TonyK

True Classic

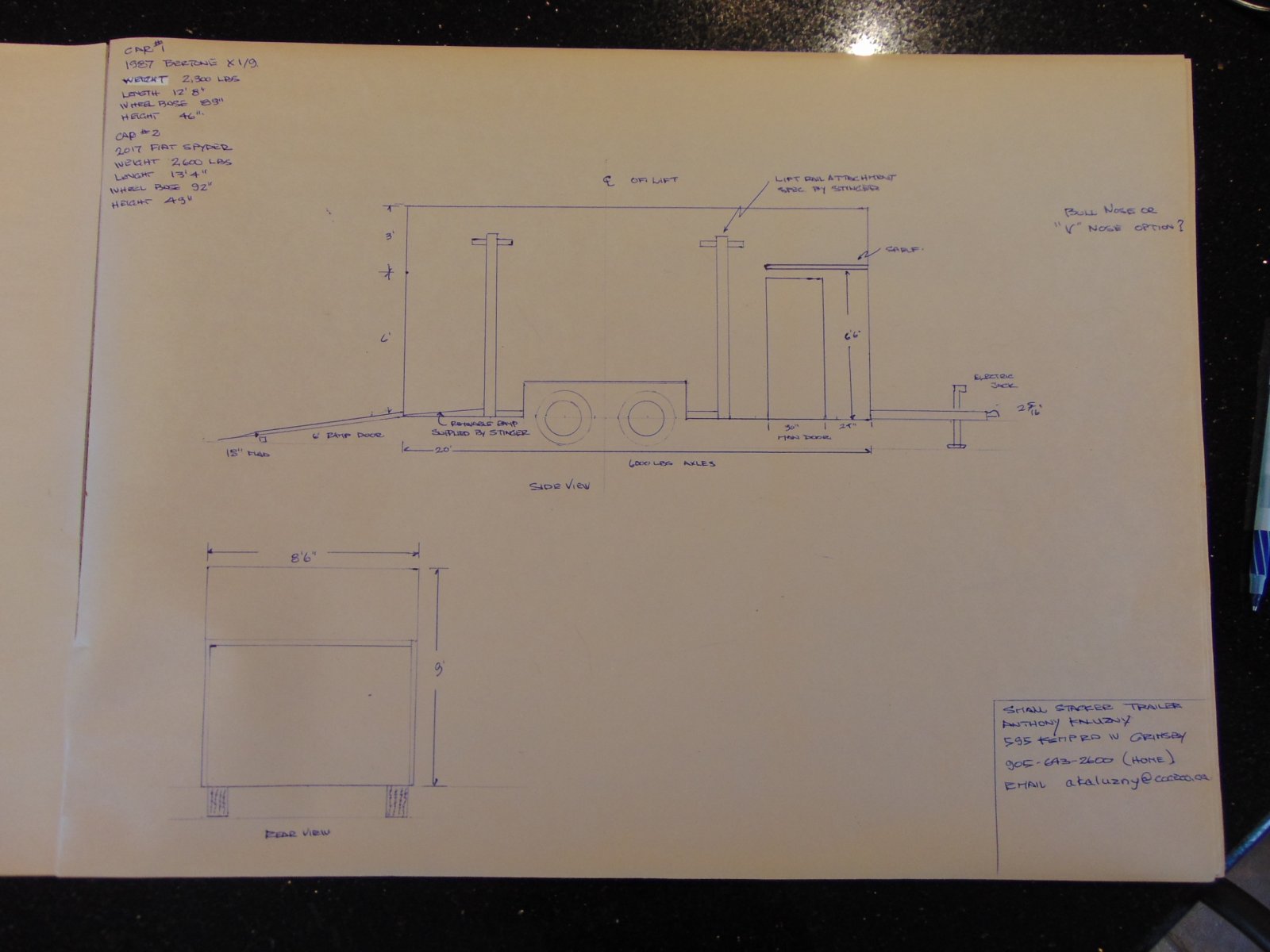

This year Bob Martin and I will be attending FFO 2022. The intent is that we will trailer 2 cars together. So let us back up a bit. My wife Sarina purchased a 2017 Fiat 124 Spyder with 5,000 miles on it. She has been attending FFO with me since 2005 and finally at Green's Borough said I want my own car and that is what she did. Now comes the conflict, who's car to take to an event. So, searching the intra net I found the solution, a stacker trailer. A custom stacker trailer. Well as events go the issue at hand was that there was a conflict for FFO 2022. Sarina has a business trip to attend in Jamaica with 12 other ladies and it is the same dates as FFO 2022. The solution was that Bob Martin and I will attend together. Just to let you know Bob is stage 4 prostrate cancer. He is doing fine currently, gets a bit tired through the day but is managing. Confronted with all of this I made a decision to source out a manufacture that builds stacker trailers. I don't need to move 2 Escalades but rather 2 Fiat's. I need an enclosed 20 foot trailer with an interior head room of 9' ( feet). Simple. But what I got was argument and reasons why I should have 11 feet clearance and 24 feet in length. All costing a lot of money that at this time I said well this is plain stupid. I found one local builder that said he could do it and then 3 months ago backed out he was just too busy to take on the project. The solution is that Bob and I will rent a 24' flat bed trailer from Grimsby Ontario and I have built some ramps from 2 X 12's that are 14' long and will install 40' of E track to secure my car, then trailer to Bob's and load his car and a day or so latter and the adventure will begin as my Ram 2500 with a 6.7 Cummins manual 6 speed hits the road for the Woodlands Texas. I will update this thread as we proceed to FFO 2022.

So I have a few pictures for you. The trailer that I had hoped to have built for the trip and the ramps that I have currently built to load the 2 cars on the flat bed trailer.

Say a prayer. FFO here we come.

TonyK.

Grimsby Ontario Canada.

So I have a few pictures for you. The trailer that I had hoped to have built for the trip and the ramps that I have currently built to load the 2 cars on the flat bed trailer.

Say a prayer. FFO here we come.

TonyK.

Grimsby Ontario Canada.