You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

128 SL Coupe Project

- Thread starter 128kid

- Start date

128kid

Courtney Waters

Is it true that the Velocity channel has asked you to do a series for them....no drama...no fake deadlines.....just us poor souls watching you do this work with rapt attention and our wives just shaking their heads and going back to check their facebook pages.

And here I was excited about filling in the bumper holes on my Bertone with fiberglass.

Ah, wouldn't that be awesome! But alas, no, I'll have to keep on doing it for the love of all things wheeled and Italian. Pretty sure filling holes with fiberglass is making more progress than I am this week

128kid

Courtney Waters

Dammit, now look Courtney, I don't know how bad your Redbull addiction is and all I can say is that there can be good quality of life after getting off the stuff. But I'll buy you a freakin' months supply (within reason mind you) if you shoot this work in video form and share it with us well meaning enablers!

You noticed... dang, I thought I had that under control...

I have actually cut way back on the Red Bull since this work was performed. Limited to recreational use now... Expect to see more coffee cups in future photos! Heh. The caffiene balance must be carefully maintained!

It would be fun to video this stuff but my video editing skills are nil, and my shop is currently so full it would be hard to find a place for a tripod.

Pete Whitstone

True Classic

How did I miss this thread this whole time? Damn fine work, Courtney, I am very impressed. You have some great tools in your workshop, by the looks of it. But they are only hunks of metal if you don't know how to use them. It definitely appears you have that talent. Congratulations!

Pete

Pete

motoTrooper

True Classic

my shop is currently so full it would be hard to find a place for a tripod.

Answer: Drone programmed to fly silently over your shoulder!

128kid

Courtney Waters

How did I miss this thread this whole time? Damn fine work, Courtney, I am very impressed. You have some great tools in your workshop, by the looks of it. But they are only hunks of metal if you don't know how to use them. It definitely appears you have that talent. Congratulations!

Pete

Thanks, Pete! The tool collection represents quite a few paychecks in the years since graduating college, and the skill set is simply many hours logged in the shop in through college and beyond, and reading/asking how to do things. I'm always looking to add to the shop but for the most part I've finally feel mostly self-sufficient for sheet metal, welding, and machining projects. The great part about this kind of sheet metal work is it really doesn't require many specialty tools. Exterior body panels is another thing. I'm still working up to that level... in both equipment and skills!

motoT: Hmm, yes, I've seen those... that would be amazing.

128kid

Courtney Waters

Doubler Fabrication

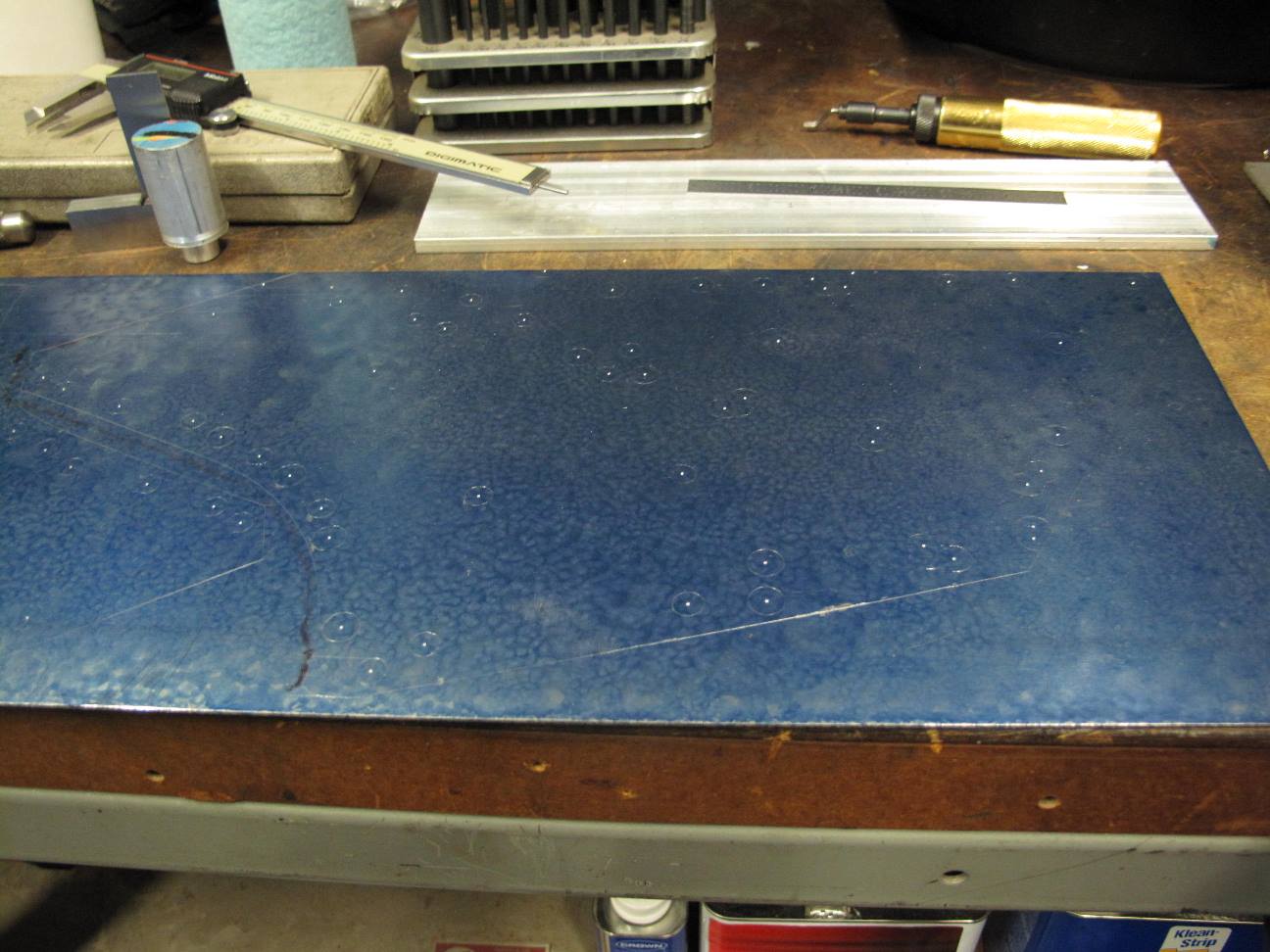

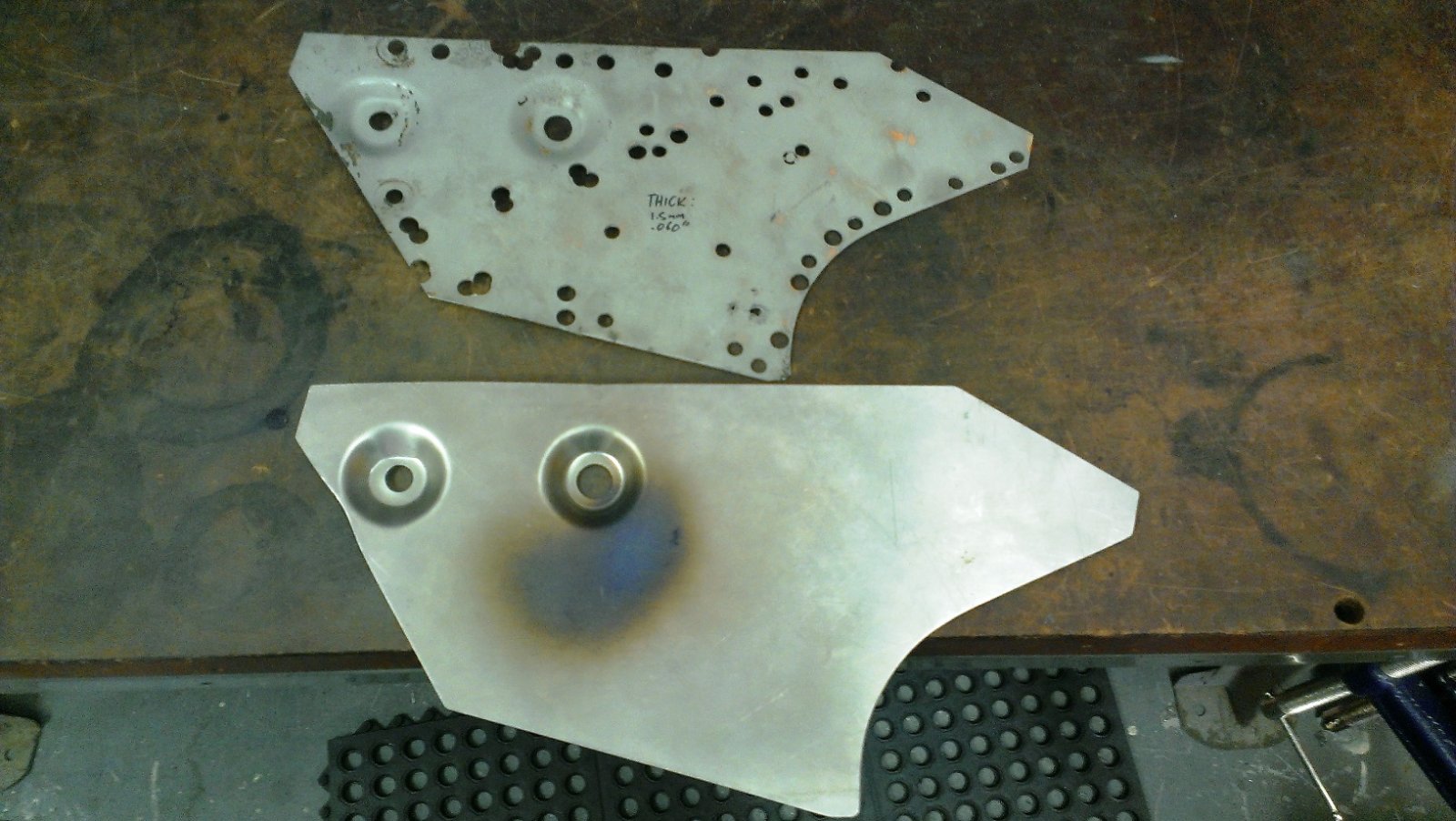

Part made from 1.5mm (16 GA) sheet.

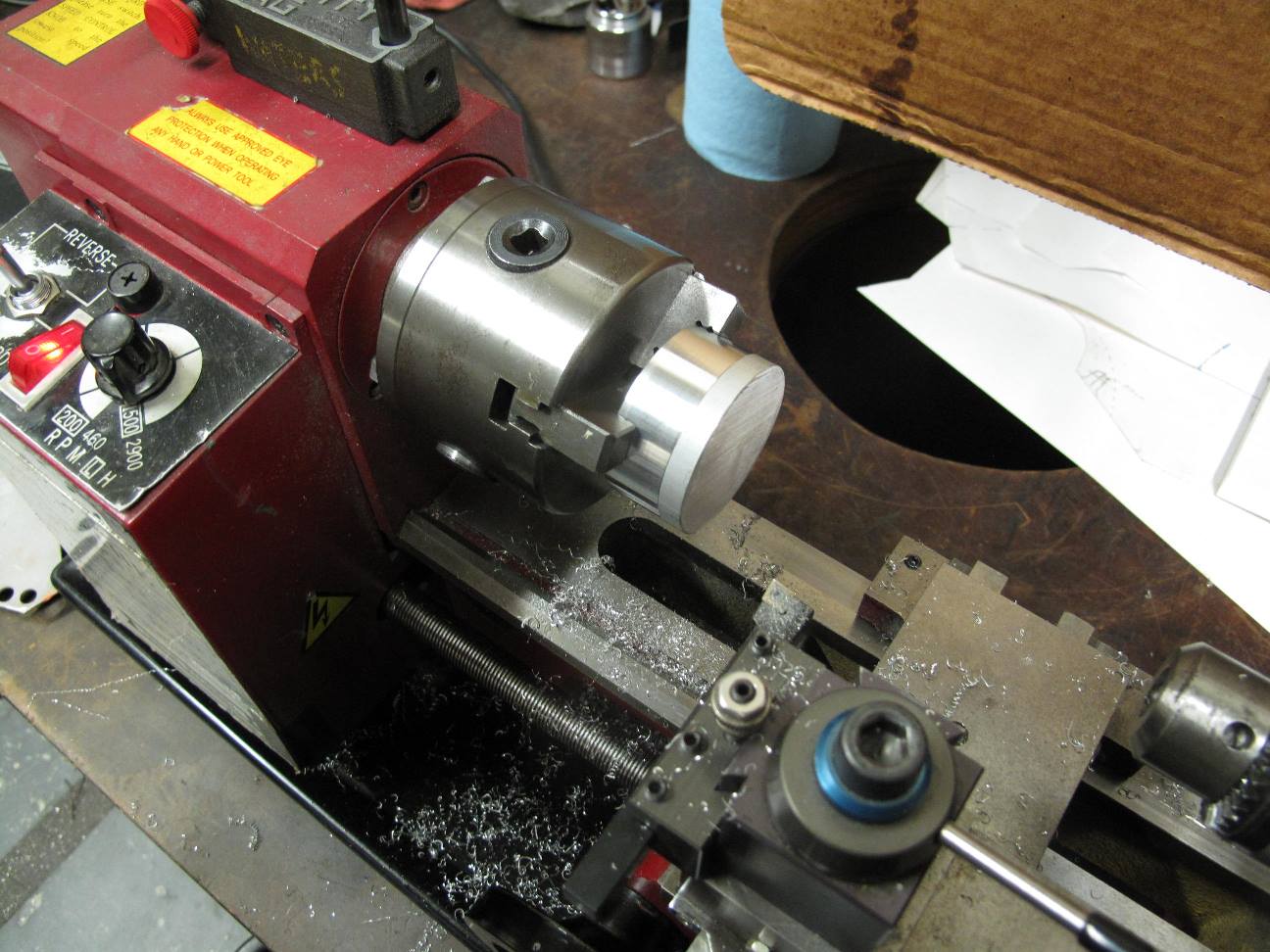

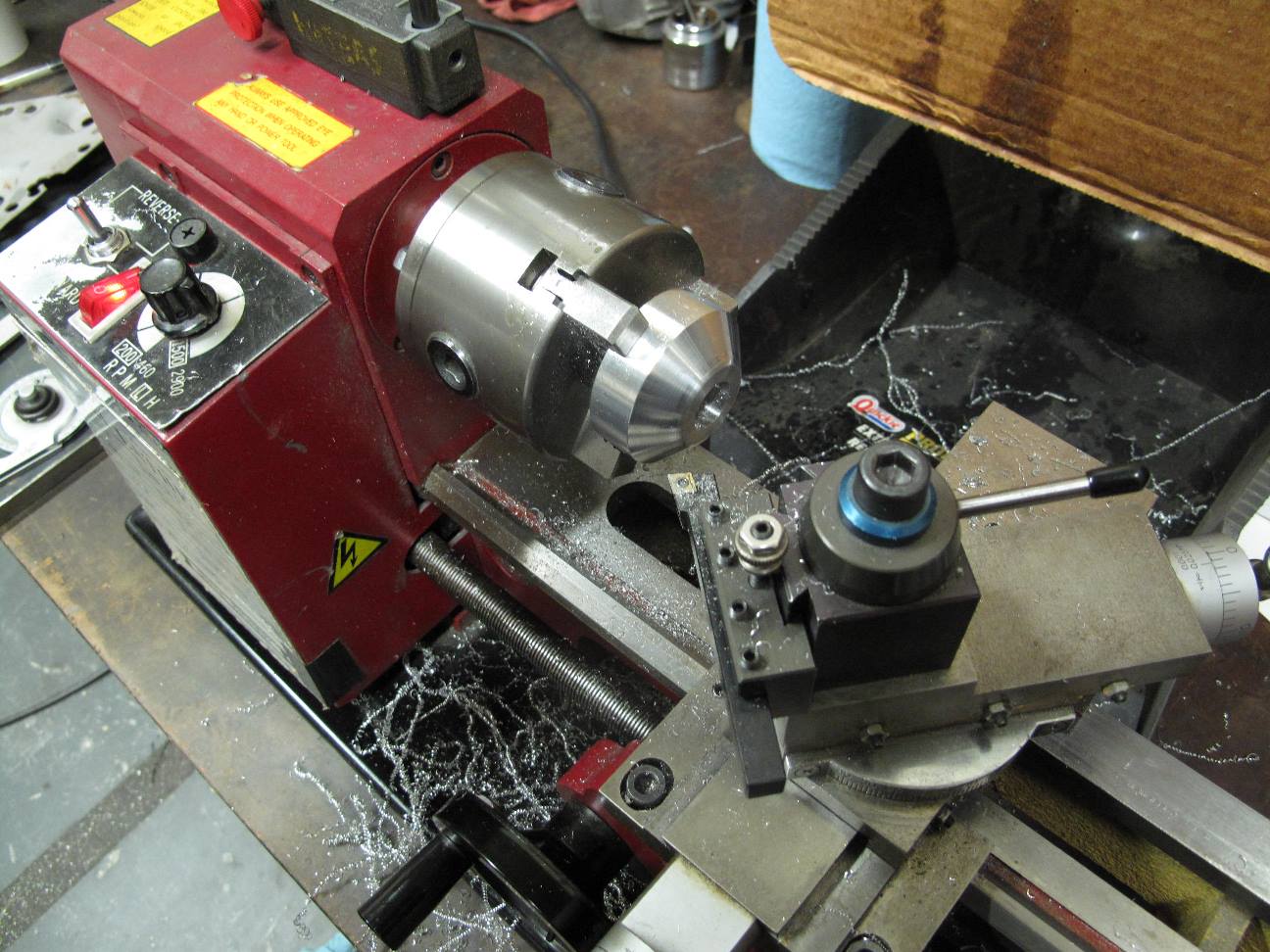

I needed a way to locate the bumper mounting holes. Transfer punch points are too tall to allow them to center in the sheet. If I flipped the sheet over keeping the transfer punch perpendicular would be a pain. So I broke out my trusty Harbor Freight 7 x 10 Mini-Lathe and made some bushings to locate the transfer punch and hold it perpendicular.

I scribed the rest of the spot weld locations and center punched them, locating centers by eye.

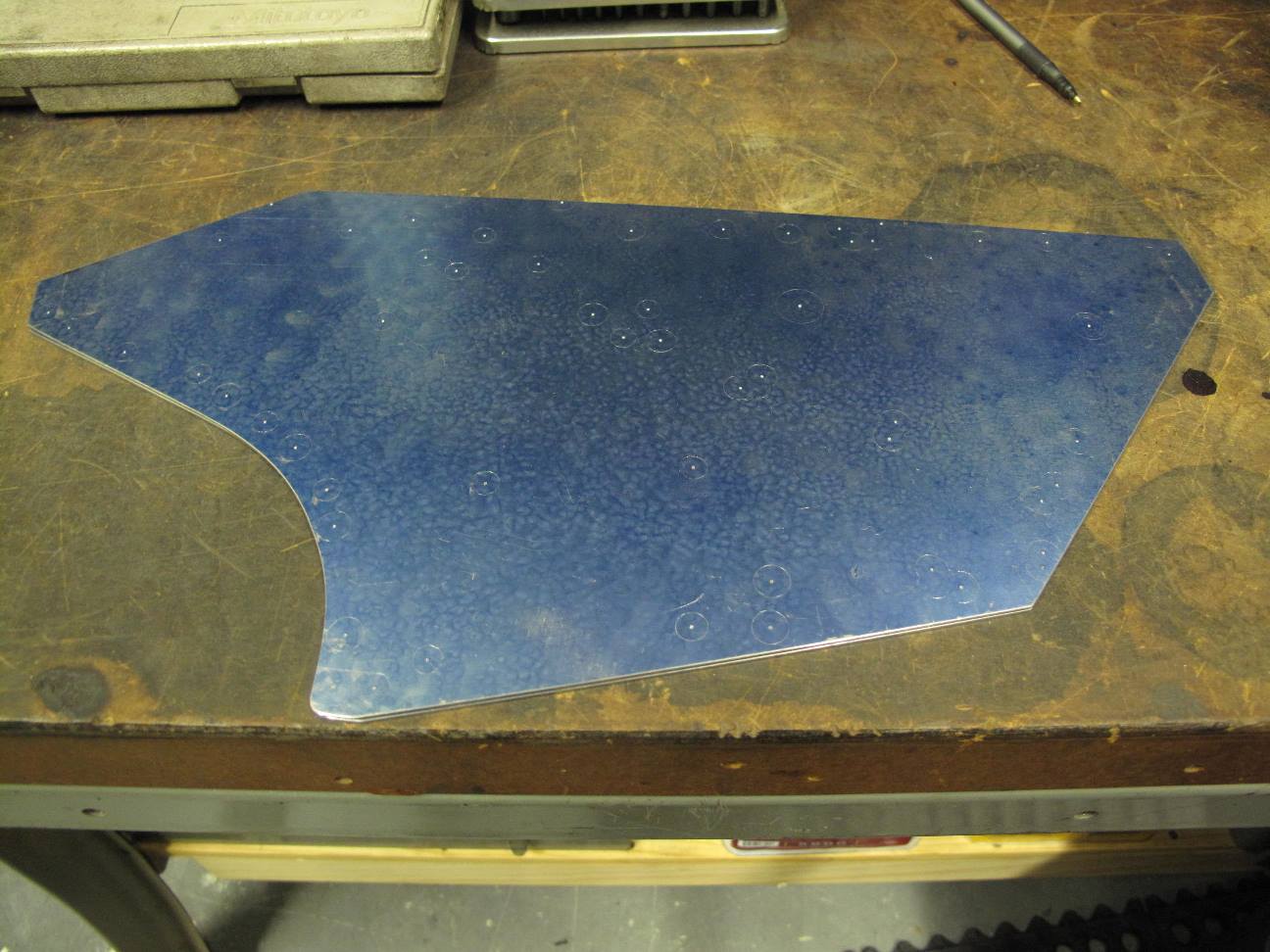

Then the profile was sheared where possible, band-sawed the rest, filed and sanded smooth. I made two in case I scrapped one later or needed one for the opposite side of the car.

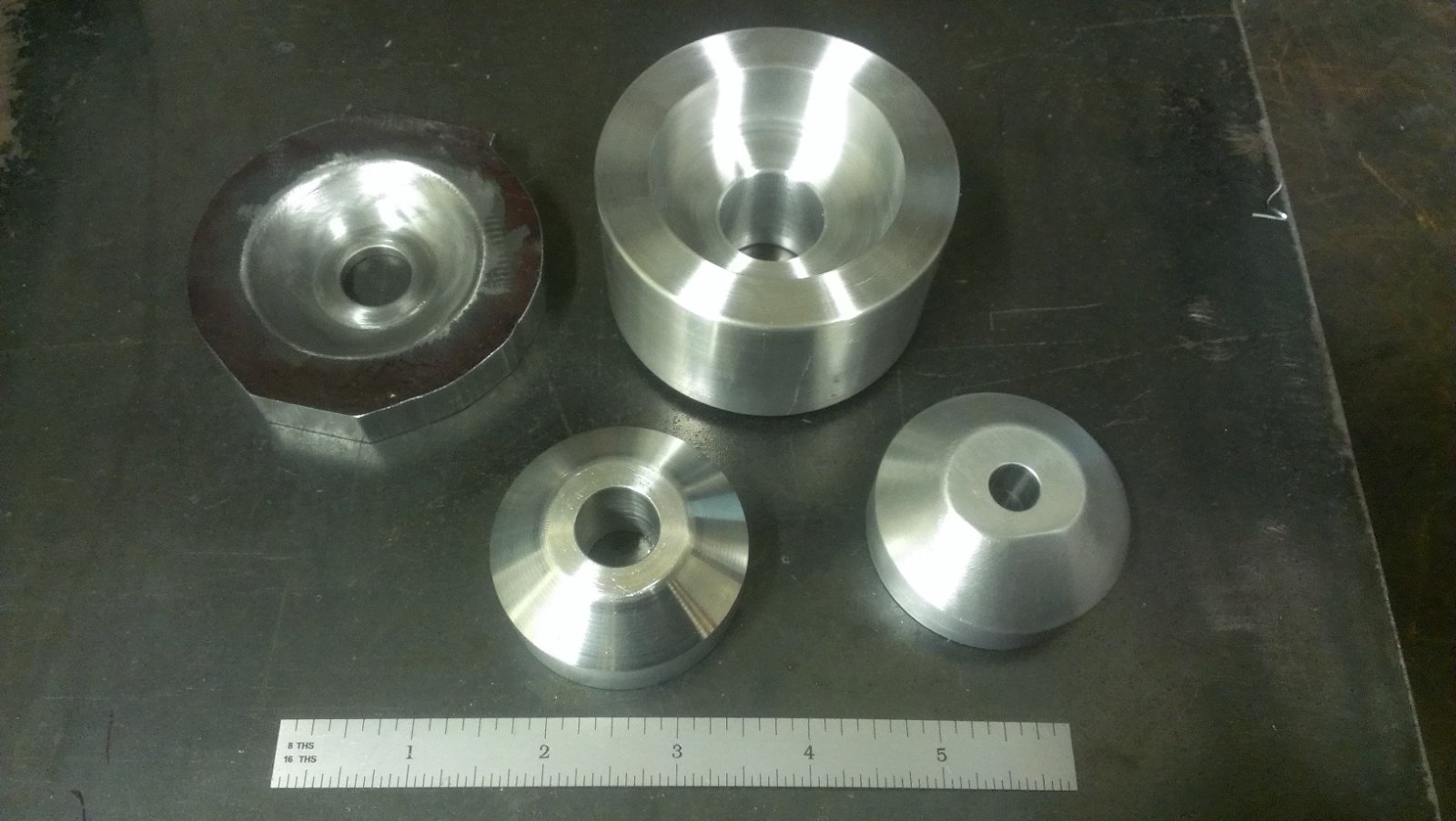

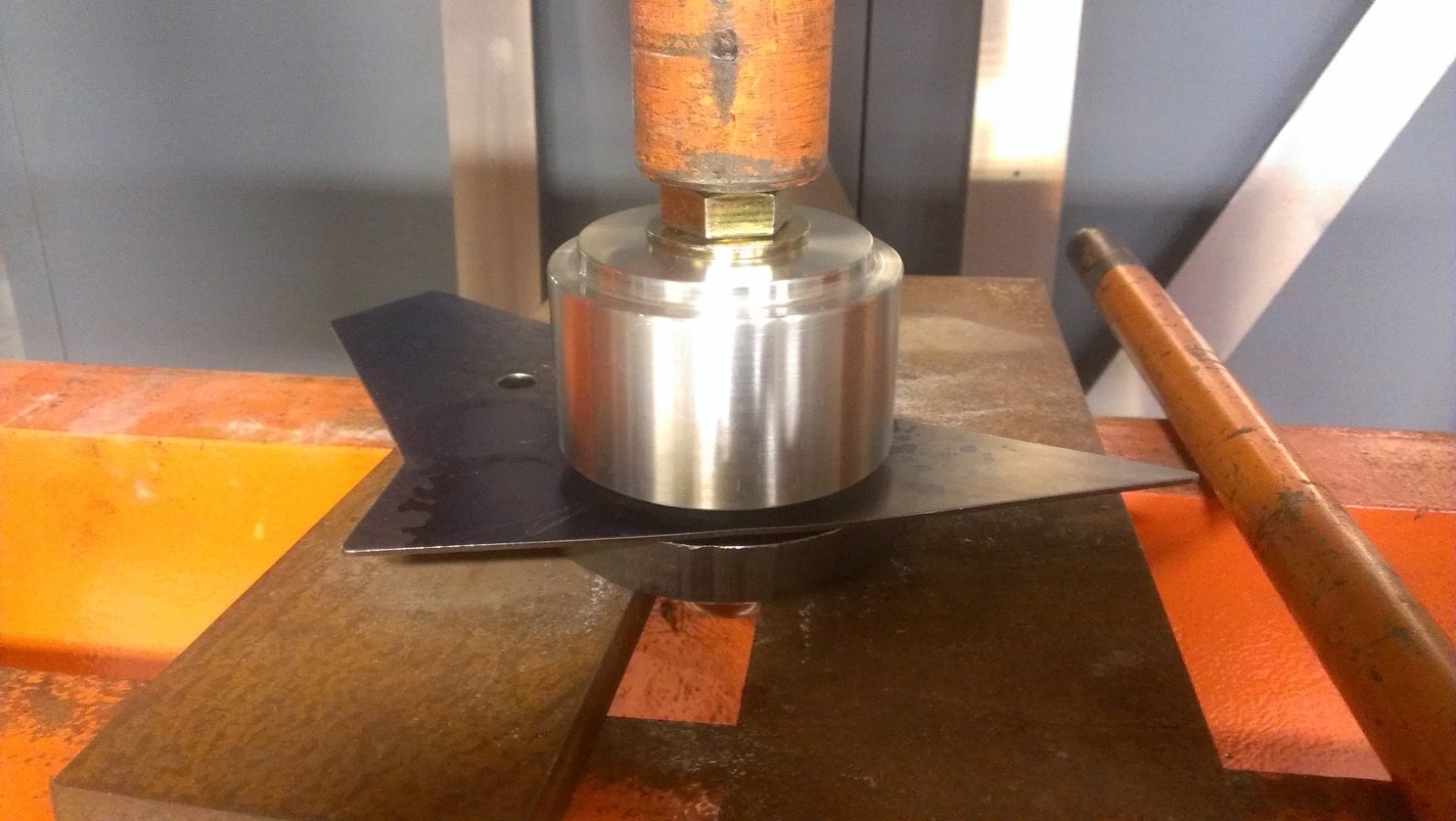

Next, I machined some dies for use in a hydraulic press to make the dimples in the doubler. Back to the lathe. I machined the male side from aluminum bar since they would only be used a few times (and I had it already). The female bottom die was rough cut from hot rolled steel plate and finished on the lathe.

I planned to undersize the holes in the sheet to compensate for stretching of the material, then drill them to size after pressing. I opted to make reducer bushings to allow the use of a smaller fastener to align the dies, as well as to allow the use of a single bottom die.

The dimples caused the flat part to “oil-can” slightly but I was able to heat shrink it flat enough that it would be fine once clamped and spot welded in place.

I think that's it for parts fab. On to rust-proofing and welding things in.

Part made from 1.5mm (16 GA) sheet.

I needed a way to locate the bumper mounting holes. Transfer punch points are too tall to allow them to center in the sheet. If I flipped the sheet over keeping the transfer punch perpendicular would be a pain. So I broke out my trusty Harbor Freight 7 x 10 Mini-Lathe and made some bushings to locate the transfer punch and hold it perpendicular.

I scribed the rest of the spot weld locations and center punched them, locating centers by eye.

Then the profile was sheared where possible, band-sawed the rest, filed and sanded smooth. I made two in case I scrapped one later or needed one for the opposite side of the car.

Next, I machined some dies for use in a hydraulic press to make the dimples in the doubler. Back to the lathe. I machined the male side from aluminum bar since they would only be used a few times (and I had it already). The female bottom die was rough cut from hot rolled steel plate and finished on the lathe.

I planned to undersize the holes in the sheet to compensate for stretching of the material, then drill them to size after pressing. I opted to make reducer bushings to allow the use of a smaller fastener to align the dies, as well as to allow the use of a single bottom die.

The dimples caused the flat part to “oil-can” slightly but I was able to heat shrink it flat enough that it would be fine once clamped and spot welded in place.

I think that's it for parts fab. On to rust-proofing and welding things in.

Last edited:

Simon Oaten

Daily Driver

awesome Courtney !!!!

rgds

simon

rgds

simon

autox19

True Classic

Wow, just freaking WOW. The crazy good talent on this forum amazes me. I go to other forums and they might have a highly technical person. as in one. We are truly blessed to have several. This Same thread in another one would probably have "I bent some metal and made it work (with is my method unfortunately)" This is crazy good showing what Time and talent can do!

Odie

Odie

Rod Midkiff

True Classic

I agree with Autox19. I am quite often in awwww of what some very talented people post. I enjoy my X. But I often feel like a vice grip/hammer mechanic compared to some of the craftsmen that share their work here.

ghostdancing

True Classic

any update on this?

Tom Ginefra

True Classic

Ditto... I thought I was a pretty "handy guy" until I saw the kind of projects our fellow Xweb members take on, and with a quality of workmanship that is often "next level! You folks know who you are. RESPECT!I agree with Autox19. I am quite often in awwww of what some very talented people post. I enjoy my X. But I often feel like a vice grip/hammer mechanic compared to some of the craftsmen that share their work here.

128kid

Courtney Waters

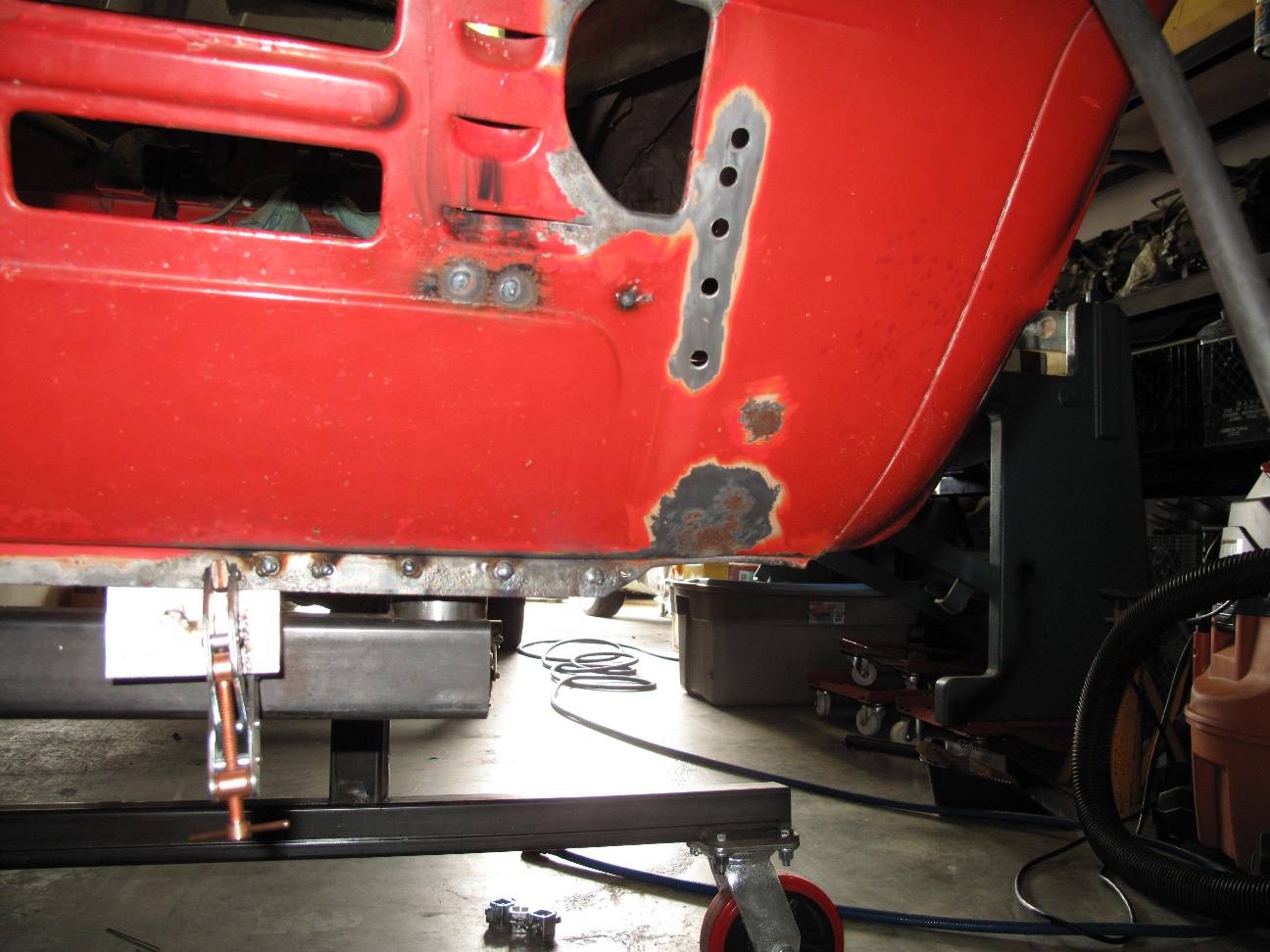

The SL has heen sitting while I worked on a vatiety of other projects (including a lot of restoration & modification to my Rally, story to follow). I still have a few more segments of SL photos to upload to get caught up to date. I should have time to do that in a few weeks. Actual status is the repair to that corner of the SL is complete and I need to start work on the right hand side (which is not as rusty but still needs work). Prior to the rust repair I refurbished a bunch of the suspension and brakes, so that's ready to bolt on when the body repair is done.any update on this?

128kid

Courtney Waters

Rust Proofing

Some of the panels had acquired some surface rust during the time it took to get all of the panels fabricated. I used The Must For Rust to dissolve the surface rust away. The product is also supposed to provide additional corrosion protection by creating a phosphate coating. Time will tell. My experience with this and other rust-conversion products has been mixed… to me, it seems like it flash-rusts the parts. In the future I think I will just sand the rust down the old fashioned way, and then apply epoxy primer.

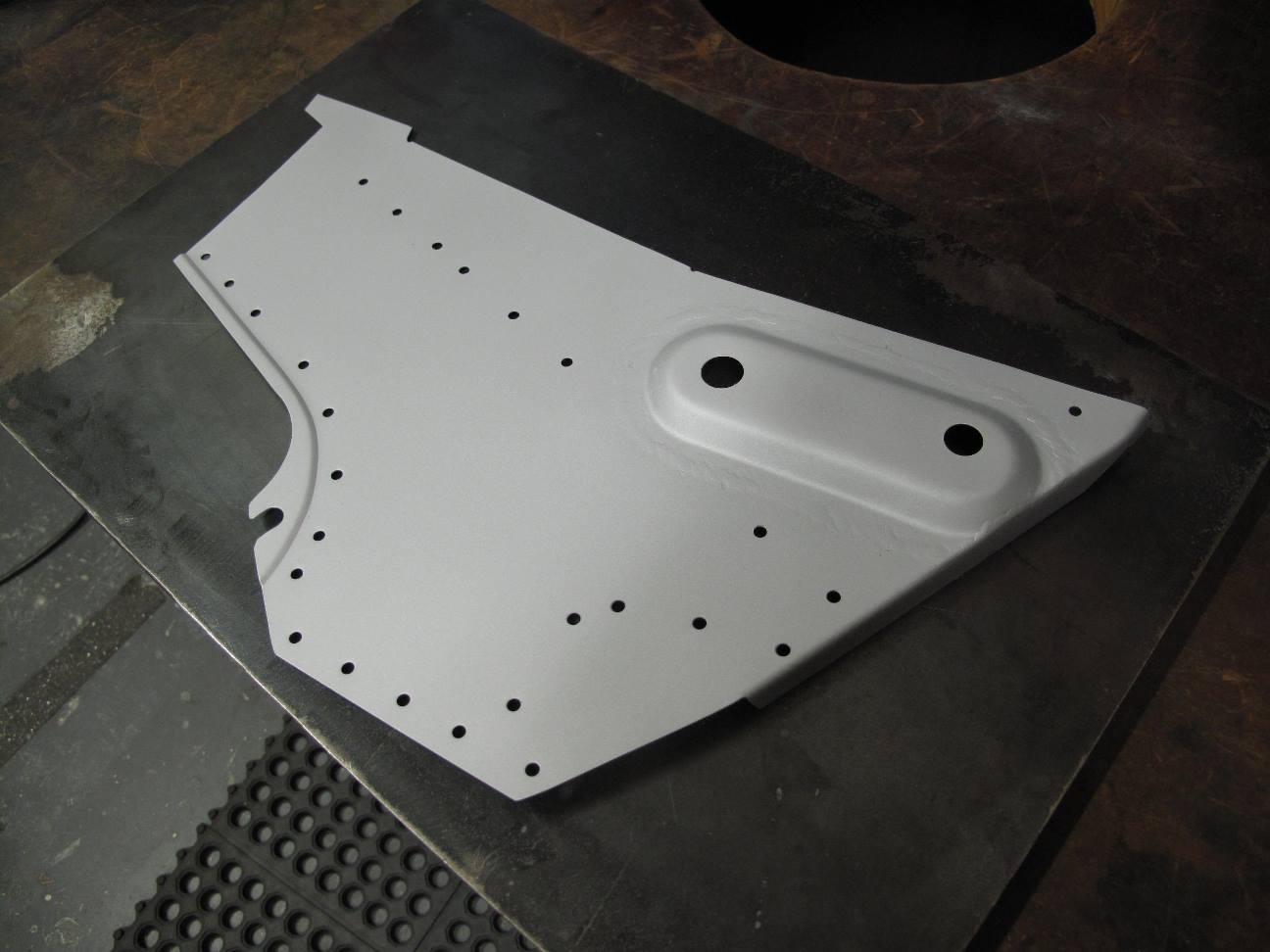

You'll notice that I have added holes for plug-welding the various pieces together. These all duplicate the factory spot-weld locations.

Captive nuts and studs have been welded in at this point.

I then applied PPG Deltron DP40LF epoxy primer to all parts, carefully masking the areas that would be welded. I brushed the epoxy on rather than spraying, just to limit the mess made in my cramped shop.

Next, I removed the masking tape and applied U-POL Weld #2 Weld Thru Primer to the remaining areas.

Some of the panels had acquired some surface rust during the time it took to get all of the panels fabricated. I used The Must For Rust to dissolve the surface rust away. The product is also supposed to provide additional corrosion protection by creating a phosphate coating. Time will tell. My experience with this and other rust-conversion products has been mixed… to me, it seems like it flash-rusts the parts. In the future I think I will just sand the rust down the old fashioned way, and then apply epoxy primer.

You'll notice that I have added holes for plug-welding the various pieces together. These all duplicate the factory spot-weld locations.

Captive nuts and studs have been welded in at this point.

I then applied PPG Deltron DP40LF epoxy primer to all parts, carefully masking the areas that would be welded. I brushed the epoxy on rather than spraying, just to limit the mess made in my cramped shop.

Next, I removed the masking tape and applied U-POL Weld #2 Weld Thru Primer to the remaining areas.

Last edited:

128kid

Courtney Waters

Welding

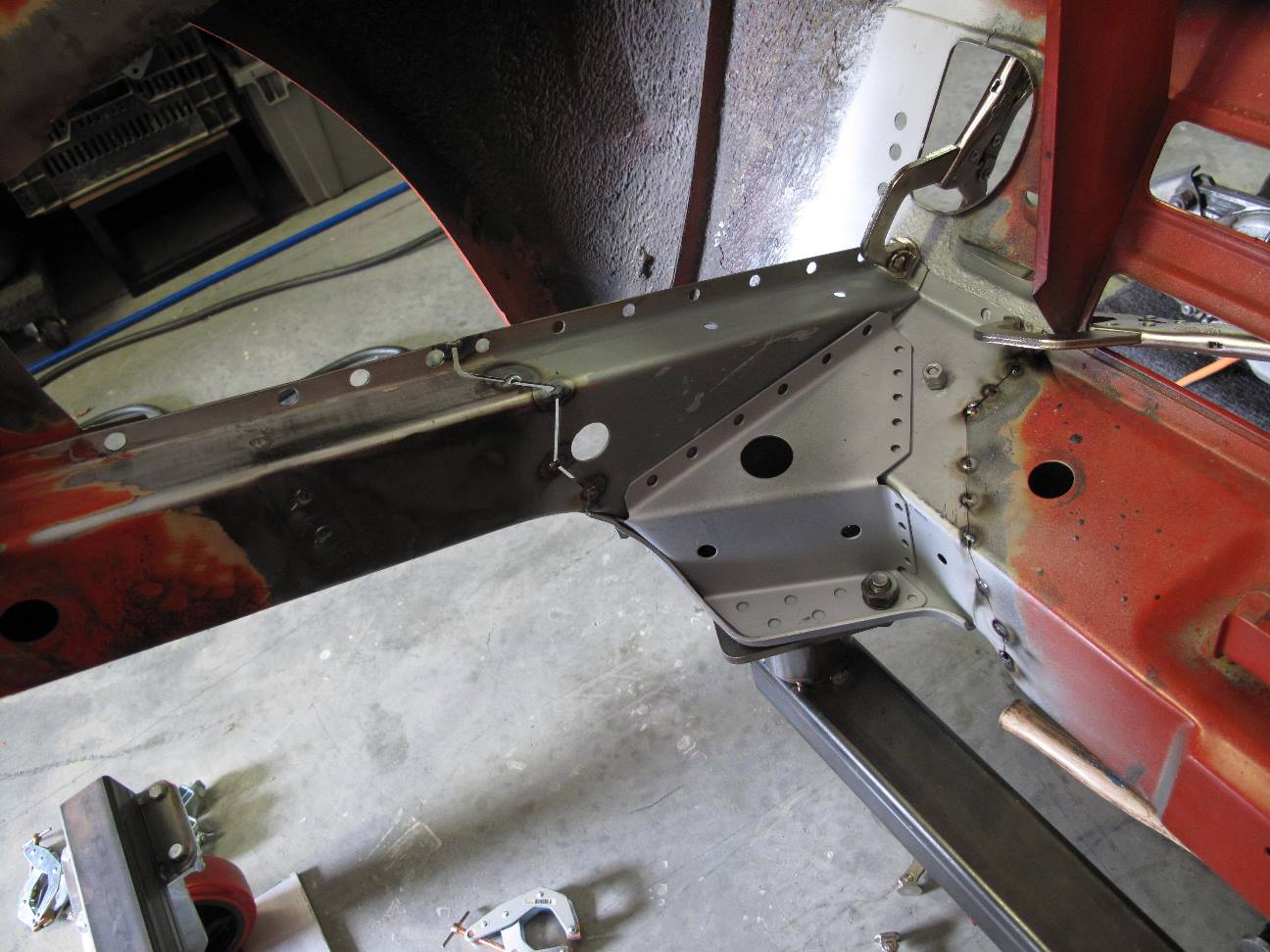

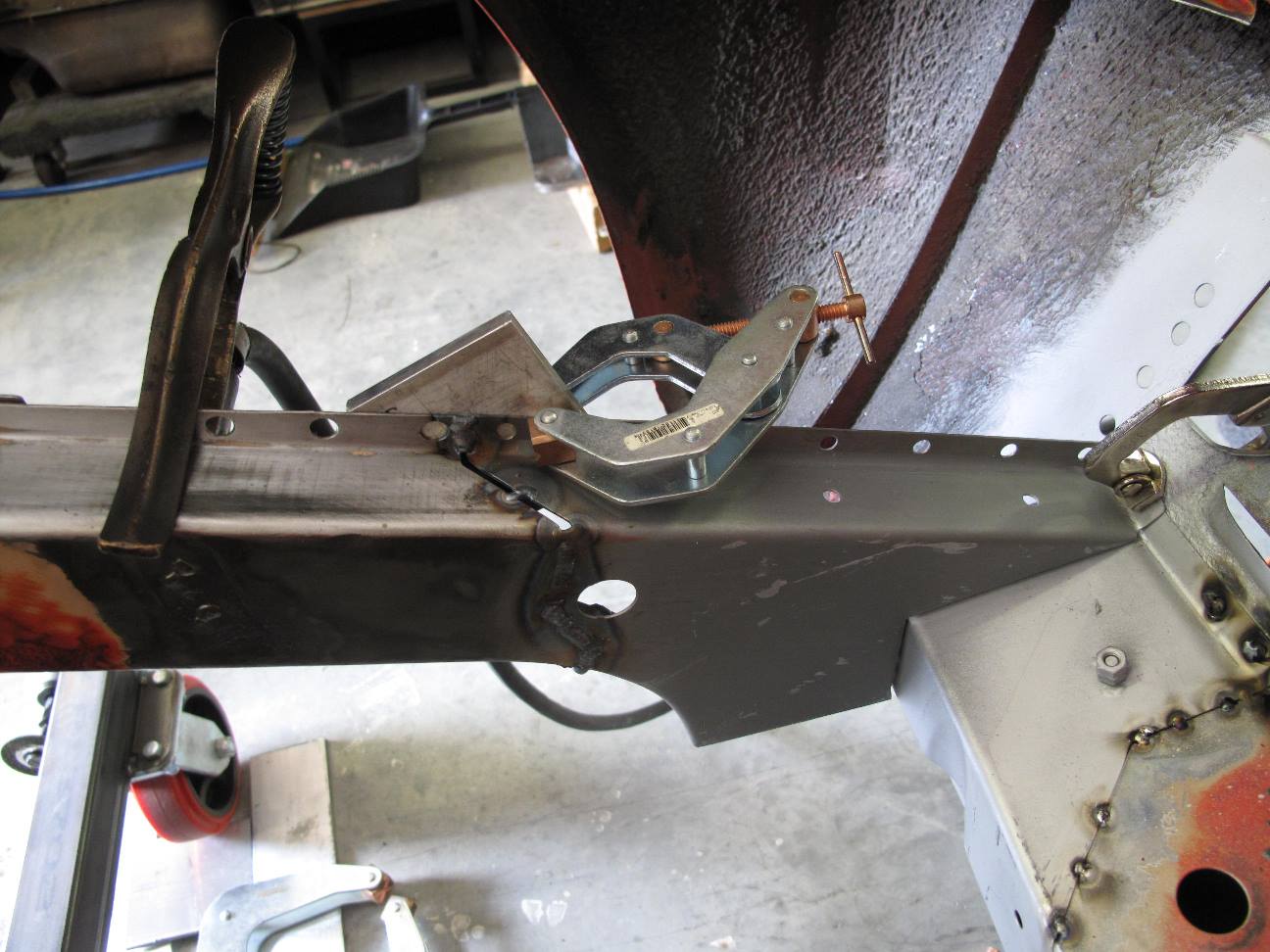

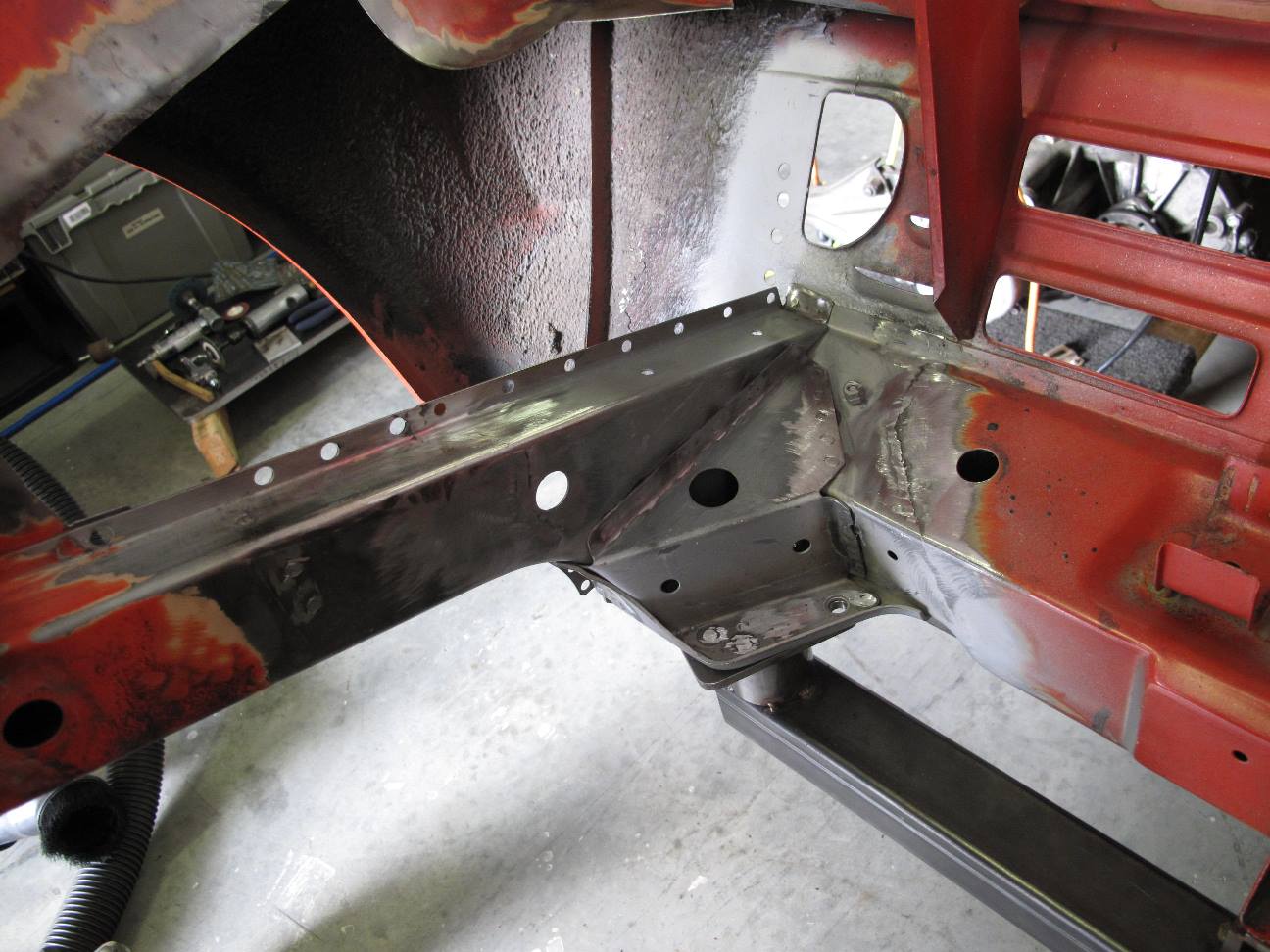

It felt like this day would never arrive… finally, welding parts in for good! The fixture has been bolted back in place, parts carefully fitted and clamped.

The frame rail gap was on the large side so I backed up the joint with an aluminum plate while I stitched the pieces together. This prevents wire birds nests from forming on the back side, and helps draw some of the heat out of the parts to reduce risk of blowing holes in the material. No question about penetration here though!

Grinding the welds down flush. I use a narrow cutoff wheel, mounted on a die-grinder, and work my way carefully across the welds, with the wheel perpendicular to the surface and cutting across the weld. The narrow wheel limits the heat generated so there is less chance of warping. Plus, it’s easier to maneuver in corners.

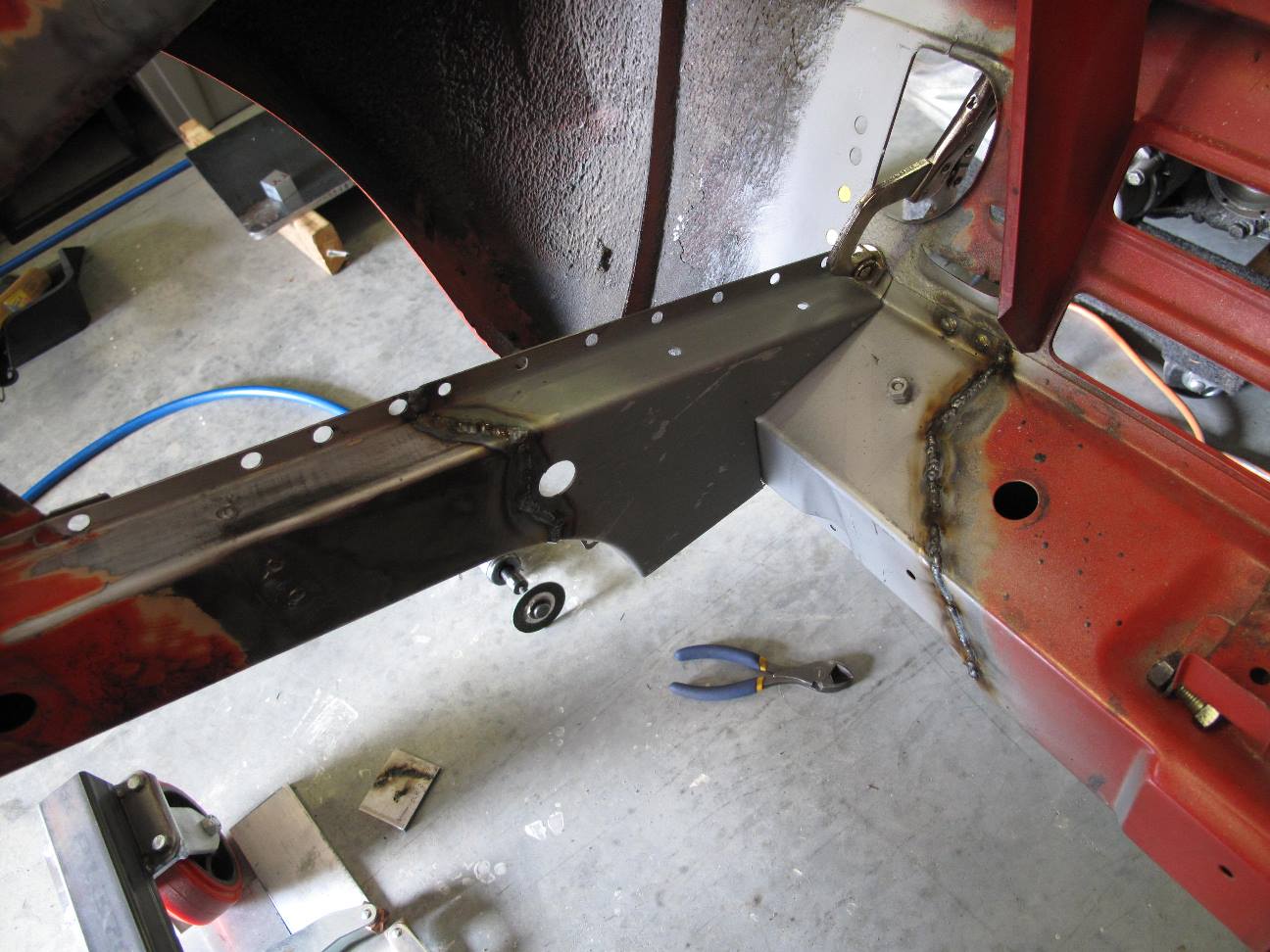

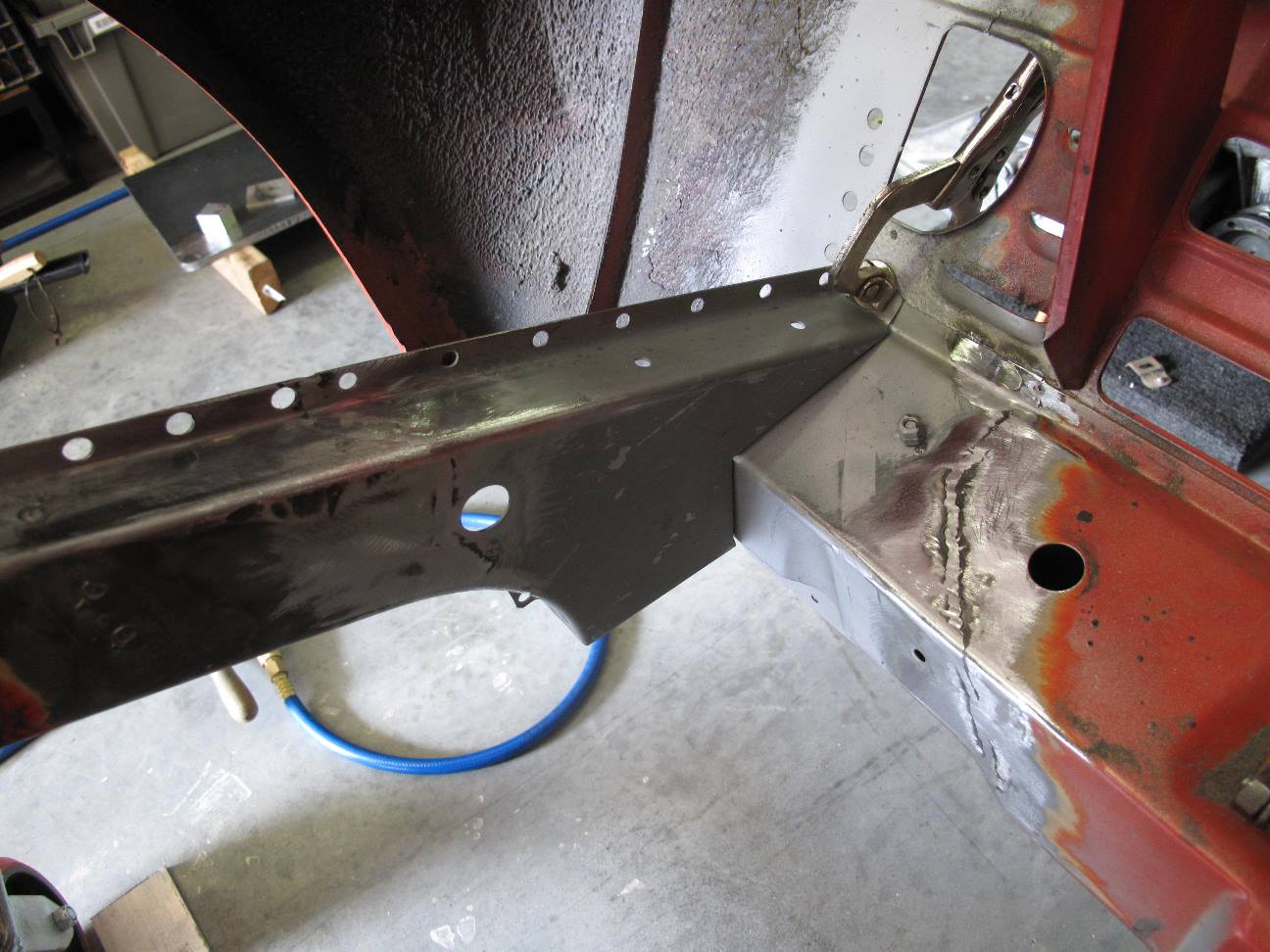

Adding the radius rod mount and corner gusset:

I ground the inside of the frame rail butt weld just to make sure there weren’t any hidden voids.

Painted the inside with PPG Deltron DP40LF epoxy primer. Brushed on instead of spraying (for convenience).

It felt like this day would never arrive… finally, welding parts in for good! The fixture has been bolted back in place, parts carefully fitted and clamped.

The frame rail gap was on the large side so I backed up the joint with an aluminum plate while I stitched the pieces together. This prevents wire birds nests from forming on the back side, and helps draw some of the heat out of the parts to reduce risk of blowing holes in the material. No question about penetration here though!

Grinding the welds down flush. I use a narrow cutoff wheel, mounted on a die-grinder, and work my way carefully across the welds, with the wheel perpendicular to the surface and cutting across the weld. The narrow wheel limits the heat generated so there is less chance of warping. Plus, it’s easier to maneuver in corners.

Adding the radius rod mount and corner gusset:

I ground the inside of the frame rail butt weld just to make sure there weren’t any hidden voids.

Painted the inside with PPG Deltron DP40LF epoxy primer. Brushed on instead of spraying (for convenience).

Last edited:

128kid

Courtney Waters

Welding cont'd

Finishing up the inner panel. I welded the oval dimple in place and ground it down. Then applied weld-thru primer.

Applied weld-thru primer to flanges of frame rail:

Welded in place:

Doubler plug-welded in place:

Tacking the inner fender in place:

My fit-up did not turn out perfect. The part was such a bear to make that I opted to fill the back corner behind the headlight with a sliver of material, rather than make a whole new part. The sliver in the bend could not be avoided without much better metalworking skills than I posses!

The little toenail patch. Took forever!

I’m calling it done for now. It could still use some work to smooth things out a bit, but I’m throwing some primer on it and moving on to the repairs for the right hand side of the car.

Finishing up the inner panel. I welded the oval dimple in place and ground it down. Then applied weld-thru primer.

Applied weld-thru primer to flanges of frame rail:

Welded in place:

Doubler plug-welded in place:

Tacking the inner fender in place:

My fit-up did not turn out perfect. The part was such a bear to make that I opted to fill the back corner behind the headlight with a sliver of material, rather than make a whole new part. The sliver in the bend could not be avoided without much better metalworking skills than I posses!

The little toenail patch. Took forever!

I’m calling it done for now. It could still use some work to smooth things out a bit, but I’m throwing some primer on it and moving on to the repairs for the right hand side of the car.

Last edited:

Simon Oaten

Daily Driver

very nice work Court !

its "better" than new - b/c it wont rust out from the inside out !!!!!

rgds

simon

its "better" than new - b/c it wont rust out from the inside out !!!!!

rgds

simon