One thing that I found worked well for me. Hit it with a blow torch for a few seconds. Not long enough to burn it, but enough to get the rubber soft. Then work at it with the pliers @andreav linked to. The rubber underneath the metal sleeve has hardened and needs to be pliable for it to come off easy.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Removing the head

- Thread starter Tavalin

- Start date

Tavalin

Florida Mike (again)

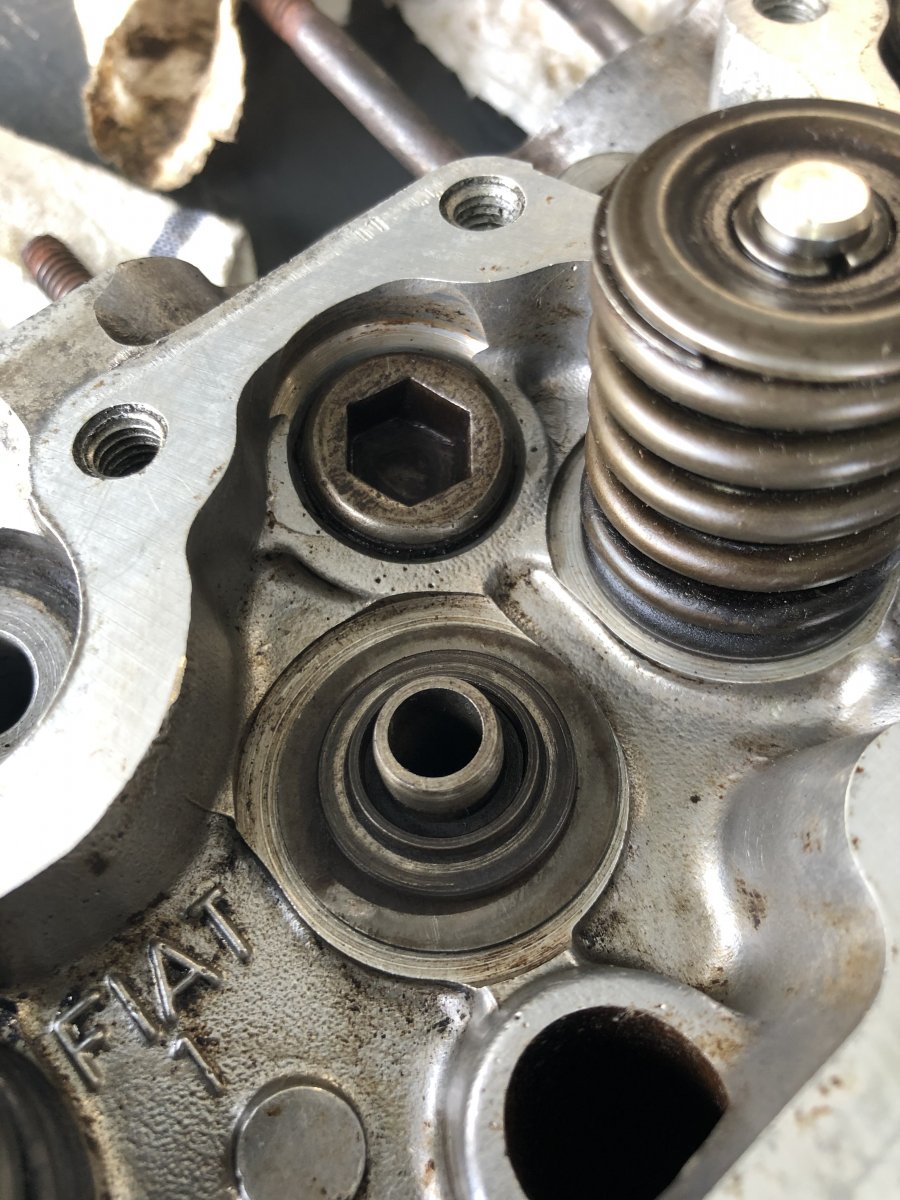

I did it!!! I was able to muster enough courage and worked out the seal that basically exploded into tiny pieces. Then on to the second one and it came out too easy. Stayed intact. Two is all the time I had today. I will get to the rest soon. Cleaning everything takes longer than taking the spring and seal out.

I am getting there... little by little. I am taking my time and asking when I don’t understand or need help. Everyone here is great!!! After this, the side engine mount and then reassembly. This will be fun... finding where everything goes back...lol

Enjoy the pics...

Mike

I am getting there... little by little. I am taking my time and asking when I don’t understand or need help. Everyone here is great!!! After this, the side engine mount and then reassembly. This will be fun... finding where everything goes back...lol

Enjoy the pics...

Mike

Rod Midkiff

True Classic

cool. Love the detail pictures!!

Tavalin

Florida Mike (again)

I am finally finished with the head. All valve seals replace and dirt and junk gone.

That took a lot longer than I wanted but it is the holidays.

I used a 12mm deep well socket and a rubber mallet to seat the valve seal. Cleaning everything up took the longest.

Anyway, it is done and I did it myself with all of your advice and mentorship, thanks. I am almost a master Fiat mechanic...lol (NOT!!!).

Anyway, the engine mount and cam seal left to go and then the reassembly starts.

Mike

That took a lot longer than I wanted but it is the holidays.

I used a 12mm deep well socket and a rubber mallet to seat the valve seal. Cleaning everything up took the longest.

Anyway, it is done and I did it myself with all of your advice and mentorship, thanks. I am almost a master Fiat mechanic...lol (NOT!!!).

Anyway, the engine mount and cam seal left to go and then the reassembly starts.

Mike

Tavalin

Florida Mike (again)

Now, after I figure out how to take out the engine mount I am going to tackle the cam seal. I see that there is a small pin that holds something.

Question is; what do I need to know on how to take the cam seal out? I have the valve box off and the cam just moves. I don’t know a safe way to hold it. Any suggestions will be greatly appreciated.

Now, the engine mount turned out to be tougher than expected. I have to take out the water pump to get to the middle bolt, crazy. I will have that completed sometime in May 2026..lol

Getting there little by little.

Mike

Question is; what do I need to know on how to take the cam seal out? I have the valve box off and the cam just moves. I don’t know a safe way to hold it. Any suggestions will be greatly appreciated.

Now, the engine mount turned out to be tougher than expected. I have to take out the water pump to get to the middle bolt, crazy. I will have that completed sometime in May 2026..lol

Getting there little by little.

Mike

Tavalin

Florida Mike (again)

I am now going to tackle the cam seal. I see that there is a small pin that holds something.

Question is; what do I need to know on how to take the cam seal out? I have the valve box off and the cam just moves. I don’t know a safe way to hold it. Any suggestions will be greatly appreciated.

Now, the engine mount turned out to be tougher than expected. I have to take out the water pump to get to the middle bolt, crazy. I will have that completed sometime in May 2026..lol

I have also installed the head and torqued down the bolts per the service manual and the torque settings from MWB. Going to continue with the installation.

I need to replace the cam seal now and then continue the reassembly.

Getting there little by little.

Mike

Question is; what do I need to know on how to take the cam seal out? I have the valve box off and the cam just moves. I don’t know a safe way to hold it. Any suggestions will be greatly appreciated.

Now, the engine mount turned out to be tougher than expected. I have to take out the water pump to get to the middle bolt, crazy. I will have that completed sometime in May 2026..lol

I have also installed the head and torqued down the bolts per the service manual and the torque settings from MWB. Going to continue with the installation.

I need to replace the cam seal now and then continue the reassembly.

Getting there little by little.

Mike

Tavalin

Florida Mike (again)

Interesting tool. Looks like modified pliers. Really cool, thanks for sharing.View attachment 28215 View attachment 28217 View attachment 28218

A little late here but I made a set of stem seal removers after screwing up more than one set and multiple tries. Just enough taken out to apply a decent amount of pressure View attachment 28215 View attachment 28217 View attachment 28218

Mike

dcioccarelli

Dominic Cioccarelli

View attachment 28215 View attachment 28217 View attachment 28218

A little late here but I made a set of stem seal removers after screwing up more than one set and multiple tries. Just enough taken out to apply a decent amount of pressure View attachment 28215 View attachment 28217 View attachment 28218

Very nice

For those without your fabrication skills:

https://www.joom.com/en/products/5c2475388b2c37010148774b

Cheers,

Dom.

Tavalin

Florida Mike (again)

Update

I have officially started the reassembly!!! I have some new hoses installed and the exhaust manifold and intake runners installed. There was a stud with a bolt welded to the stud being used for one of the bolts on the exhaust manifold. Going to get new bolts and washer to complete the install.

I will try and tackle the cam seal with the valve box is back on. Can’t seem to break the nut free on the pulley with it off.

Well, slowly but surely I will get the X back together again.

Mike

Happy New Year Everybody!!!!

I have officially started the reassembly!!! I have some new hoses installed and the exhaust manifold and intake runners installed. There was a stud with a bolt welded to the stud being used for one of the bolts on the exhaust manifold. Going to get new bolts and washer to complete the install.

I will try and tackle the cam seal with the valve box is back on. Can’t seem to break the nut free on the pulley with it off.

Well, slowly but surely I will get the X back together again.

Mike

Happy New Year Everybody!!!!

I will try and tackle the cam seal with the valve box is back on. Can’t seem to break the nut free on the pulley with it off.

Have you tried using the old belt as primitive "strap wrench" to hold the cam pulley wheel you try to break the nut free? There is also a Fiat tool for holding the cam wheel in place, but that would take some effort to get.

Tavalin

Florida Mike (again)

JimD,

I will pull out an old belt and try that method. However, I am not really sure how to do that. I am thinking it would be easier. I just don’t really know. Going to ponder on it and see if my meds work and I think of something.

Sure would be nice to have that taken care of. I did notice that several valve seals could have been leaking. I don’t want the same for the cam.

Thanks,

Mike

I will pull out an old belt and try that method. However, I am not really sure how to do that. I am thinking it would be easier. I just don’t really know. Going to ponder on it and see if my meds work and I think of something.

Sure would be nice to have that taken care of. I did notice that several valve seals could have been leaking. I don’t want the same for the cam.

Thanks,

Mike

Well you could install the old belt, but I was thinking more like wrapping the belt around the cam wheel only, engaging the teeth. Maybe put a few twists in the belt to snug it to the pulley, then hang onto the belt while wrenching and see if that gives you the leverage you need to break the nut loose. I think the torque spec on that cam nut is 35 ft lbs. I could be wrong.JimD,

I will pull out an old belt and try that method. However, I am not really sure how to do that. I am thinking it would be easier. I just don’t really know. Going to ponder on it and see if my meds work and I think of something.

Sure would be nice to have that taken care of. I did notice that several valve seals could have been leaking. I don’t want the same for the cam.

Thanks,

Mike

Dan Sarandrea (Phila)

Waitin' On Parts...

Assuming you took the head to a machine shop for evaluation, take the cambox back to the same place and ask them nicely if they would break the cam cog wheel capscrew loose with their air gun. Might require buying them a round of coffees.

Or any repair shop with an air gun would work, too.

Or any repair shop with an air gun would work, too.

Tavalin

Florida Mike (again)

Dan,Assuming you took the head to a machine shop for evaluation, take the cambox back to the same place and ask them nicely if they would break the cam cog wheel capscrew loose with their air gun. Might require buying them a round of coffees.

Or any repair shop with an air gun would work, too.

Didn’t think about that. I will try the old belt method first then your suggestion.

Happy New Year,

Mike

ghostdancing

True Classic

Mike your exhaust manifold looks not so beautiful..i would have a better\new one

Mike your exhaust manifold looks not so beautiful..i would have a better\new one

Or at a minimum find the heatshield for it. That will help increase the longevity of your fuel injectors/rubber fuel lines.

Tavalin

Florida Mike (again)

aarpcard,Or at a minimum find the heatshield for it. That will help increase the longevity of your fuel injectors/rubber fuel lines.

Thanks for the reminder.

I have it... I just need to install a couple of exhaust Mansfield bolts (10mm head type). One was a stud with a nut welded to it. So I picked up the correct bolt and will install it this weekend along with the heat shield.

Now, to redo a couple of hoses with correct length hoses and new hose clamps change out one or two fuel injector hose clamps that I dorked up when I installed the new injectors then on to the rear lower radiator hoses and connect them to the thermostat housing. Then just keep moving forward.

In between, I will be working on the cam seal.

Still a lot to do but getting there very methodically and taking my time (which I am not known for).

Thank for ensuring I remembered. Keep checking up on me to ensure I stay on track and don’t forget something that will cause me to rant and throw my tools out into the street.

Mike

Mike,

The seals are a press fit and the old one coming out has no reuse potential. I suppose you have a new one in hand so you can examine it prior to destroying the old one... right? Look the new one over and you will see it is basically an empty channel holding a V seal. There is a stretchy band inside the V seal to keep it in shape. If you don't have an official seal puller tool (there are a variety), you can carefully drive the tip of a small flat blade screw driver thru the wide flat back of the seal. Then use the screw driver and the hole you just created to pry the old seal out.

Lube the exposed cam shaft with motor oil, do the same for the surfaces of the new seal. Tap the new seal in using a proper diameter socket as a tool. If the inner V seal section tries to roll up on the cam shaft rather than slip over it.... STOP. Wiggle the seal back off and add some more oil to all surfaces in contact with each other.

The seals are a press fit and the old one coming out has no reuse potential. I suppose you have a new one in hand so you can examine it prior to destroying the old one... right? Look the new one over and you will see it is basically an empty channel holding a V seal. There is a stretchy band inside the V seal to keep it in shape. If you don't have an official seal puller tool (there are a variety), you can carefully drive the tip of a small flat blade screw driver thru the wide flat back of the seal. Then use the screw driver and the hole you just created to pry the old seal out.

Lube the exposed cam shaft with motor oil, do the same for the surfaces of the new seal. Tap the new seal in using a proper diameter socket as a tool. If the inner V seal section tries to roll up on the cam shaft rather than slip over it.... STOP. Wiggle the seal back off and add some more oil to all surfaces in contact with each other.