You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1976 Scorpion; Gold

- Thread starter icr

- Start date

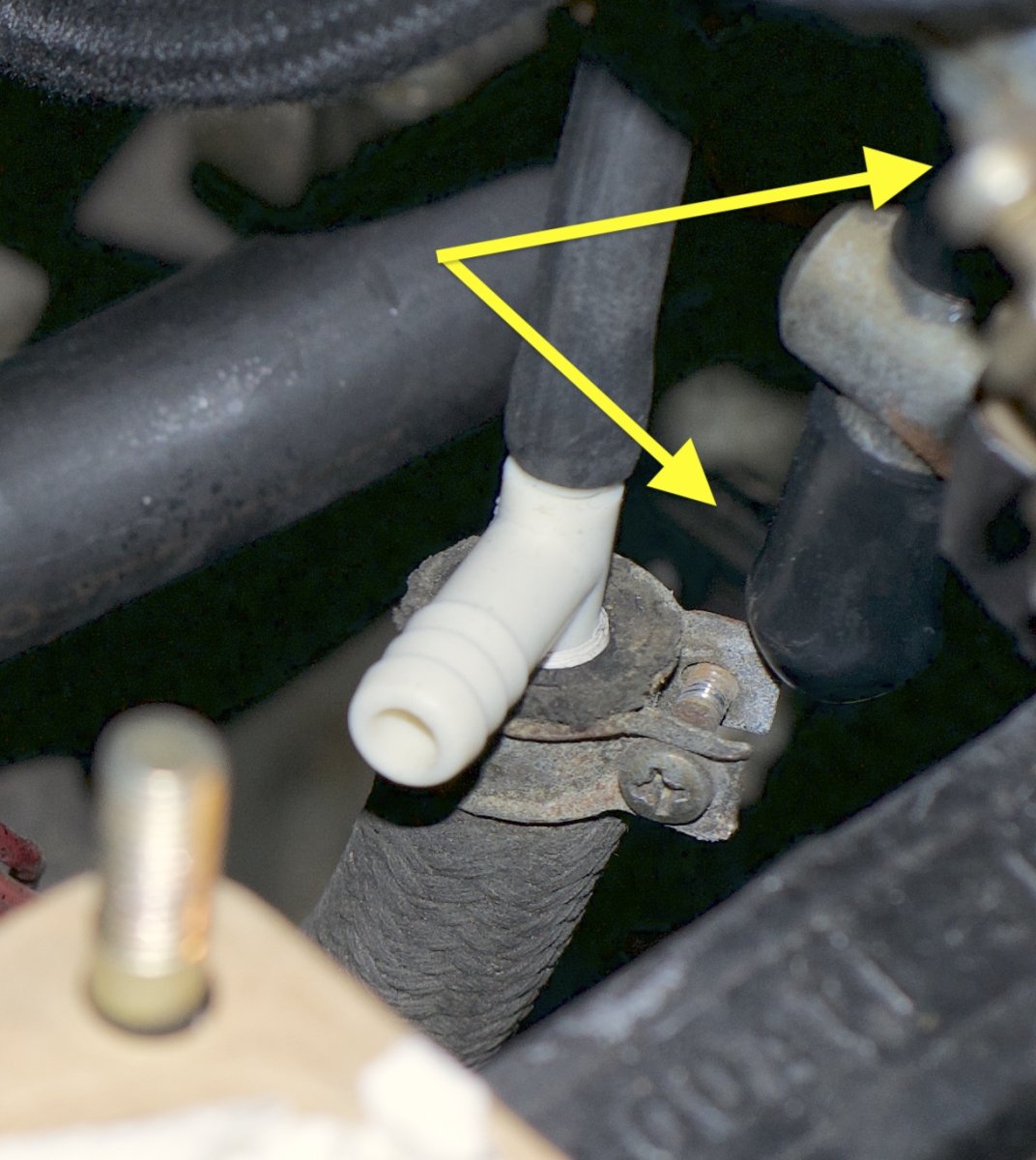

This is the 3-way vacuum connector in place. Yellow arrows show the caps on the Alquati intake manifold vacuum fitting.

So, using my home-made 3-way fitting, the two existing vacuum hoses can be used because the 3-way fitting is right by the old fitting on the intake manifold. And, with the new vacuum line at a 90 degree takeoff, it will run under the carbs and under the throttle assembly.

So, using my home-made 3-way fitting, the two existing vacuum hoses can be used because the 3-way fitting is right by the old fitting on the intake manifold. And, with the new vacuum line at a 90 degree takeoff, it will run under the carbs and under the throttle assembly.

Last edited:

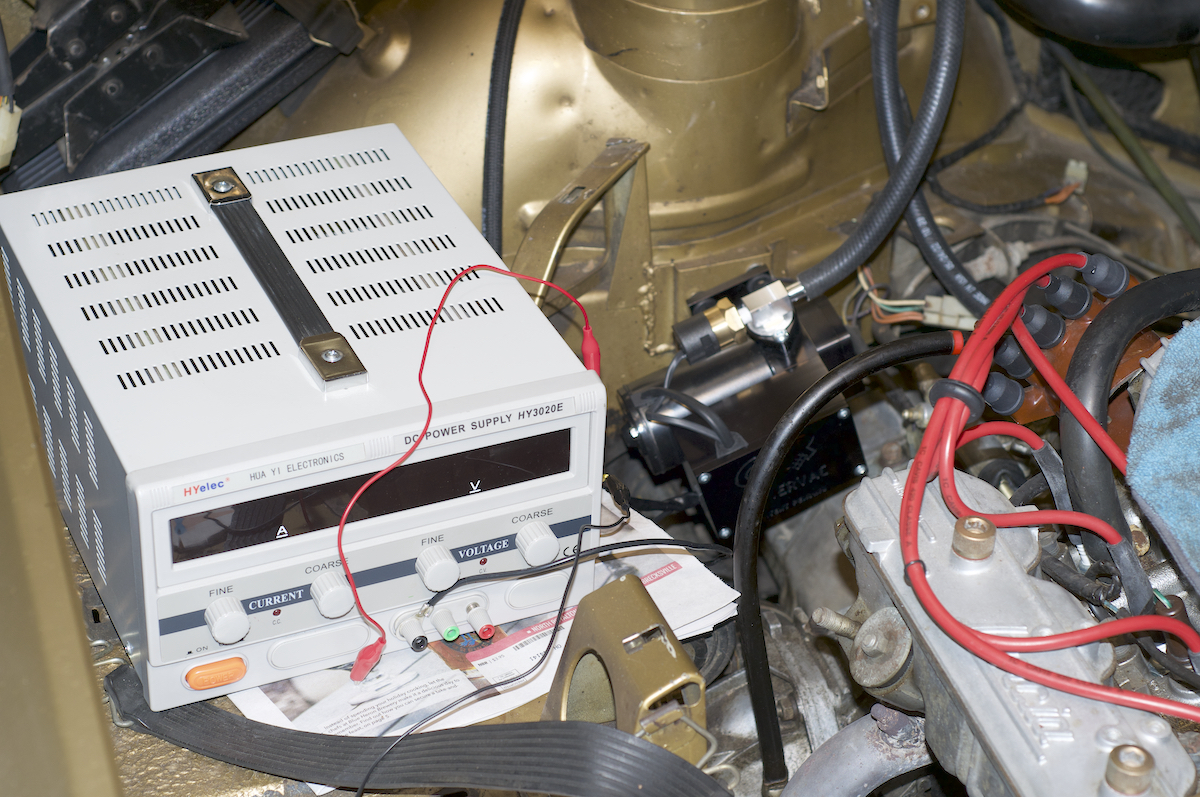

In between the carbs there is an opening in the intake manifold so I can see the nut on the starter solenoid. This is where power will go to the vacuum pump. The nut has been loosened, but I have not connected the wire. I need to back feed the entire length of the wire through the rubber grommet (not shown, pulled back).

Of note the line with the yellow arrow connects to a 6mm nipple on the gas tank, the others are all 8mm. So that line is smaller. That used to be the return line from the carb, but the DCNFs don't need that so I tapped it into the fuel-air separator system and it functions as a third tank breather.

Testing the pump connected to the car's vacuum system.

The heater controls now function, I can hear the flaps opening and closing.

However, there is no vacuum reaching the brake servo. I suspect a stuck check valve. With the vacuum pump and its sensor, no check valve is needed. I'll try to remove the check valve from the circuit, though it may be part of a banjo-bolt fitting on the servo.

The heater controls now function, I can hear the flaps opening and closing.

However, there is no vacuum reaching the brake servo. I suspect a stuck check valve. With the vacuum pump and its sensor, no check valve is needed. I'll try to remove the check valve from the circuit, though it may be part of a banjo-bolt fitting on the servo.

Dean Scharer

True Classic

Ray at Performance Apex told me to have you call him if you have any questions about your car’s brake setup.On my white 77, it has supposedly been upgraded with Fiat 124 brakes and master cylinder, no booster. Work was done by Performance Apex, so I am confident it was done correctly, but the brake pedal is quite hard, so I need to through everything again. There is also a manual brake bias valve in the circuit, but have not looked that closely yet at the details. The red 76 seems to have completely stock everything, but the brakes are also hard, so I suspect the booster is just disconnected.

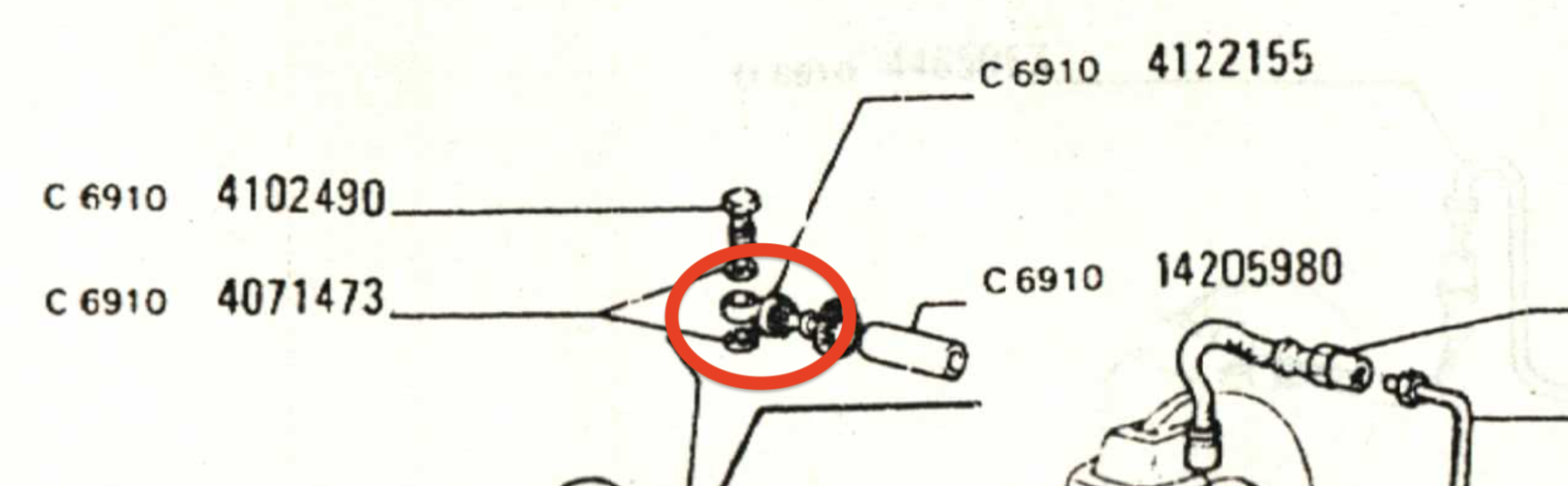

Followup on the check valve. The 22mm banjo bolt holding it in place is not easy to loosen. The whole booster mounting bracket assembly bends slightly with the torque I put on the bolt with a 22mm combination wrench.

Further testing with the vacuum pump and gauge reveals vacuum is in deed being produced in the booster. But no boost. Need to investigate further.

Further testing with the vacuum pump and gauge reveals vacuum is in deed being produced in the booster. But no boost. Need to investigate further.

Last edited:

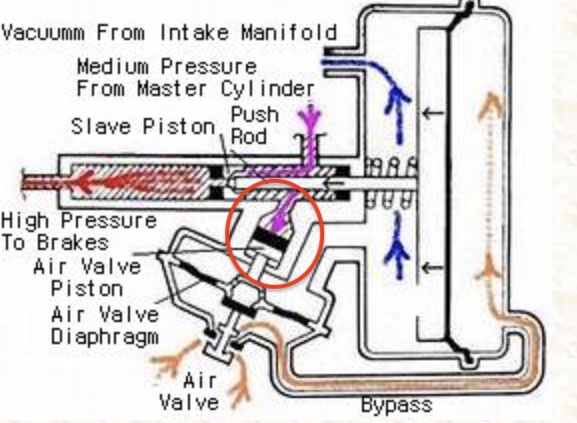

I was able to remove the air valve and it is OK. The problem seems to stem from the Air Valve Piston not moving when the brake pedal is depressed. So the Air Valve won't open to let atmospheric pressure in to the other side of the booster diaphragm. So both sides of the booster diaphragm are in vacuum all the time and there is no bake assist.

kmead

Old enough to know better

You might consider putting a small fuse panel in back there when you take off power at the starter. This way you could have power for a starter relay, the vacuum pump or any other accessory you may want to add over time back there. This way you don’t have to keep going back to the well so to speak when your needs change.

Just a thought.

Everything looks great. Very thoruough.

Just a thought.

Everything looks great. Very thoruough.

NigelProdrive

True Classic

There is another reason owners bypass and remove the brake booster. They fail. And add 20 feet of brake line into the system. One magazine article said tongue in cheek that by the time the pressure went back to booster and came back to front brakes that you'd already be past what you were braking for.

If you are messing with starter the new high torque starters available are much more compact making working in that area easier, 9 pounds lighter and have much better electrical connectors than the original.

If you are messing with starter the new high torque starters available are much more compact making working in that area easier, 9 pounds lighter and have much better electrical connectors than the original.

I checked it out; Good Call on that!I bel 69 Alfas used the same part.

I also contacted the UK based organizations JL Spares and Powertrack Brakes (URLs below) and USA based Apple Hydraulics, to price a re-build. Usually I'd do that myself, but the stuck air-valve piston won't get better by itself by doing a 'rebuild' myself as there are no parts related to that piston in the rebuild kit. The piston would still be stuck. I'd want a pro-shop to deal with it.

www.applehydraulicsonline.com

www.applehydraulicsonline.com

Contact Us

Hey there! Looks like you have a question. We'll gladly answer it for you. We suggest checking out the FAQ section as pretty much every question is answered there. You may also reach us at the following contact details: Email: Info@applehydraulics.com Address: 1610 Middle Rd, Calverton NY 11933...

Classic Car Brake Parts - PowerTrack Ltd - for brake parts for classic cars and commercials and vintage vehicles

We stock an extensive range of brake shoes, discs and drums for classic cars and vintage vehicles. Most are available for same day despatch

www.powertrackbrakes.co.uk

Last edited: