lookforjoe

True Classic

Spent time on the car this weekend, cleaning up odds & ends on my list.

Re-covered the accessory gauge panel with a thinner vinyl leatherette - the original one I made was too 'thick" & just didn't look right (no pic)

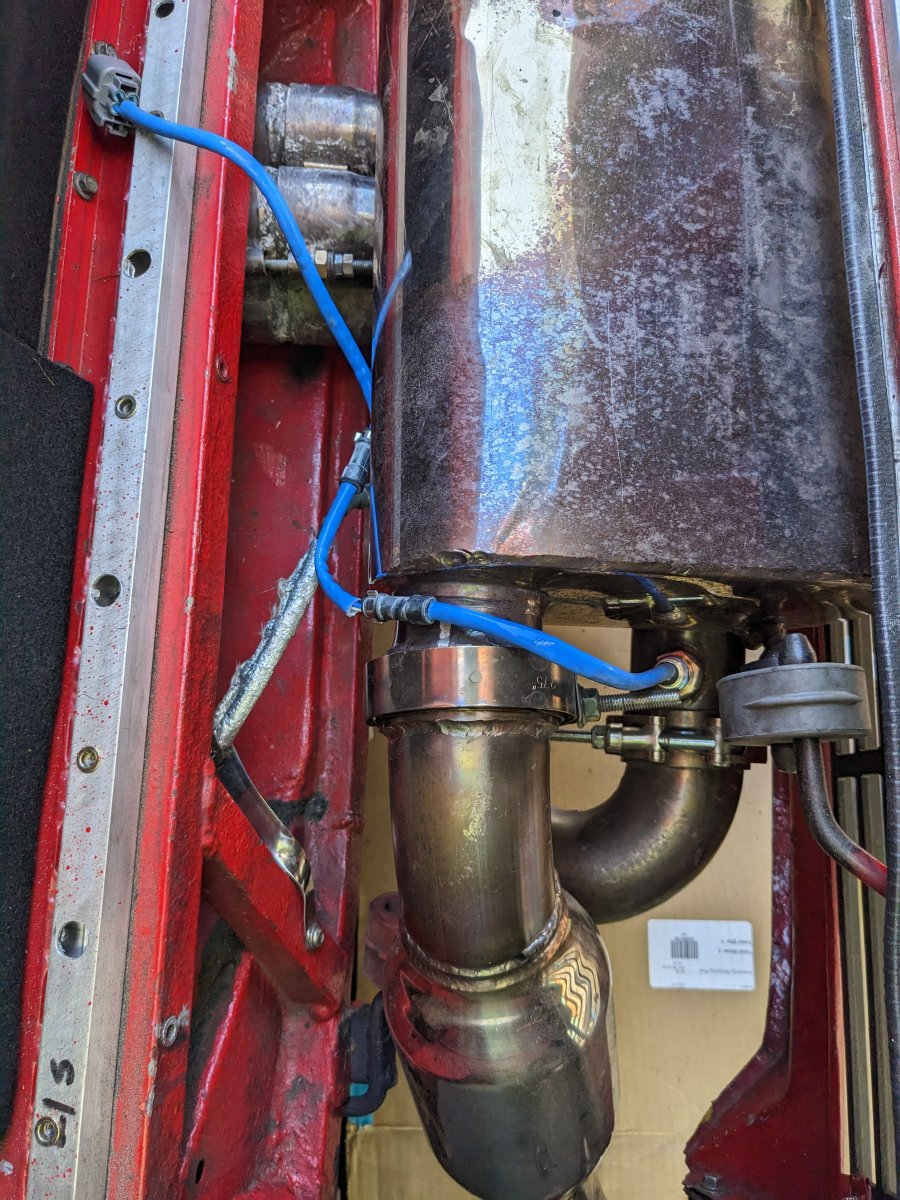

Got an O2 failure code on Friday (P1157), so I removed the trunk panel (again) and replaced it with a New Denso unit 234-9066

Removed the Dalla wing, and compounded & polished the trunk lid. I had not done a perfect job last year when I installed it

Re-covered the accessory gauge panel with a thinner vinyl leatherette - the original one I made was too 'thick" & just didn't look right (no pic)

Got an O2 failure code on Friday (P1157), so I removed the trunk panel (again) and replaced it with a New Denso unit 234-9066

Removed the Dalla wing, and compounded & polished the trunk lid. I had not done a perfect job last year when I installed it