I took a little detour from working on the doors to tweak the exhaust. Although it was much better with the chambered muffler and resonator, it was still a bit louder than I would like. I had seen someone post about an exhaust insert here on the forum quite a while back, so I thought I might give that a try. I ordered a Car Chemistry one from Summit Racing.

https://www.summitracing.com/parts/cci-3di25r

The photos are of it after I already started whittling on it. I thought it was supposed to go in the tailpipe, but Car Chemistry says it is best inserted just after the collector of the exhaust header, ideally after the catalytic converter. Well, no way that can happen with the 180 degree bend between the cat and the muffler, so I decided to try after the header. I disconnected the exhaust at the V clamp and figured that I could get at least two of the rings in. The three ring version is for street cars, but they sell a two ring version for racing cars with no mufflers, so I figured two would be better than nothing. They also say that you can pack some muffler packing or stainless steel wool in between the rings if you want to quiet the exhaust down even more, but I didn't try that yet. Because they are designed to fit into a straight exhaust pipe, it wouldn't go past the V clamp flange as that had a slightly smaller ID. Plus the exhaust starts to curve soon after the clamp. I couldn't put it into the header side of the system because the O2 sensor was there. While I had it apart, I noted a slight exhaust leak at the clamp, even though it was very tight.

Here is the insert after I got done carving it down to fit into the exhaust.

I tapped a small hole for an M6 retaining bolt so it wouldn't get loose and start rattling.

I used a little high temp copper sealant on the V clamp to see if that would eliminate the small leak and put it all back together. I let the sealant set for 24 hours, then took it out for a drive. I felt that it did make enough of a difference in the sound level to bring it down to a better level for me, so I felt it was worth the effort.

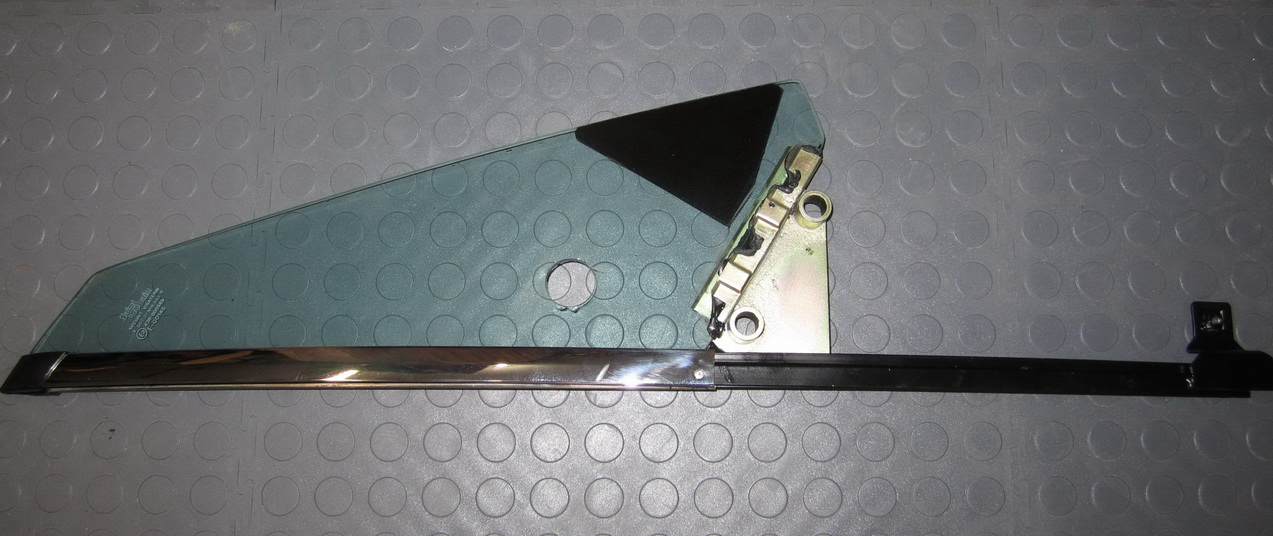

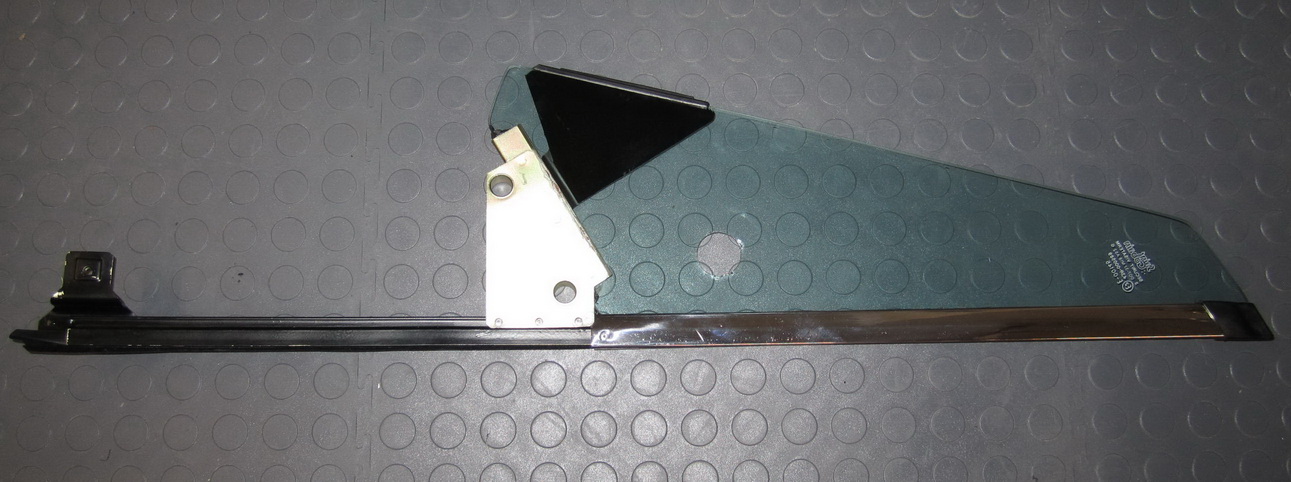

When I first got it, I thought I would try to put it in the tailpipe and see if that made any difference. To do that, I had to cut off the chrome tip that I had tack welded on. I found that it didn't seem to do much in the tailpipe, so that is why I put in after the header. One of the things that happened when I redid the exhaust system, is that the stick out of the chrome tip the second time, didn't seem as much and I thought it was a too short at that point. The tips came as a pair, so I still had one that was the original length as I had cut one down for my first go round. I put the original length one on and am trying to decide if I like the longer look or if I should shorten it some. Here are a couple of views of the new tip. I realize that car aesthetics are a personal thing, but thought I would get some opinions from the X crowd as to the length of the tip currently. Feel free to weigh in. This time I fixed it with a couple of set screws so it is easy to remove and modify.