lookforjoe

True Classic

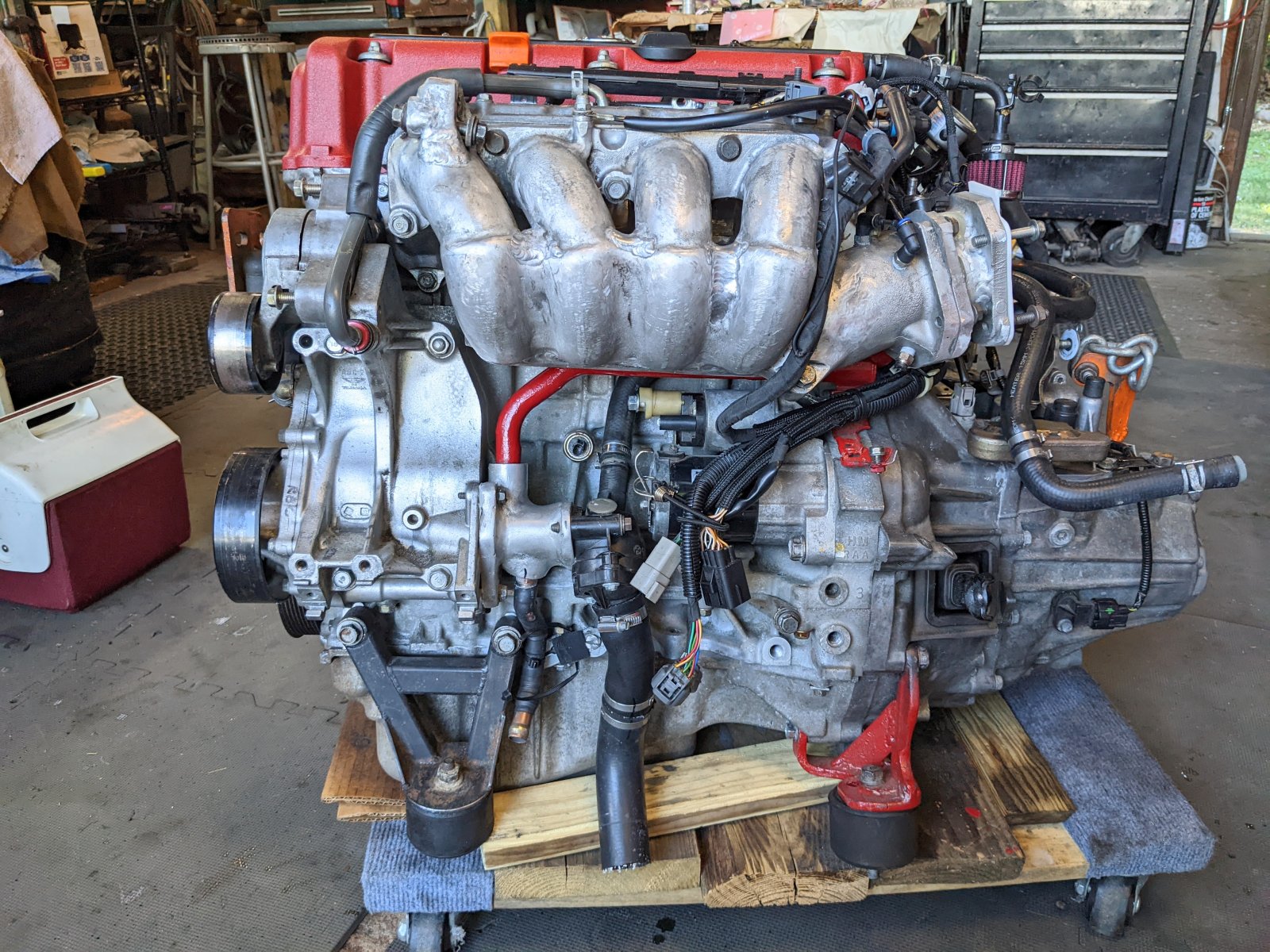

After that, I started to put the drivetrain back in. I'll finish that today

Left out the water feed pipe, otherwise connecting the main power harness to alt, knock & starter is near impossible from the cabin side access. Also removed the AC related plates, as those make a significant difference to the height I have to elevate the chassis. TB is also left off. Alternator & belt are last items to go back in on cabin side. Subframe is NOT attached prior to placement, I find it much easier to focus on drivetrain placement without having to align the subframe mounts at the same time.

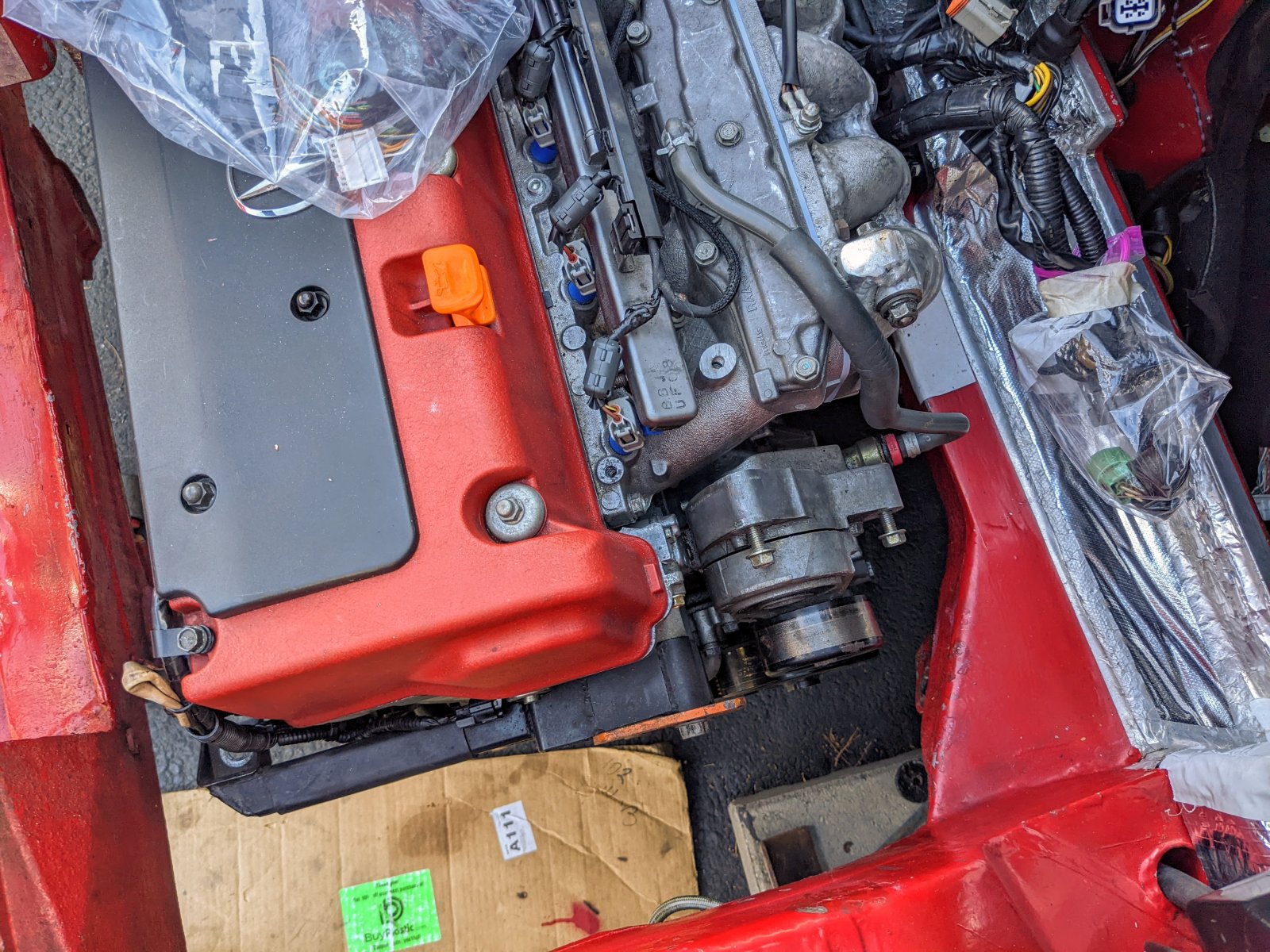

noting left side support bracket positioning to clear subframe

drivetrain set as far left as possible for 2/3 of the chassis lowering, dropped a few inches at a time, then check all sides for clearance before next drop....

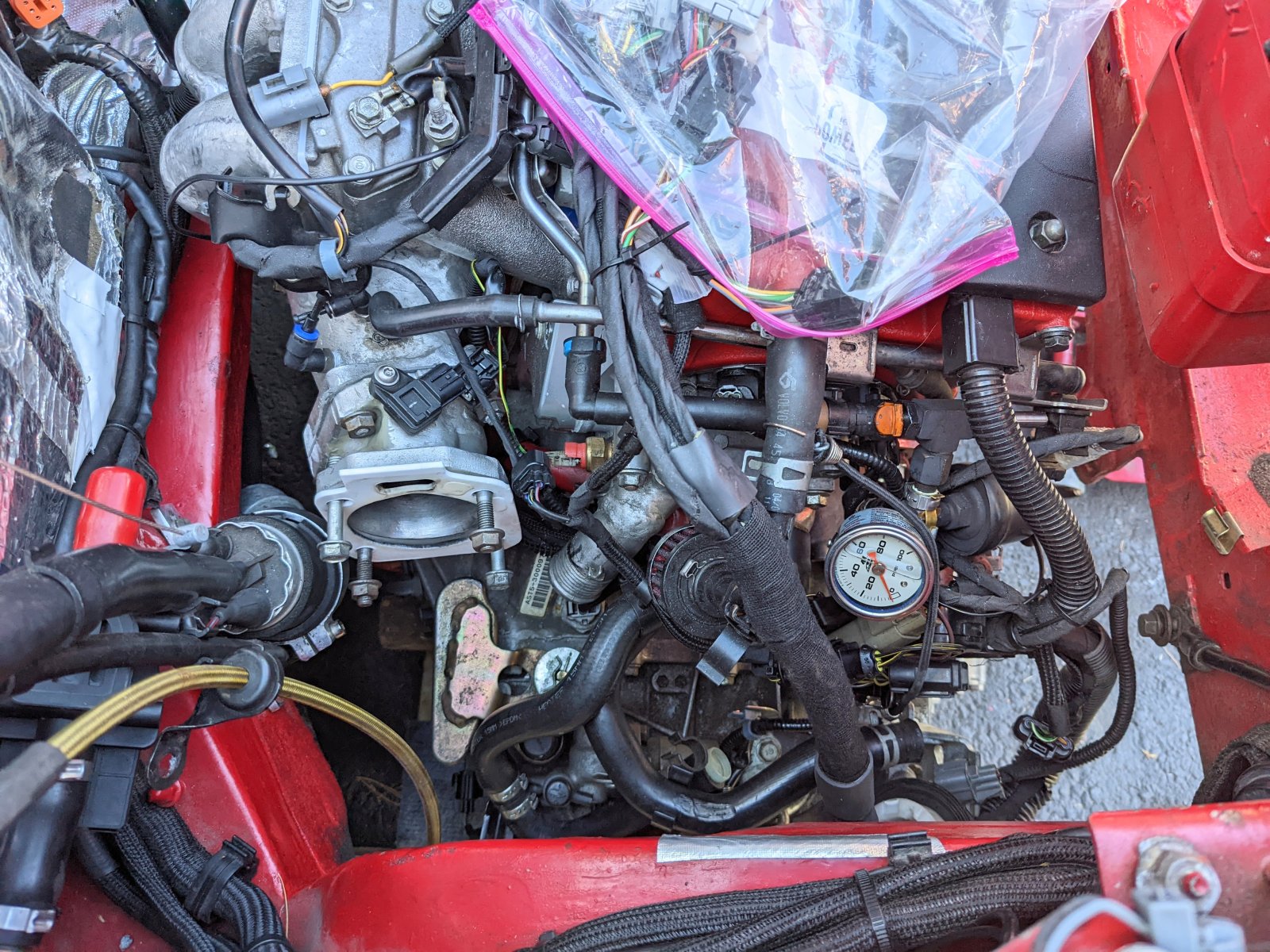

...then pushed to the right, drivetrain brace (Astro 5820) added (note, need to add markings for support rod positioning on crossbar), torque mount loosely installed to align drivetrain laterally, EMS harness set through rear bulkhead, clutch slave then heater feed hose, transaxle ground strap installed, chassis lifted & set back on jack stands

Left out the water feed pipe, otherwise connecting the main power harness to alt, knock & starter is near impossible from the cabin side access. Also removed the AC related plates, as those make a significant difference to the height I have to elevate the chassis. TB is also left off. Alternator & belt are last items to go back in on cabin side. Subframe is NOT attached prior to placement, I find it much easier to focus on drivetrain placement without having to align the subframe mounts at the same time.

noting left side support bracket positioning to clear subframe

drivetrain set as far left as possible for 2/3 of the chassis lowering, dropped a few inches at a time, then check all sides for clearance before next drop....

...then pushed to the right, drivetrain brace (Astro 5820) added (note, need to add markings for support rod positioning on crossbar), torque mount loosely installed to align drivetrain laterally, EMS harness set through rear bulkhead, clutch slave then heater feed hose, transaxle ground strap installed, chassis lifted & set back on jack stands

Last edited: