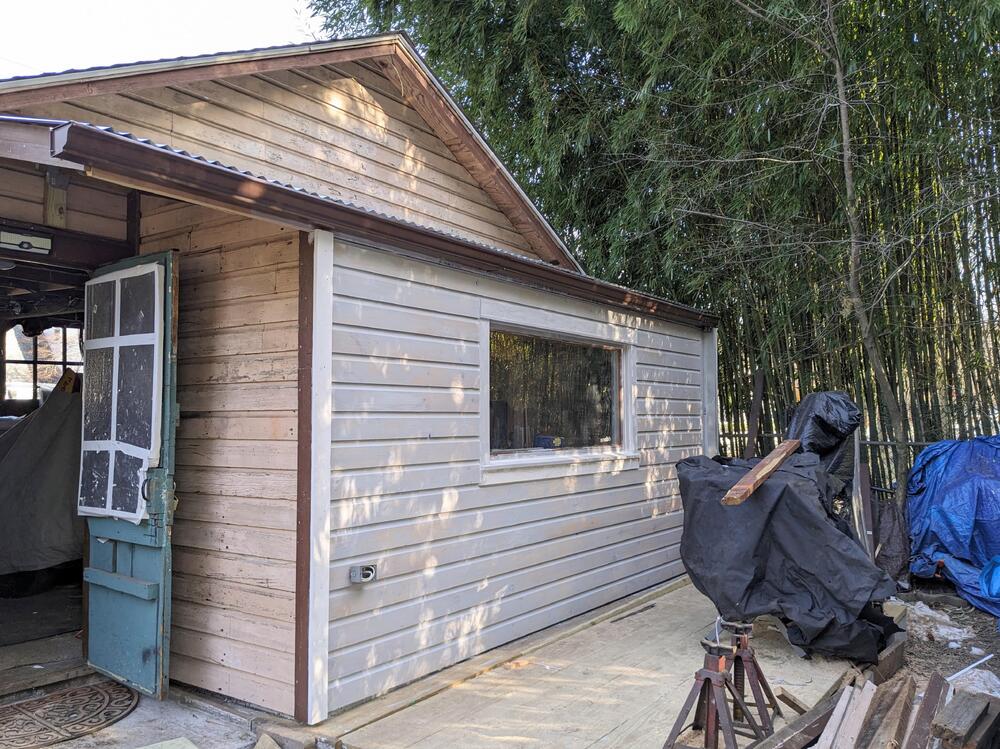

View attachment 81817

View attachment 81817

Chemicals and tools I had moved earlier in the day. Probably not their final testing place. These were all hanging on nails in the old West wall, along with about 15 pairs of pliers that I need to find the correct pegboard holder for. Many of these hangers are too long - it was cheaper to buy 100 6" than 3". I'll just cut down the ones that need to be shorter.

Finally clearing the shelves where the press needs to go

Cut the shelving, cleaned up the area, moved & levelled the press

After that I wrapped up with top coat on the west & north wall of the area

Feeling better now about how the day went by.