You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Car So Far...

- Thread starter Ben Louis

- Start date

Dr.Jeff

True Classic

Best method would be by checking the weight at each corner (corner scales), and adjusting the coil-overs by weight not ride height. There are other factors to consider as well, and it gets a little involved. So rather than getting into one of my long/wordy explanations, I'll suggest looking online for some info about that...much more efficient for you, trust me.

Ulix

True Classic

Ok so question:

- Is a bit of rear ride height beneficial to handling? The idea being to load the front some more to make up for the X not being very close to 50:50

The X drives best with the nose higher than the rear, as original.

Unfortunately that is not what looks best, so most people go for equal height or a lower front.

Steve Hoelscher

True Classic

Best method would be by checking the weight at each corner (corner scales), and adjusting the coil-overs by weight not ride height. There are other factors to consider as well, and it gets a little involved. So rather than getting into one of my long/wordy explanations, I'll suggest looking online for some info about that...much more efficient for you, trust me.

While corner-weighting is always a good idea to help balance the car's handling you really can't effect weight distribution with weight jacking. F/R and L/R weight is what it is. Raising or lowering one end or side will not have any significant effect. To effectively change the car's weight distribution you need to actually move the weight's position on the chassis.

Raising or lowering either end of the car (rake) affects the car's handling by changing the roll centers and roll axis (the two roll centers relative to each other), and to some extent, aerodynamics. At OE ride height the car's roll centers are excessively high. Most of us prefer to have the car either level or the front slightly lower than the rear for aesthetics. The effects on handling are improved turn-in and improved front grip. This is mostly due to the change in roll axis inclination because the front roll center is now below the rear. If the rear roll center is below the front it helps calm the car's oversteer, especially in transition. However, either condition can be mitigated with the tuning of spring rates and/or swaybars.

DanielForest

True Classic

Yes. At least in North America.

Ben Louis

True Classic

Thanks for the weigh ins and info

In the end I decided to set the car with as close to level a ride hieght as possible. Although I guess its the cars lines or something which make it look a bit lower in the front to me when I look at it.But, nope Ive put a rule to it and shes level.

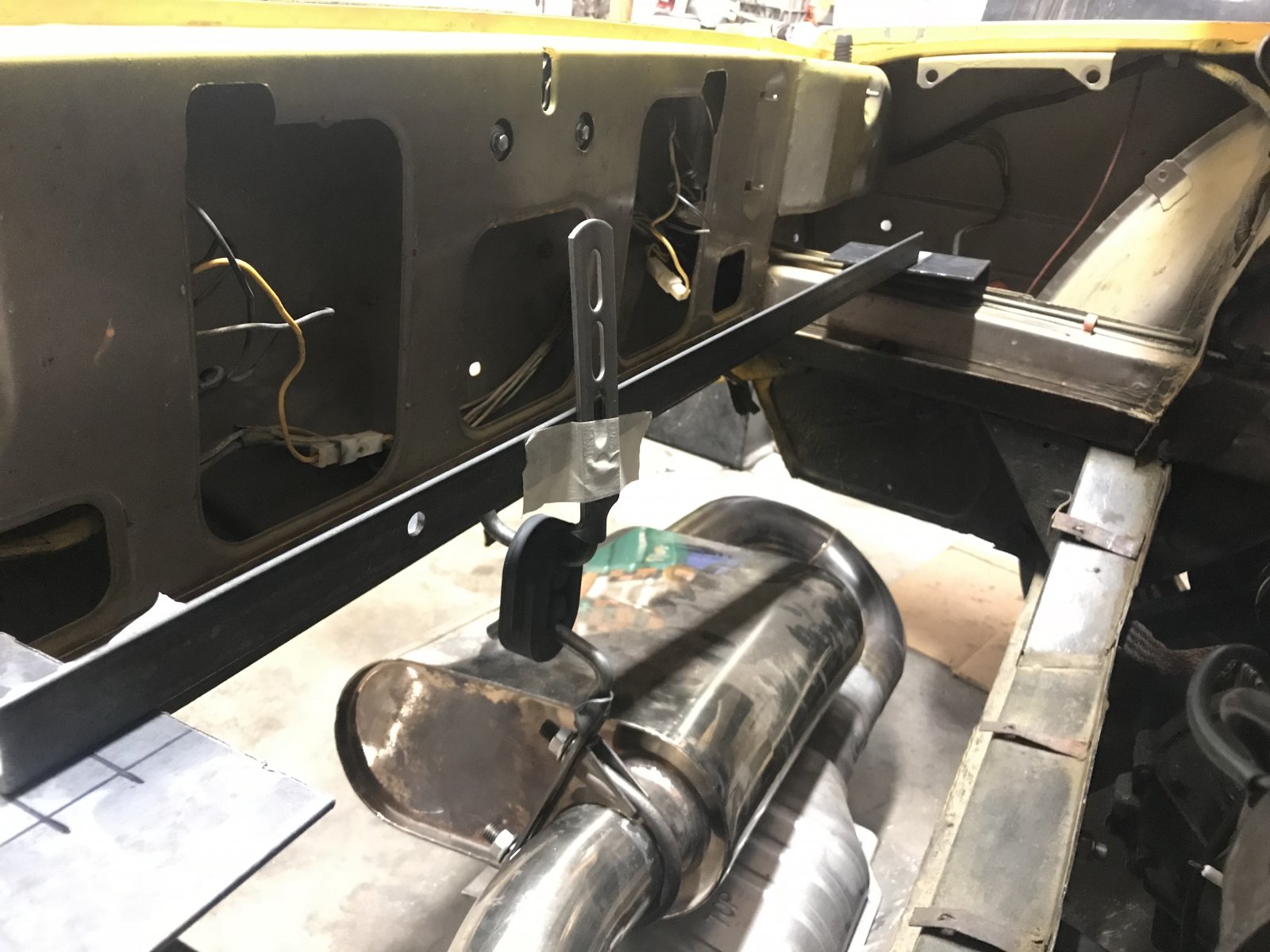

Now that things are starting to roll, I tackled the exhaust. The previous hanger situation I had setup was ok but only just. So I decided to do a brief re design

Keep in mind Ive never had a trunk as most of the rear compartment and exhaust structure was already removed when I bought it. Plus I am using a repro type trans mount without the hanger. And also raiding the metal scrap pile to make it happen

Starting the end brackets. I dont know what these bolts did (rear bumper?) but theyre beefy and seem up to supporting some weight.

Another view

Quick mockup and think session

Figuring out first hanger

In the end I decided to set the car with as close to level a ride hieght as possible. Although I guess its the cars lines or something which make it look a bit lower in the front to me when I look at it.But, nope Ive put a rule to it and shes level.

Now that things are starting to roll, I tackled the exhaust. The previous hanger situation I had setup was ok but only just. So I decided to do a brief re design

Keep in mind Ive never had a trunk as most of the rear compartment and exhaust structure was already removed when I bought it. Plus I am using a repro type trans mount without the hanger. And also raiding the metal scrap pile to make it happen

Starting the end brackets. I dont know what these bolts did (rear bumper?) but theyre beefy and seem up to supporting some weight.

Another view

Quick mockup and think session

Figuring out first hanger

Dr.Jeff

True Classic

The amazing part of it to me is how you are able to take so many photos, write up all the descriptions, and post it all. Often I think about trying to do this but I barely have time to do any actual work on my cars, let alone all the media stuff. Guess in part it might be a function of our generations; we did not grow up constantly holding a phone camera and taking pictures of ourselves/food/friends/pretty much nothing all the time and posting it on social media. We were too busy getting on with real life to sit around telling the world about it.

But seriously, nice work, keep it up.

But seriously, nice work, keep it up.

Ben Louis

True Classic

View attachment 12206 Any chance of thinking about this a little differently?

I think your design is actually a better solution overall. I considered it first actually, though less well developed than yours. Problem is that the bolts on the inner face of the rail dont go all the way through. There is a metal lip that just impedes using the threads from that direction and enabling a flat face to mount to. Considering how unceremoniously material has already been removed from the back end I just couldnt bring myself to cut anymore esp at the frame rail. Admittedly my solution is a work around. But I tend to be one of those “nothing is ever finished” types so I may come back and redesign again at some point.

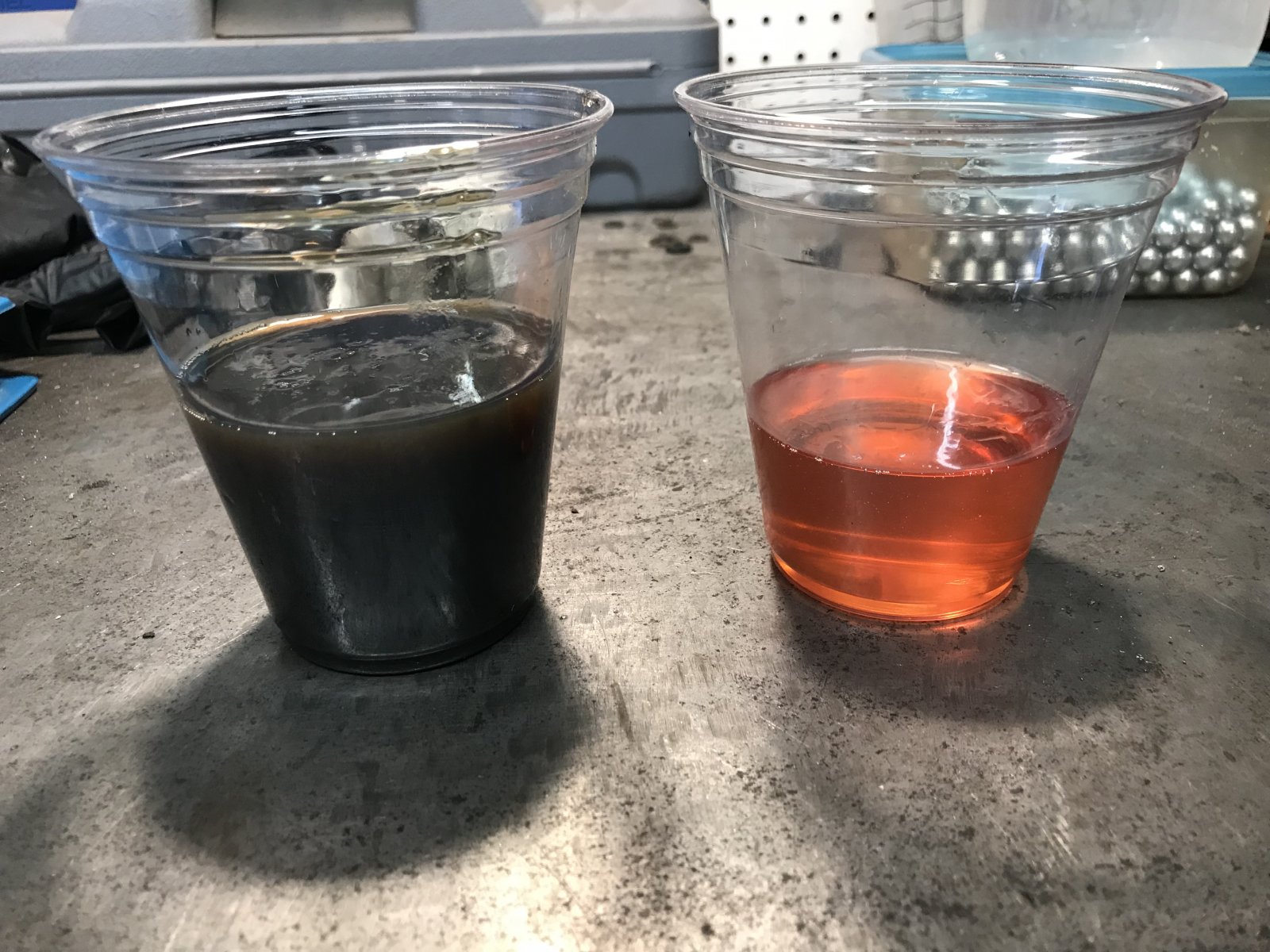

Decided to treat the trans with some good stuff. It deserves love too

Ben Louis

True Classic

The amazing part of it to me is how you are able to take so many photos, write up all the descriptions, and post it all. Often I think about trying to do this but I barely have time to do any actual work on my cars, let alone all the media stuff. Guess in part it might be a function of our generations; we did not grow up constantly holding a phone camera and taking pictures of ourselves/food/friends/pretty much nothing all the time and posting it on social media. We were too busy getting on with real life to sit around telling the world about it.

But seriously, nice work, keep it up.

Even though Im very computer/tech savy believe it or not Im not a huge picture/post/ social media guy. Personally I boycott most social media so I have no use for 1000 duck faced selfies. My personal belief is that tech these days can equally be a tool as much as a distraction/escape. I find little satisfaction in what many of my generation find post worthy. Plus as buddhists say reality is in the present moment. K rant concluded...

When doing work like this I quite often stop and think before going forward. This is a great time to snap pics! Then when I reach a point where things slow down I post.

Last edited:

lookforjoe

True Classic

I also think it would be better if you dropped the strut below the rail line as Karl suggested, that way you can add a floor pan back in to the trunk. Trimming that lip to allow a longer bolt to pass through is a better path, IMO.

I'm no spring chicken, however taking pics is an integral part of the process for me, most times. It's mostly a practical thing - makes it easier for me to keep track of what I've done. Smart phones made that process a whole lot easier. Drawings and pics work better than a written log, although I do often do that as well.

I'm no spring chicken, however taking pics is an integral part of the process for me, most times. It's mostly a practical thing - makes it easier for me to keep track of what I've done. Smart phones made that process a whole lot easier. Drawings and pics work better than a written log, although I do often do that as well.

Ben Louis

True Classic

Put the exhaust hanger on pause because I want to be able to test it out before finishing it up. Or maybe adapt it to fit between the rails. Well see, but that means I have to drive the car and the trans has been neglected for too long already.

This is how my drain plug looked when pulled. Do these come factory with a magnet because mine has one, nice surprise.

I went through the crud and these are the only pieces of metal of significance I found.

Old vs new

Research on Xweb helped me figure out filling procedure. I measured what drained out and what I put in: 2.5qts out 3.5 back in.

This is how my drain plug looked when pulled. Do these come factory with a magnet because mine has one, nice surprise.

I went through the crud and these are the only pieces of metal of significance I found.

Old vs new

Research on Xweb helped me figure out filling procedure. I measured what drained out and what I put in: 2.5qts out 3.5 back in.

kmead

Old enough to know better

Congrats on the drive, getting out and enjoying the fruits of your labor is wonderful thing.

I would say that once the car has been chewed up that much that adding a few holes to hold a bracket/brace in would be a relatively minor issue.

I am with Hussein: Unless you have other plans for the trunk, getting a floor back in there, impeding the view of that lovely exhaust system, would be of value.

Creating a brace to hold the exhaust up would still be needed as a floor isn’t a good way to carry the load across there. The two could be integrated, basically a flat floor panel with a hat channel underneath to carry the loads from the exhaust system. A layer of mineral wool with a sheet of stainless steel floating below with an air gap would serve to minimize heat transfer.

In any case great work and thanks for bringing us along.

I think your design is actually a better solution overall. I considered it first actually, though less well developed than yours. Problem is that the bolts on the inner face of the rail dont go all the way through. There is a metal lip that just impedes using the threads from that direction and enabling a flat face to mount to. Considering how unceremoniously material has already been removed from the back end I just couldnt bring myself to cut anymore esp at the frame rail. Admittedly my solution is a work around. But I tend to be one of those “nothing is ever finished” types so I may come back and redesign again at some point.

View attachment 12208

I would say that once the car has been chewed up that much that adding a few holes to hold a bracket/brace in would be a relatively minor issue.

I am with Hussein: Unless you have other plans for the trunk, getting a floor back in there, impeding the view of that lovely exhaust system, would be of value.

Creating a brace to hold the exhaust up would still be needed as a floor isn’t a good way to carry the load across there. The two could be integrated, basically a flat floor panel with a hat channel underneath to carry the loads from the exhaust system. A layer of mineral wool with a sheet of stainless steel floating below with an air gap would serve to minimize heat transfer.

In any case great work and thanks for bringing us along.

carl

True Classic

I went through the same thought process you did to hang my exhaust but decided a cross brace was more complicated than I needed to just hang a turbo muffler from the header. As you can see I just use a simple exhaust hanger strap bolted to the back panel and a tab I welded on the exhaust pipe.

Attachments

Ben Louis

True Classic

So I recently went through a move and rummaged through all my parts. Found this panel which seems to fit in the trunk.

So in addition to comments here I felt like ok now I have to inset the exhaust hanger within the frame rails.

So here we go with the angle grinder

33 year old seam sealer. This stuff was a real pita to remove

Similar but different

So in addition to comments here I felt like ok now I have to inset the exhaust hanger within the frame rails.

So here we go with the angle grinder

33 year old seam sealer. This stuff was a real pita to remove

Similar but different

Ben Louis

True Classic

I reused the plate I had used for the original only flipped which left some visible holes on top. They dont look too pretty but it did allow me to use a stock hanger spring to support the far end of the muffler which so far seems to be a better solution than a rubber isolator at that end.

![IMG_0270[1].JPG](/forum/data/attachments/12/12255-437a814b56921d84180e91d64420a04f.jpg)