Cooling system, Part 1.

The cooling system plumbing routing for the K20 swap is probably one of the more variable aspects of this build, probably because the swap kit from MWB does not come with any parts related to the cooling system. So, it is pretty much up to the individual building it as to how they do it. I have looked at pictures of different swaps to see how each one was done and I had a chance to study in person, Roobus’s swap that was done by MWB. There is a lot of plumbing that all comes together in a very small space under the intake manifold, since the water pump intake and the underbody cooling tubes and heater supply tube are all next to each other right below it. I will do my best to describe my thinking about the parts I used for mine. I apologize if it rambles a bit, but I figured that at least it will give others out there some insights into at least one way to do it.

All of the swaps that I have seen delete the stock thermostat housing as it takes up a lot of space and doesn’t really point in the right direction to meet up with the under-body cooling tubes very well.

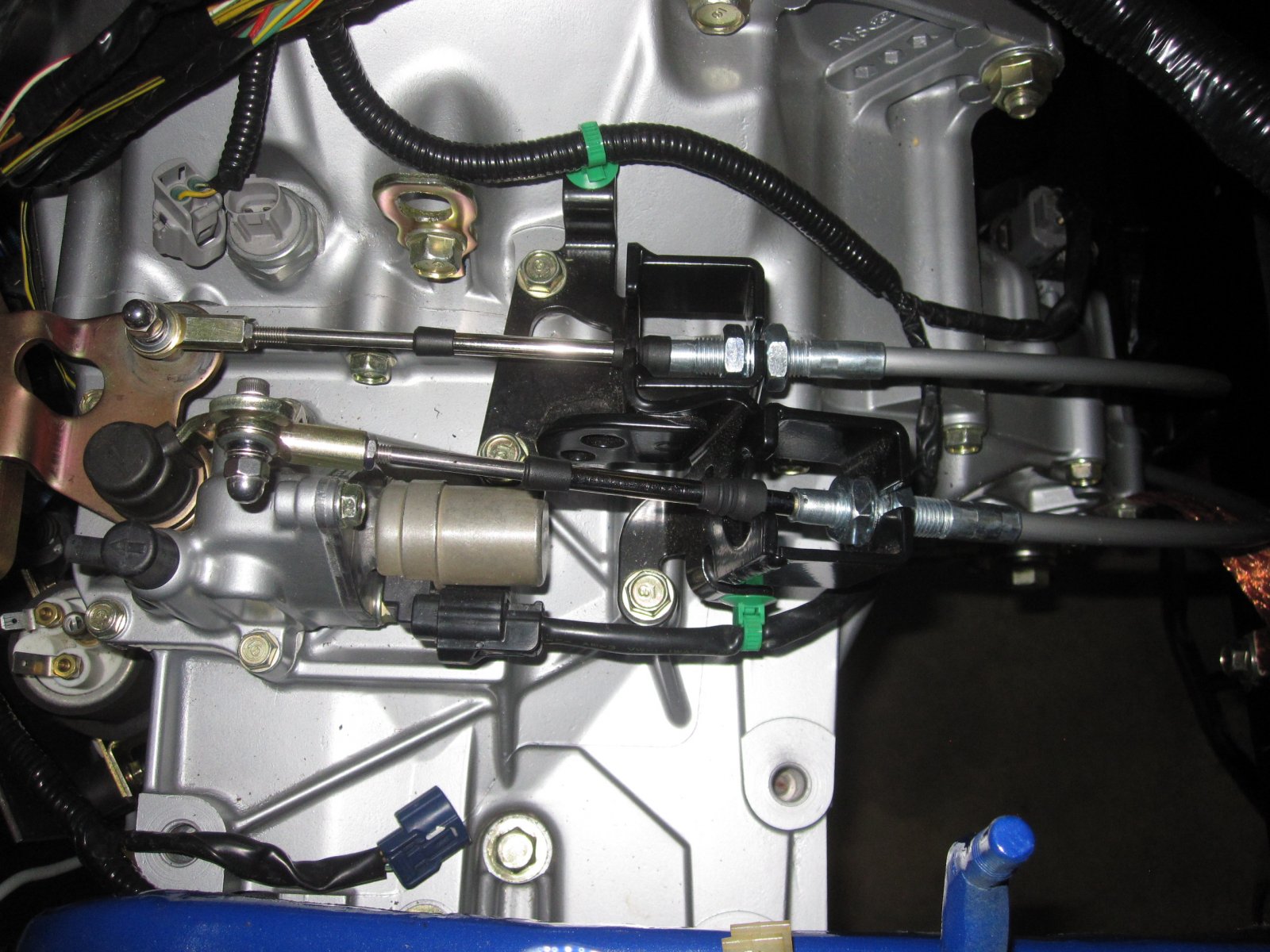

The MWB swaps I’ve seen use a custom made plate with an inlet to replace the thermostat housing on the water pump. They used an external thermostat from a Lancia that allows for recirculation of the coolant until the engine warms up. It seems like there are a few different styles of external thermostats which influences the way the plumbing would go depending on the direction of the connections. MWB also did some extensive welding fabrication to modify the stock upper coolant housing from the cylinder head to redirect the flow to go under the intake manifold to the external thermostat and then to the cooling tubes. These pictures are from Roobus's swap.

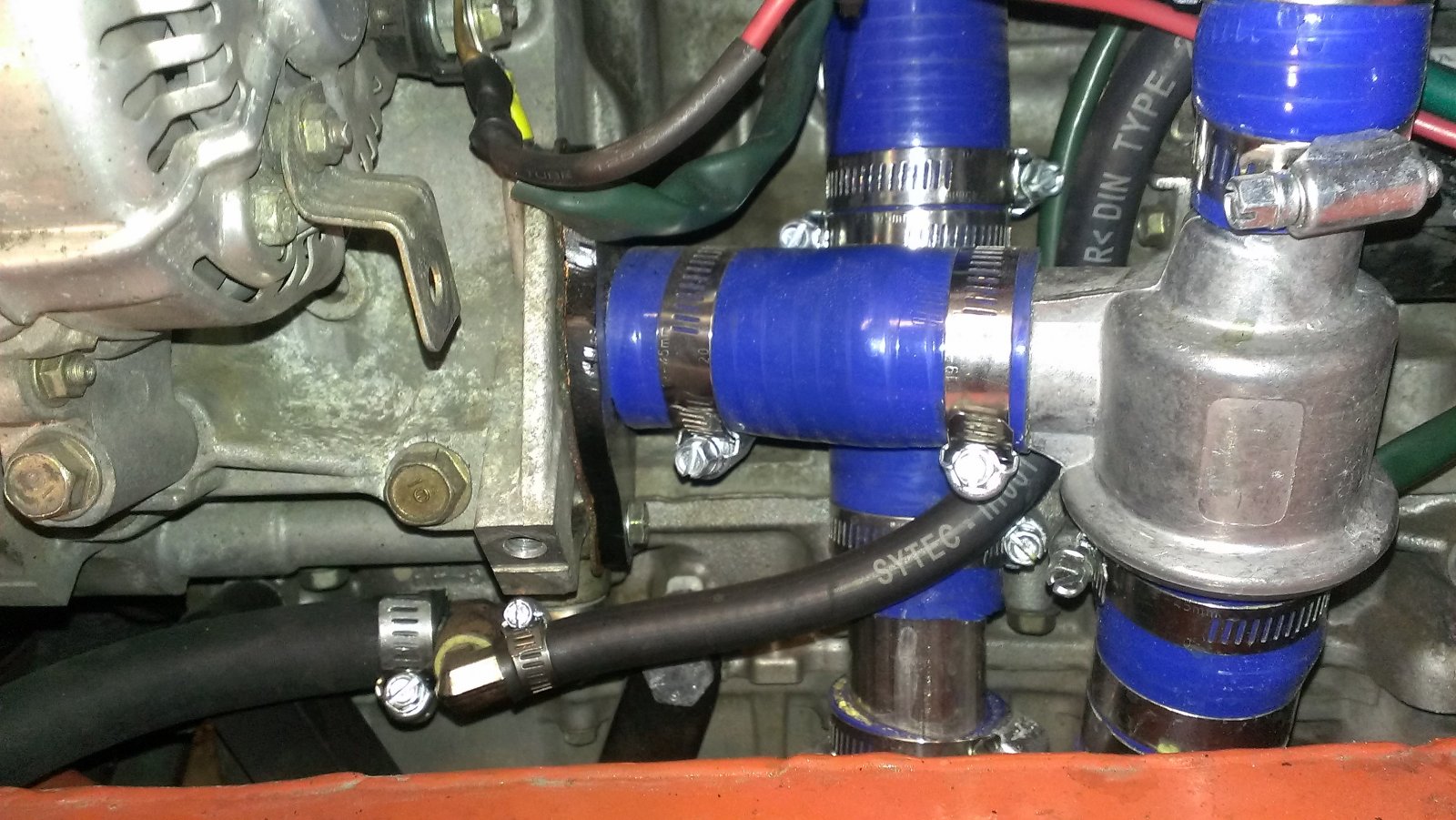

K-Tuned is an outfit that built their business around K20A2 swaps (mostly into other Hondas) and makes quite an assortment of very nice machined parts. They make an upper coolant housing with many different configuration options. They also have a swivel neck thermostat housing to replace the stock one which gets it much closer to the water pump as well as allowing for an infinite variety of directions for the inlet. This housing also has an inlet for the recirculation circuit that gets deleted with removal of the stock thermostat housing. I decided to try and use the K-Tuned parts instead of trying to have someone weld up something custom for me. Since I was using an external thermostat, I just left the thermostat out of the housing since it is only a single action thermostat as opposed to the double action of the external Lancia one.

As I was designing my approach, there are several circuits that have to be considered. There is the recirculation circuit from the cylinder head to the thermostat and then to the water pump until the engine warms up enough for the thermostat to open and allow the coolant from the radiator to flow to the water pump. There is the main flow from the cylinder head to the radiator than back to the thermostat and on to the water pump. There is the heater supply from the cylinder head to the heater core, then back to the water pump. There is the supply and return from the coolant reservoir tank. There was good discussion about this in this thread.

https://xwebforums.com/forum/index.php?threads/just-started-my-k20-project.26527/ I used the same basic cooling system routing as on Roobus’s X as diagramed by Pete Whitstone, which is pretty much how the stock X1/9 cooling system works. Here is my version of Pete’s diagram.

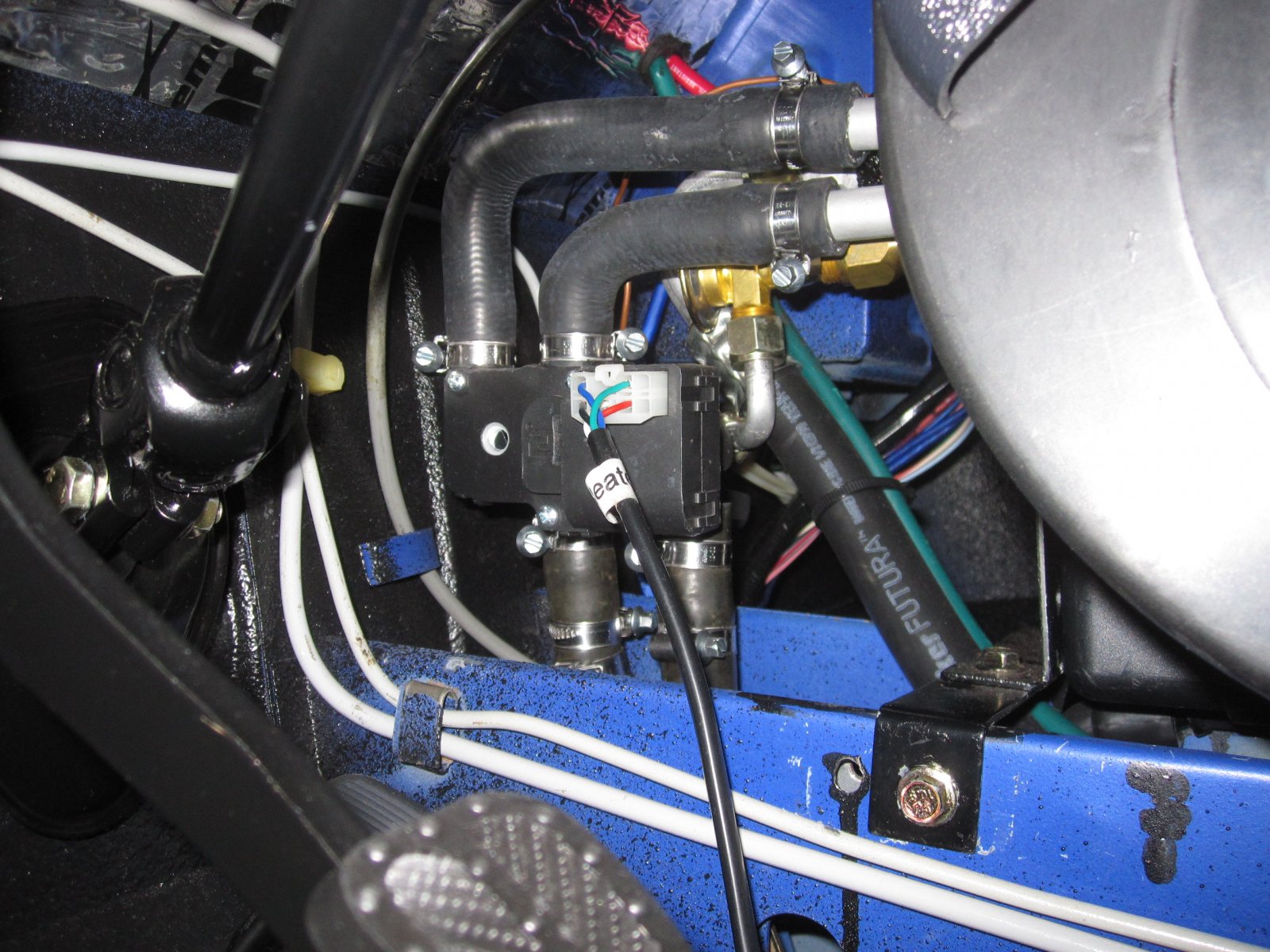

One thing that is unique to my build is the aftermarket air conditioning system that has a mixing valve to control the temperature of the heater core. Unlike the stock system that has a simple valve that just increases or decreases the flow to the core, the valve for the Hurricane system that I used has four connections to it, two from the engine and two to the heater core, so I assume that there is coolant flowing through the valve continuously.

As you move the temperature rheostat slide towards hot, it diverts it to the heater core so there is probably an instant response since you don’t have to wait for the hot coolant to come all the way from the engine as with the stock set-up.

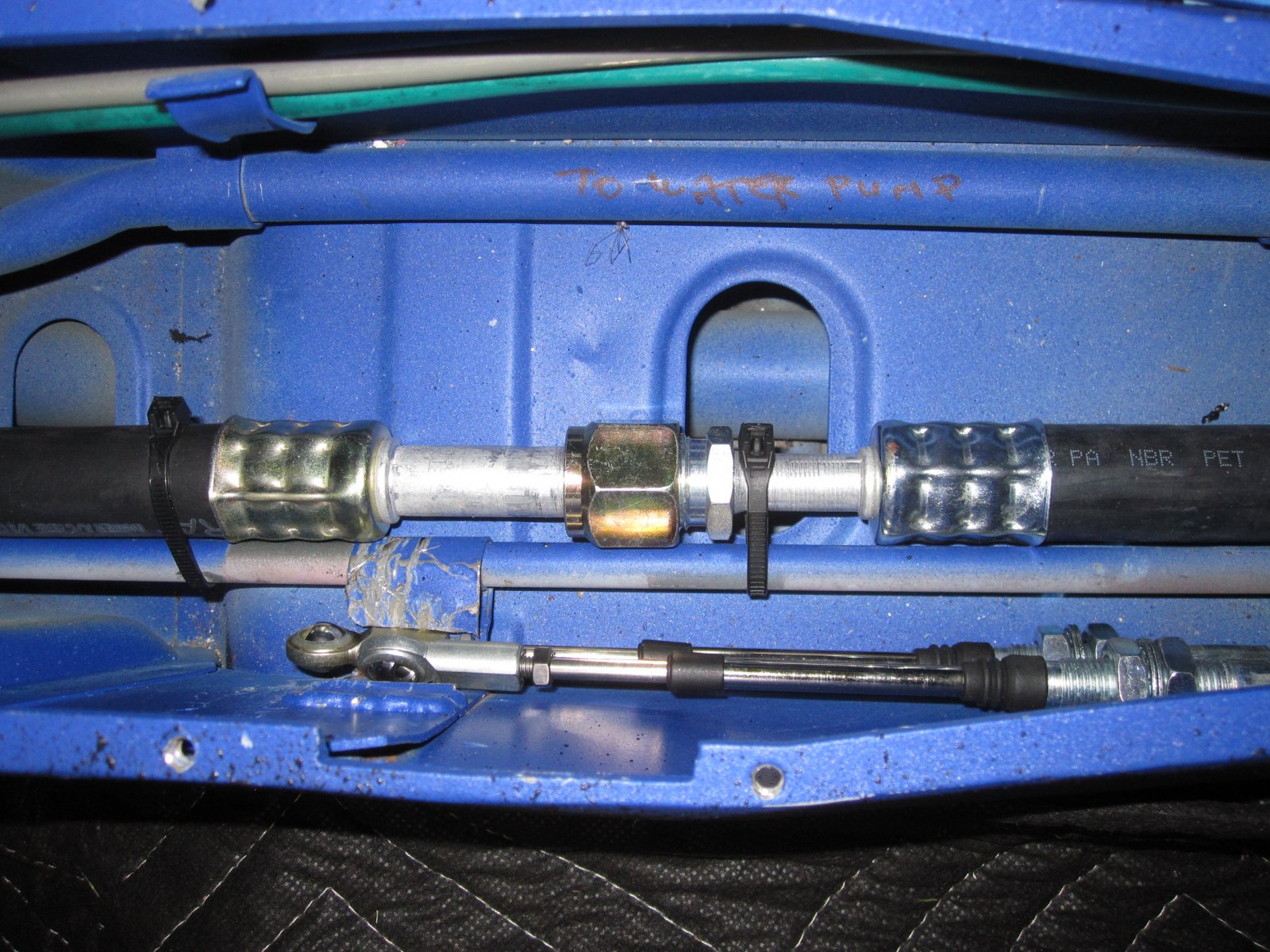

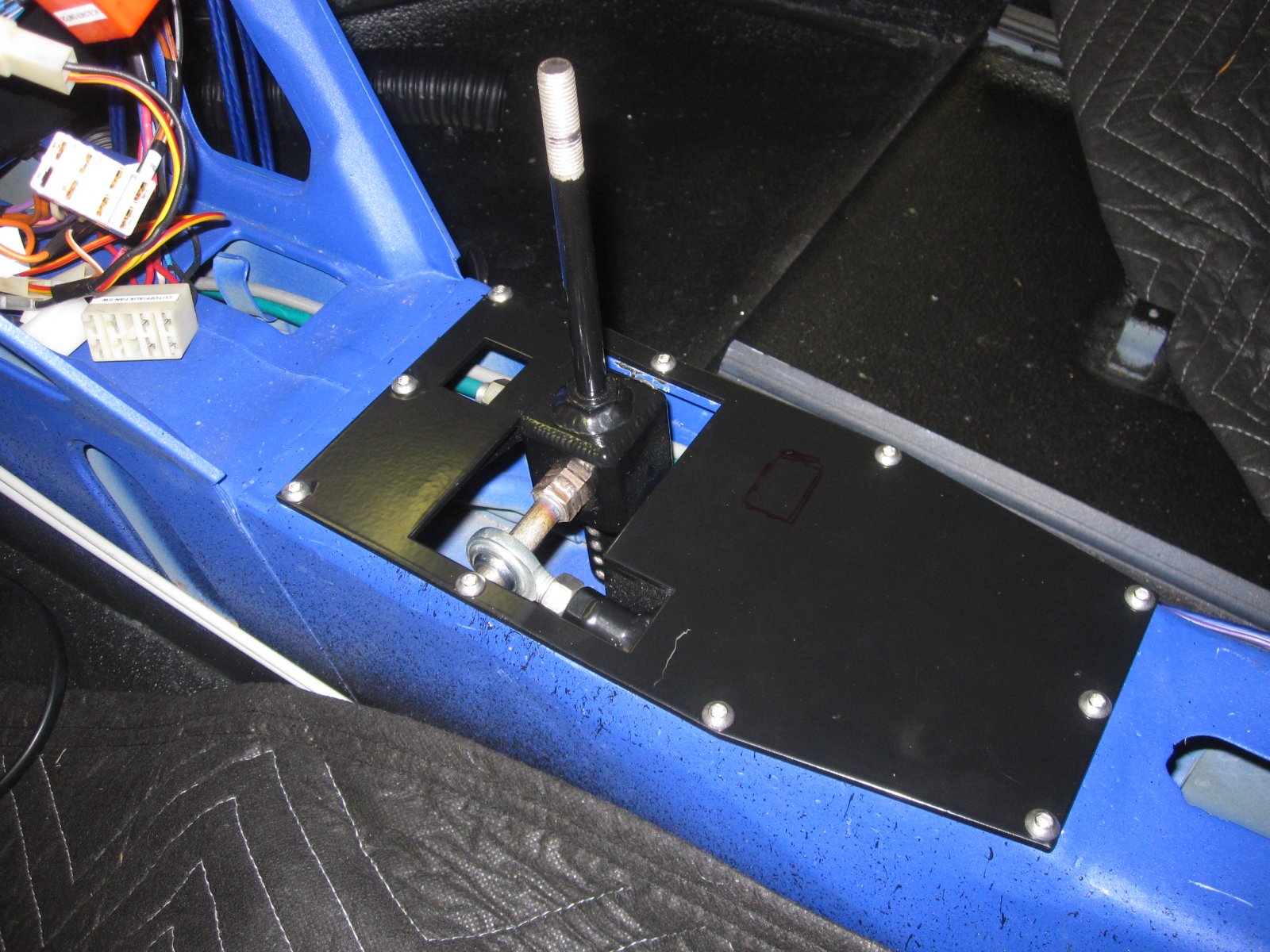

Anyway, the way it worked out to fit the valve in the tight space behind the evaporator unit, the flow through the body pipes ended up being backwards from stock. The pipe that runs through the shifter tunnel needs to be connected to the water pump inlet, whereas the stock set-up has that pipe carrying the hot water from the cylinder head. My connection from the cylinder head goes to the underbody pipe that comes up through the floor pan into the tunnel under the heater core. Also, the hose that normally runs from cylinder head through the firewall, then through the spare tire well and then into the tunnel is deleted since I have the access box and subwoofer in the spare tire well. I just ran the hose from the pipe in the shift tunnel straight out the hole in the cover plate that has the parking brake pulleys, along with the shift cables. This hole was used for the shift rod to the transmission in the stock application.

The stock K20A2 recirculation circuit comes off the cylinder head outlet on the intake side of the engine. This same housing is also the large outlet to the radiator. The recirculation circuit is the angled hose heading under the intake manifold then to the thermostat housing.

The outlet for the heater core comes off the cylinder head on the exhaust side of the engine. This circuit then goes through the firewall to the heater core, then back out to connect to a ¾” pipe which runs along the back of the engine then bends around to go under the intake manifold and connects to the thermostat housing. There are a couple of small water take offs on this pipe that feed some of the temperature related items that are not needed for the swap. Although the main/recirculation outlet and the heater outlet are on opposite sides of the cylinder head, they are both connected to the large common cooling space in that end of the cylinder head.

I decided to use the heater outlet pipe for the recirculation circuit since it is closer in size to the 1" inlet of the thermostat. I connected a 180-degree bend hose to go from the outlet right back to the ¾” pipe.

I cut off part of the heater outlet pipe to make the bend shorter. I cut off the small take off under the cam position sensors and closed it with a piece of hose clamped over the hole. Not very elegant, I will admit. I cut the pipe before it made the final bend to the thermostat so that it ends under the intake manifold. I didn't get any good pictures of just the pipe before more things got laid on top of it.

Continued in the next post as Xweb will only allow 10 photos per post.