Started clearing the back wall yesterday. The enclosed awning will definitely make life easier, I will move the benches & tool box back there, which adds about 5' behind the Fiat. That will be enough to have the Datsun or even the pickup truck inside & be able to work on it in the dead of winter.

I found out from the meeting with one of the town building inspectors that I would be most unlikely to get approval for an additional structure of the size I wanted added to the existing garage, due to both current zoning codes and the fact that I'm in a hamlet, which apparently means any plans have top go before an architectural review board, not just the building inspectors. Reviewing my property survey, he intimated that would be a significant issue, given all the variances that would have to be factored. Apparently even a shed over 12x12' has to have a permit in our town. However, he told me that what doesn't need any kind of permit is a 'patio'. Basically, I can have a slab off the garage, just has to be 10' from the side & back. I can easily add a 16x18 concrete pad without it sticking out more than about 6' from the existing side of the garage facing the house. I'd rather have an enclosed space, but a pad would still work for me.

View attachment 81257

View attachment 81258

View attachment 81259

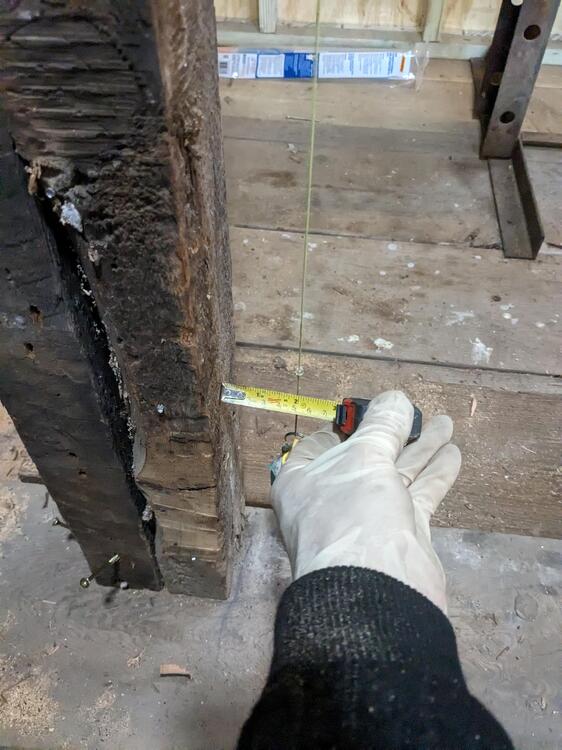

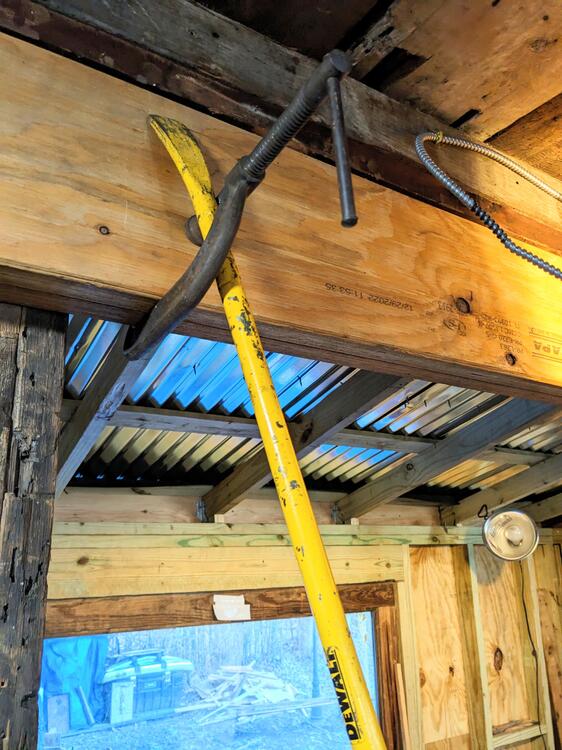

Started framing the enclosure yesterday also - the end wall is approx 14'. Add the first top plate with the rafters cut with 'birdsmouths', or chocks on the ones that didn't align well enough.

View attachment 81260

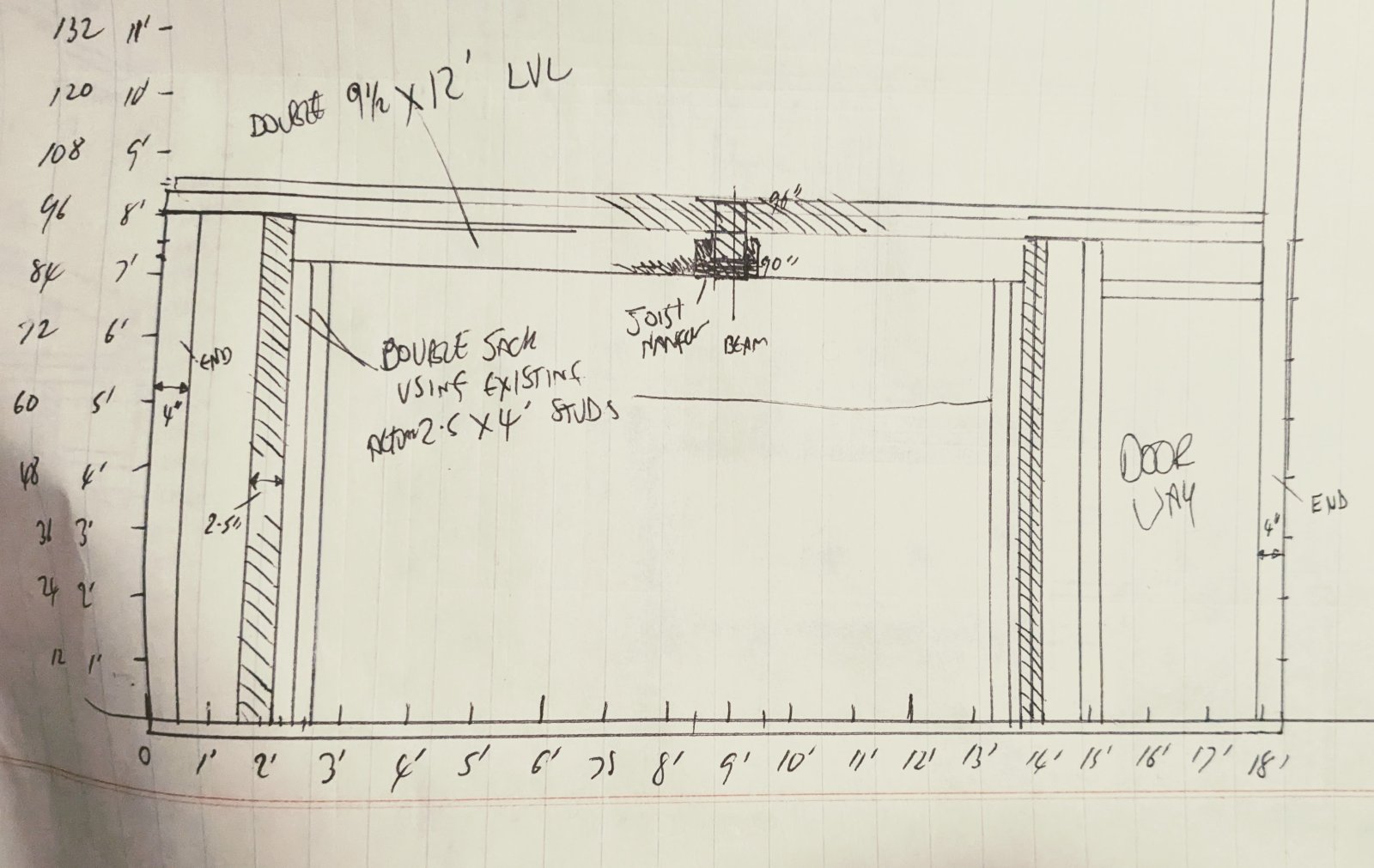

Today I added the 2nd top plate & started placing the studs 16" OC across the span. Had to make drawings to figure out the lumber & the placement of the large fixed window that I will move from the existing back wall. Calculating the cut lengths needed from the lumber lengths available is always a challenge for me, so this at least helps me mostly get it close. The window is actually 75x36. I also found my local lumber yard (vs. the box store) had the period correct 1x6 'clapboard/ lap siding' that matches the existing siding. It's now called Novelty Siding. Hopefully I'll finish the framing & sheath the walls tomorrow, and maybe get some of the siding up. The short end wall I will side with cut pieces from the old wall, there is enough length to cut off the 54" length I need for that. That will also help make it look more original from the street, since that's the only part that is really visible without entering my yard.

View attachment 81261

View attachment 81262