Most advise to get the engine running on a project to see what you've got, but looking at the work the PO's "shop" performed I decided to not pass go and collect 200 bucks. Engine has at least 86,000 miles if the odo hasn't spun over once already, so it's better to start fresh anyway. As expected, the head welded itself to the studs. I wasn't going to spend hours machining up a plate to remove the head, and the rope trick while novel, just wouldn't be effective with this level of stuck. To get the head broken free will take either the tool plate or some very high level of "shock" from above. In any case, the studs need to be consistently soaked with Kroil, PB Blaster or whatever your weapon of choice is for a few days before starting. Tapping around with a dead blow hammer is a waste of time and will get you nothing except maybe a damaged head. I decided to make a bracket out of 2 pieces of angle iron welded together in a "Z" configuration. Drilled 2 holes to fit the bracket onto the cambox mounting area of the head, and 1 large hole at the top of the bracket to fit a slide hammer. Bracket fits either right or left of center - only those 2 locations on the stud side. Mounted to left of center first, and gave it 3 stout blows and nothing. I was using a dent puller hammer which doesn't have enough slide weight to get it done. Changed out the slide with the full sized axle puller slide and gave it another 3 whacks. Now the left side of the head had some daylight between it and the block. Moved the bracket to right of center, repeat and all done. If you want to give this method a try, make sure you select a bolt length that provides full thread depth in the cambox mounting holes and the bracket mounting surface is flat and fully tightened down to the head. This is not like removing the front pump from an auto trans. It requires a few

VERY hard hits to break the head loose - hard like pulling a junkyard axle that's been half submerged in water for the past 20 years. All in all the head can be removed fairly painlessly and quickly. The only downside is having to put the job on hold while the penetrating fluid does it's job. The upside is the bracket takes about 15 minutes to fabricate and can be thrown together with scrap probably laying around the garage somewhere.

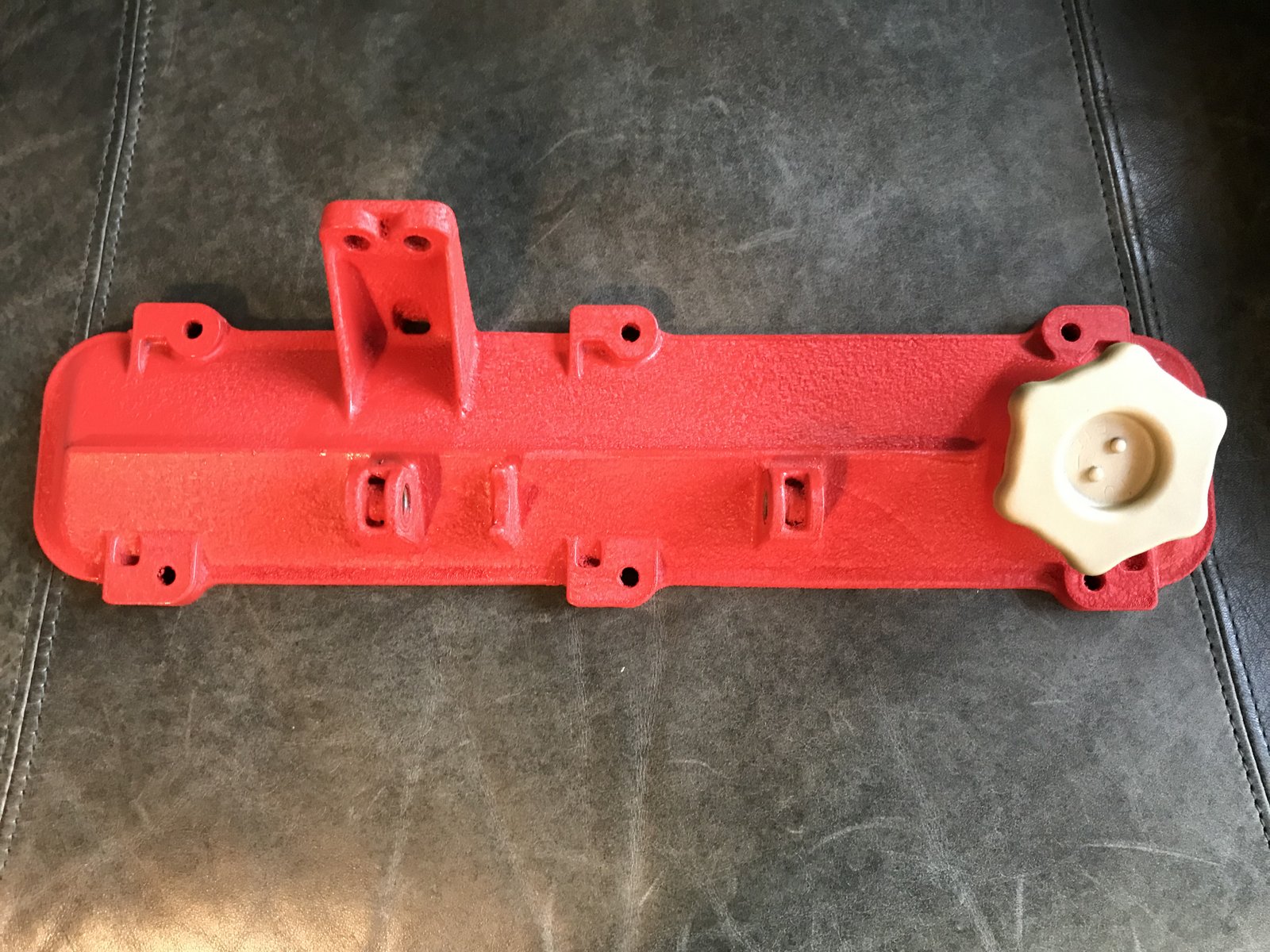

View attachment 50393

. Doesn't make the engine faster, better, or last any longer, but it does fool you into thinking you're making progress.

. Doesn't make the engine faster, better, or last any longer, but it does fool you into thinking you're making progress.