lookforjoe

True Classic

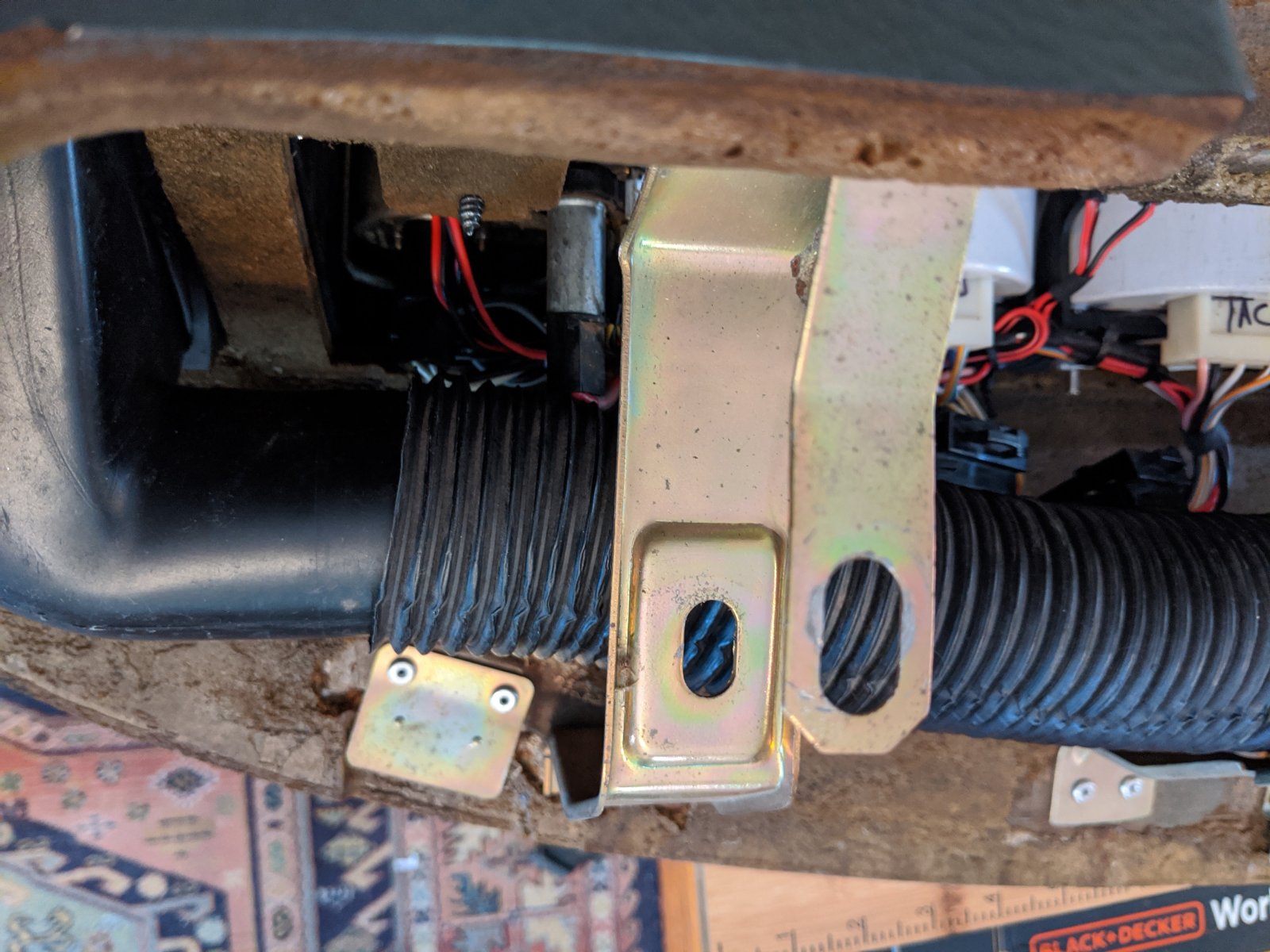

Comparing depth of cluster recess relative to forward mount points. Looking at the fixed angle brackets that locate in the bulkhead tangs - the earlier cluster is approx 2-2.5" further forward (away from the driver) - the vent hose is 2"(ID) .

I think I can gain about an 1" if I cut & angle the side vent tube and use a VW-style aluminum/carboard hose that can be squished into more of an oval cross-section. Heating the stock hose, it pretty much collapses when trying to manipulate the form.

I will have to make my own cluster support brackets & cut off the existing 5 mount points. Those will need to be bonded to the 'rubber' binnacle, hence the question regarding the composite.

I think I'm going to focus on getting the cluster as far forward as possible, then deal with the vent hose after..

Mine

I think I can gain about an 1" if I cut & angle the side vent tube and use a VW-style aluminum/carboard hose that can be squished into more of an oval cross-section. Heating the stock hose, it pretty much collapses when trying to manipulate the form.

I will have to make my own cluster support brackets & cut off the existing 5 mount points. Those will need to be bonded to the 'rubber' binnacle, hence the question regarding the composite.

I think I'm going to focus on getting the cluster as far forward as possible, then deal with the vent hose after..

Mine