You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

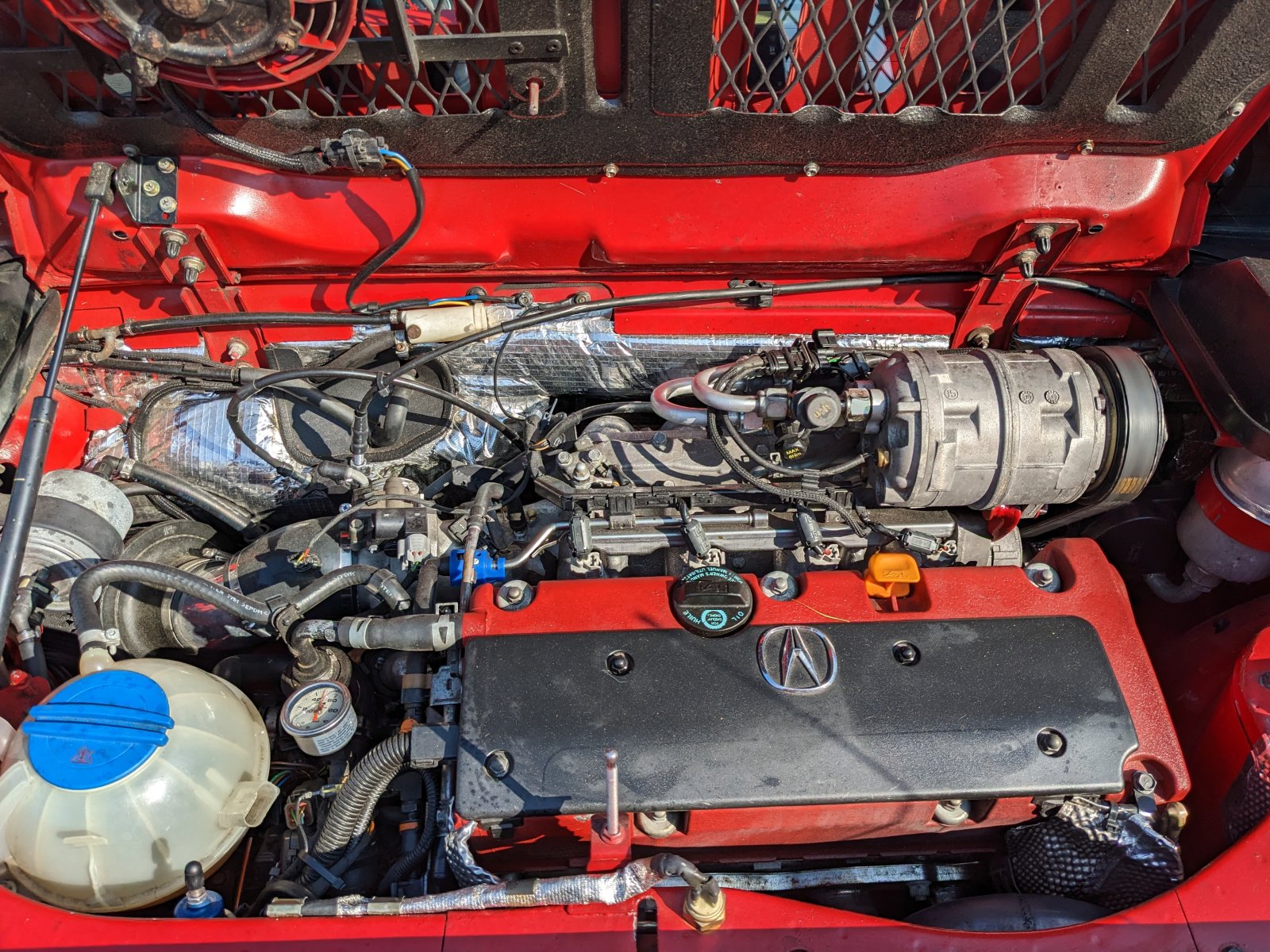

Performing Honda K24a3/AST5 6spd Conversion

- Thread starter lookforjoe

- Start date

lookforjoe

True Classic

So, it stopped raining & dried out enough that I could drive around a while to check the idle/rpm issue & listen to the exhaust.

It seems to be mostly resolved - it only seemed to hang on one or two occasions, and I can't be 100% on that since I removed the IACV restrictors as part of my testing. It good enough that I can drive it as is & see how it goes. The exhaust rattle/buzz is better, but not gone. Not sure there is any way I can stop the runners from resonating entirely.

I also took the time to finish wiring the eFan control wire from the tunnel out to the fan relay trigger. Now I can adjust the onset temp to match the engine temp, rather than the rad temp.

It seems to be mostly resolved - it only seemed to hang on one or two occasions, and I can't be 100% on that since I removed the IACV restrictors as part of my testing. It good enough that I can drive it as is & see how it goes. The exhaust rattle/buzz is better, but not gone. Not sure there is any way I can stop the runners from resonating entirely.

I also took the time to finish wiring the eFan control wire from the tunnel out to the fan relay trigger. Now I can adjust the onset temp to match the engine temp, rather than the rad temp.

Longitudinal

True Classic

Not sure there is any way I can stop the runners from resonating entirely.

Do have two primaries that are touching or nearly touching each other and buzzing when they resonate? If so, can you wedge some header wrap between them to stop the noise?

lookforjoe

True Classic

Do have two primaries that are touching or nearly touching each other and buzzing when they resonate? If so, can you wedge some header wrap between them to stop the noise?

That seems to be the case. I wedged SS plate in-between the 3 areas I found, so there must be other points of contact, I'll have to look further as it is annoying. Driving the car the past few days, the hang is still present. This is so f-king annoying. I'm going to gave to figure out a way to add an additional return spring to counter whatever the blasted system is doing to hold a partial throttle opening.

Last edited:

kmead

Old enough to know better

Rev hang has been one of the complaints about the K20 Si’s since the late 2000’s. Most current manuals suffer this for emissions reasons I suspect, the Tigershark in our Jeep Compass certainly does.That seems to be the case. I wedged SS plate in-between the 3 areas I found, so there must be other points of contact, I'll have to look further as it is annoying. Driving the car the past few days, the hang is still present. This is so f-king annoying. I'm going to gave to figure out a way to add an additional return spring to counter whatever the blasted system is doing to hold a partial throttle opening.

lookforjoe

True Classic

OK - played with adding an additional return spring yesterday. Drilled a hole in the inner wheel circumference, really no way to add a lever off the hub or wheels. This doesn't interfere with the cable, just another step if I need to remove it. Had to play with the height/offset/angle to get some pretension, and allow for proper extension over the 90º operating range. At full extension the edge of the outer coil was bowing against the wheel, so I indented/cupped the outer rim to allow the spring to nest slightly in the wheel lip. Probably not needed since it is rare that I would be holding the throttle at WOT.

I'd have to say this entire current issue (sticking just off closed throttle) is my doing - in cutting the shaft spring to add the Cruise wheel I have clearly reduced the pretension of the main spring to the point where this has become an issue.

extended. Drove it around a while, and all seemed to be resolved.....

......however, I took the car out again when we went for dinner a few miles from home, it started hanging again. I repositioned the bracket upward & outward (closer to TB) to shift the operating angle of the spring and get more pretension. Once it seems right, I'll weld bridges to the bracket to prevent flex that will cause loss of pretension. I can't make it more vertical or the spring will wrap the wheel circumference in operation. I might need to move the attachment slightly more CCW on the wheel, that would give more leverage for return, since I really can't move the upper attachment much at this point.

I'd have to say this entire current issue (sticking just off closed throttle) is my doing - in cutting the shaft spring to add the Cruise wheel I have clearly reduced the pretension of the main spring to the point where this has become an issue.

extended. Drove it around a while, and all seemed to be resolved.....

......however, I took the car out again when we went for dinner a few miles from home, it started hanging again. I repositioned the bracket upward & outward (closer to TB) to shift the operating angle of the spring and get more pretension. Once it seems right, I'll weld bridges to the bracket to prevent flex that will cause loss of pretension. I can't make it more vertical or the spring will wrap the wheel circumference in operation. I might need to move the attachment slightly more CCW on the wheel, that would give more leverage for return, since I really can't move the upper attachment much at this point.

Last edited:

lookforjoe

True Classic

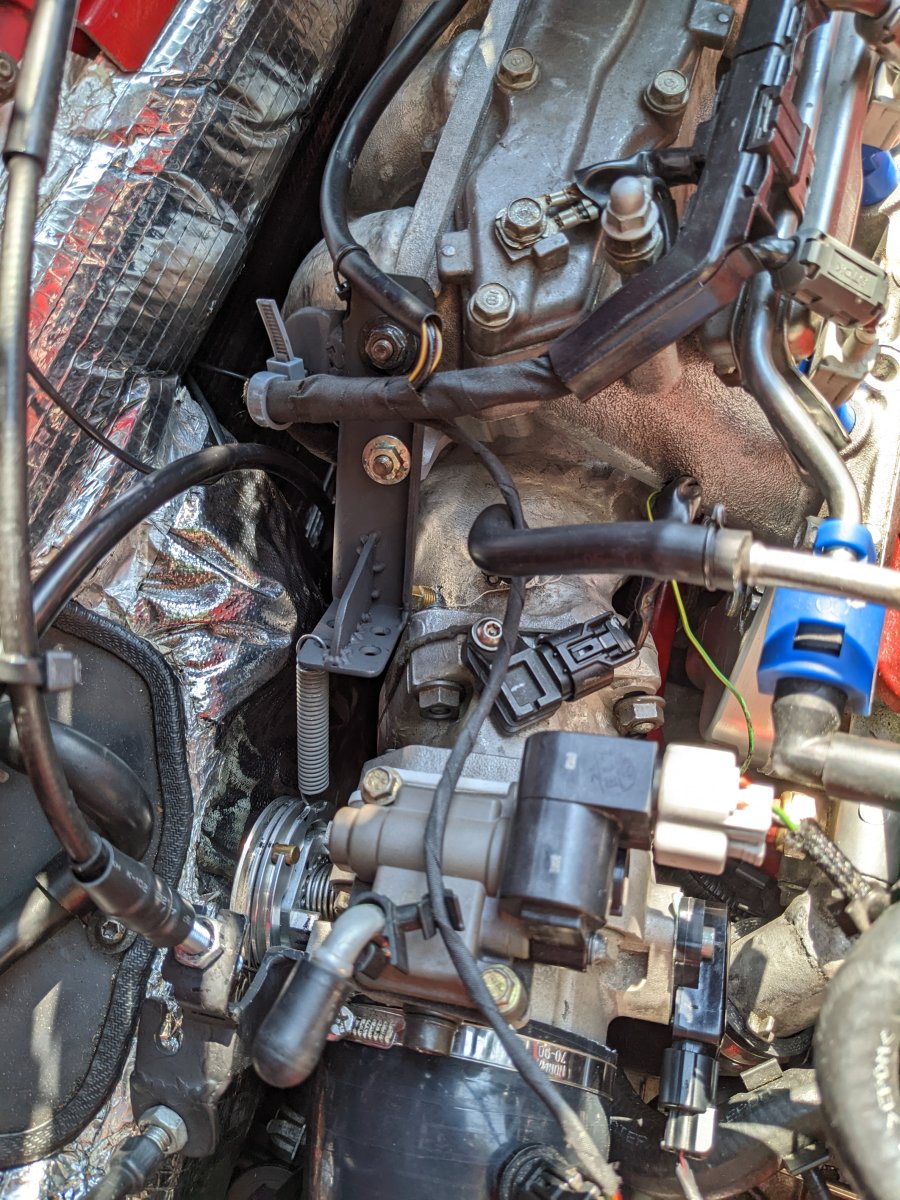

OK - I'm cautiously optimistic at this point. Remade the bracket in a simpler cleaner form. I folded the edges for rigidity, and added a web to prevent the end flexing. I made it with provision for altering the tension and the harness support I lost by removing the factory bracket from that location.

I did find that the TPS adjustment will definitely hang the throttle also, so I had to play with that a while to get a good balance between it registering accurate throttle opening %, and not inhibiting proper return.

I also had the Mrs operate the throttle from the driver's seat so I could see the full range, and the idle/off idle situation. One thing I observed that I hadn't thought about, is that the butterfly does not open more than about 75%. Cutting the lever on the pedal reduces travel to that extent. I never thought about it at the time. Since I have a 70mm TB, it seems that isn't an issue, except that the EMS may not ever be going into WOT values, if that % of opening is insufficient to initiate it. I'll have to look into that aspect.

I did find that the TPS adjustment will definitely hang the throttle also, so I had to play with that a while to get a good balance between it registering accurate throttle opening %, and not inhibiting proper return.

I also had the Mrs operate the throttle from the driver's seat so I could see the full range, and the idle/off idle situation. One thing I observed that I hadn't thought about, is that the butterfly does not open more than about 75%. Cutting the lever on the pedal reduces travel to that extent. I never thought about it at the time. Since I have a 70mm TB, it seems that isn't an issue, except that the EMS may not ever be going into WOT values, if that % of opening is insufficient to initiate it. I'll have to look into that aspect.

Last edited:

lookforjoe

True Classic

Took the X1/9 to a local car show last Thursday, small gathering, maybe 30 cars. There were a few European examples, and a 60's Fiat 500 with full Abarth treatment. That guy imports 500's from Italy built to customer spec. Very cool. He has a few coming in a container in the next two weeks, so he said he would call me so I could check them out.

Several people talked about the show I went to today, also local to me, but much larger. I was warned it is predominately vintage Corvette/ Mustang type crowd. There was a nice range of stock vintage muscle, and many of the newer reboot Camaro/Charger/Mustang things, that have zero interest to me. Several 30's Ford- based hot rods, and an assortment of original spec 50's-60's classics. One MGB and 2 VW bugs. I had a few good conversations, however overall it's just not my cup of tea as it were.

Several people talked about the show I went to today, also local to me, but much larger. I was warned it is predominately vintage Corvette/ Mustang type crowd. There was a nice range of stock vintage muscle, and many of the newer reboot Camaro/Charger/Mustang things, that have zero interest to me. Several 30's Ford- based hot rods, and an assortment of original spec 50's-60's classics. One MGB and 2 VW bugs. I had a few good conversations, however overall it's just not my cup of tea as it were.

lookforjoe

True Classic

Thinking about the throttle opening 'issue'. I went back & read MWB's rationale for the lever height reduction. The premise is that the throttle will be twitchy with the ratio of the stock pedal/lever throw. They recommend 2" reduction, I think I went around 1.75", according to my notes. I never tried it with the stock lever so I don't know just how twitchy it would be, however the response as it is now feels pretty 'normal'.

EDIT: also found I had thought about this aspect back in Mar 2020

I added an additional return spring

can't tell really what angle I have from the cable to the lever barrel, I think I set it basically level

Anyway, since I have the spare pedal, I think I'll cut the second one just an inch & try it. Alternatively, I could remove the modded one, and heat & bend the pedal arm so it doesn't hit the carpet until later in the travel. That would bring the gas pedal rearward though. Since the gas pedal sits well below the brake & clutch pedal height, that may not be such a big deal.

EDIT: also found I had thought about this aspect back in Mar 2020

I added an additional return spring

can't tell really what angle I have from the cable to the lever barrel, I think I set it basically level

Anyway, since I have the spare pedal, I think I'll cut the second one just an inch & try it. Alternatively, I could remove the modded one, and heat & bend the pedal arm so it doesn't hit the carpet until later in the travel. That would bring the gas pedal rearward though. Since the gas pedal sits well below the brake & clutch pedal height, that may not be such a big deal.

Last edited:

kmead

Old enough to know better

Regarding the pedal height, it may be just the way I ‘heel and toe’ but the gas pedal needs to start off from a lower position so when you do press the brake pedal and take up the ’slack’ in the system you have both brake and gas at the same height.Thinking about the throttle opening 'issue'. I went back & read MWB's rationale for the lever height reduction. The premise is that the throttle will be twitchy with the ratio of the stock pedal/lever throw. They recommend 2" reduction, I think I went around 1.75", according to my notes. I never tried it with the stock lever so I don't know just how twitchy it would be, however the response as it is now feels pretty 'normal'.

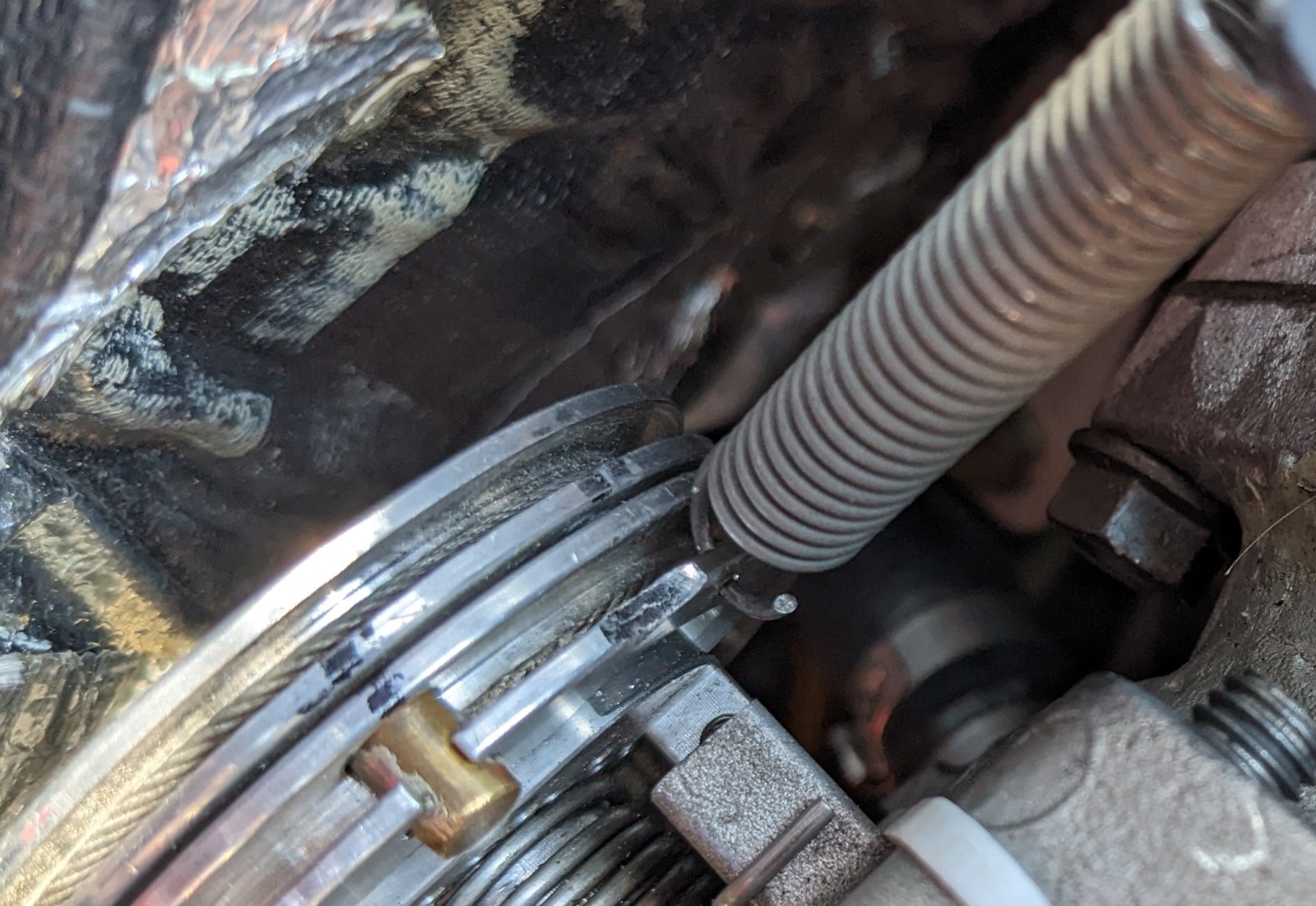

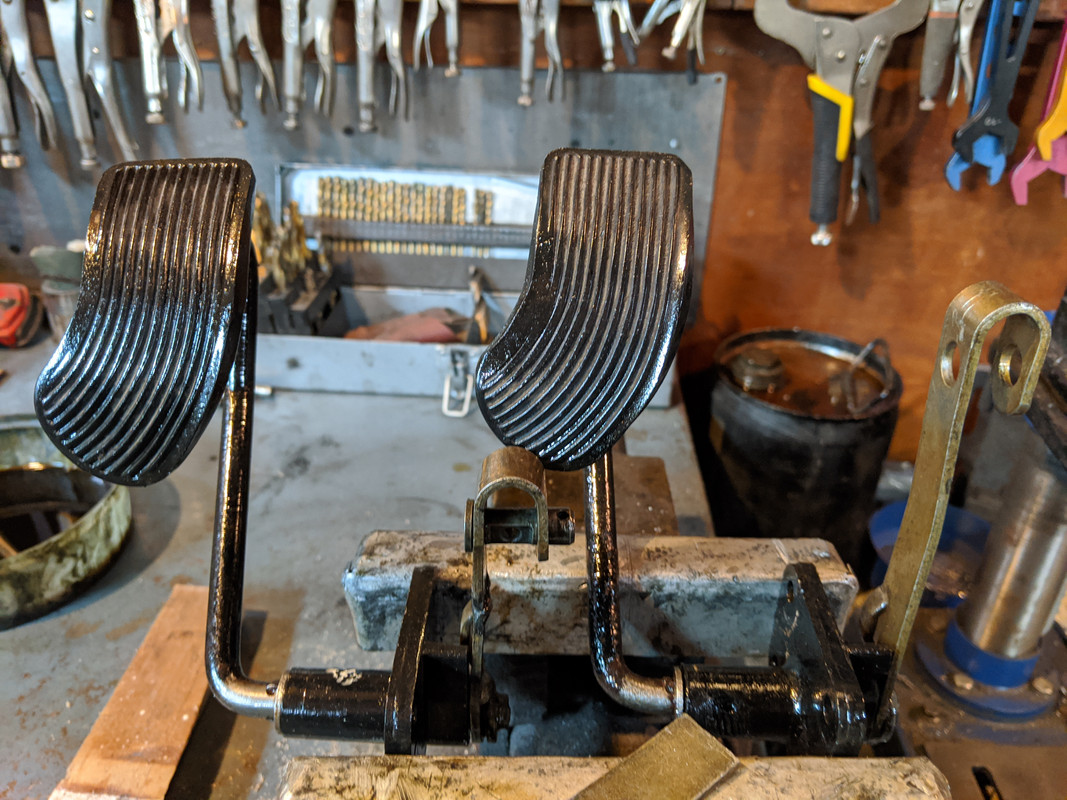

View attachment 66006

I added an additional return spring

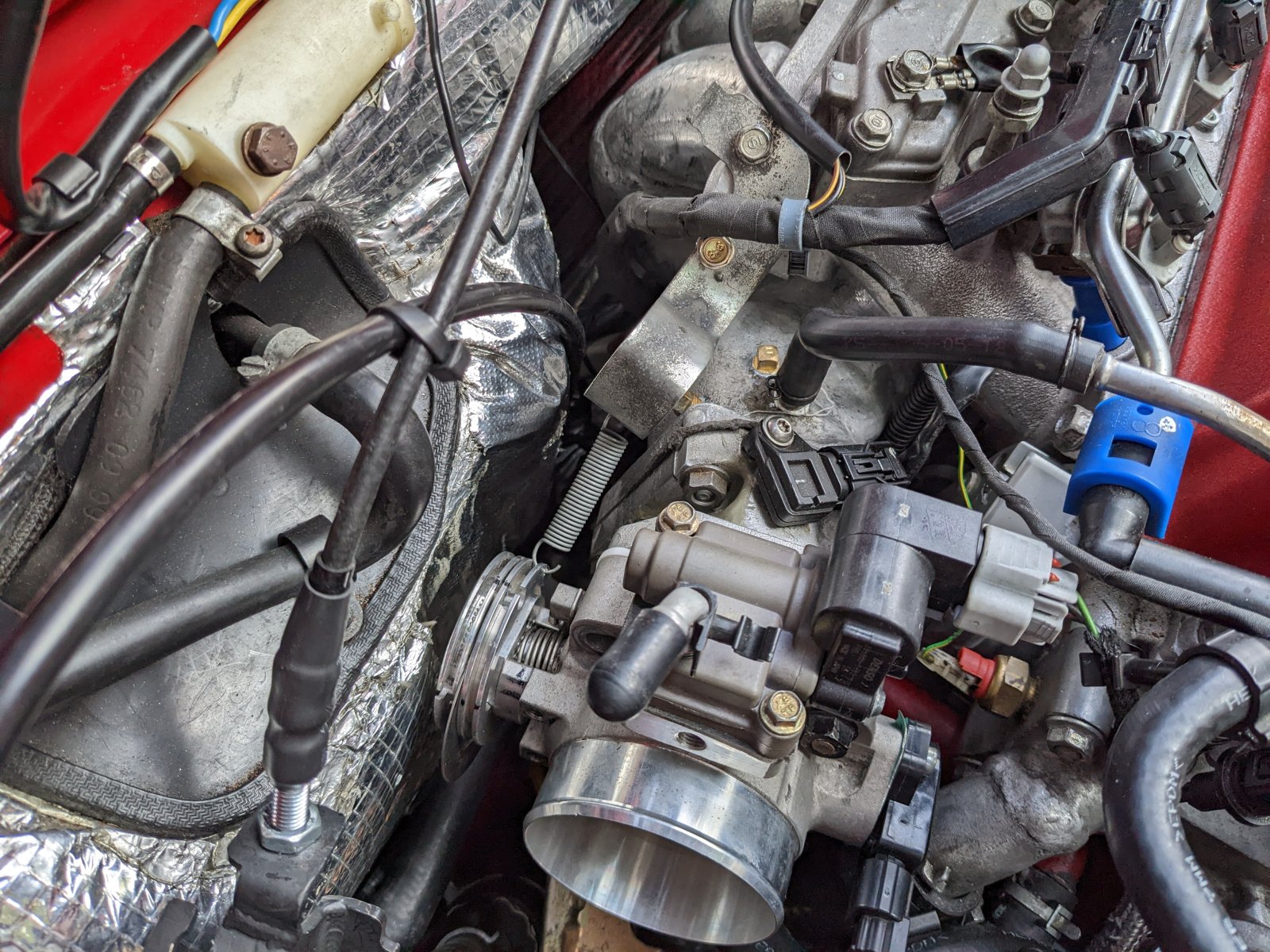

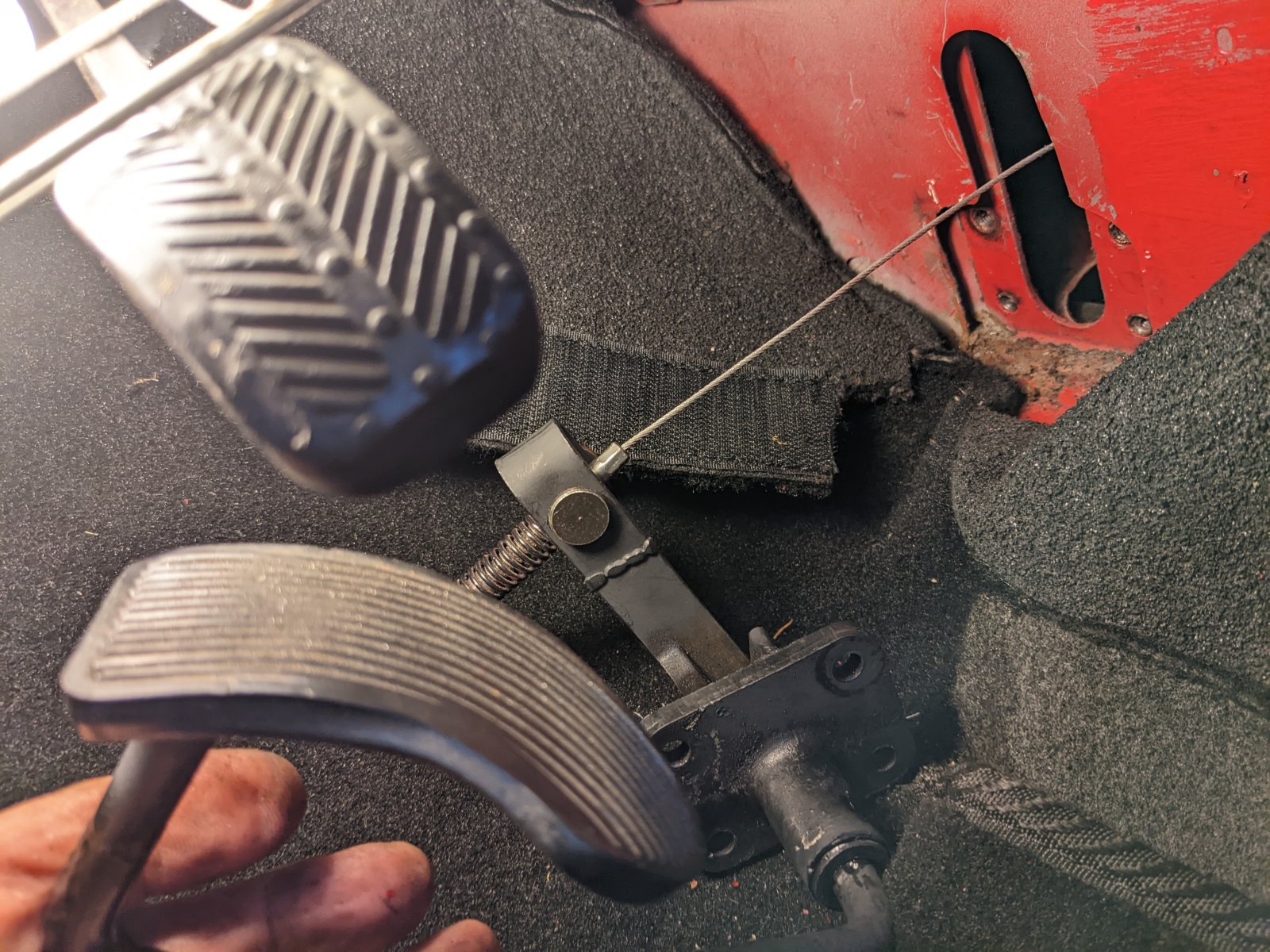

View attachment 66007

can't tell really what angle I have from the cable to the lever barrel, I think I set it basically level

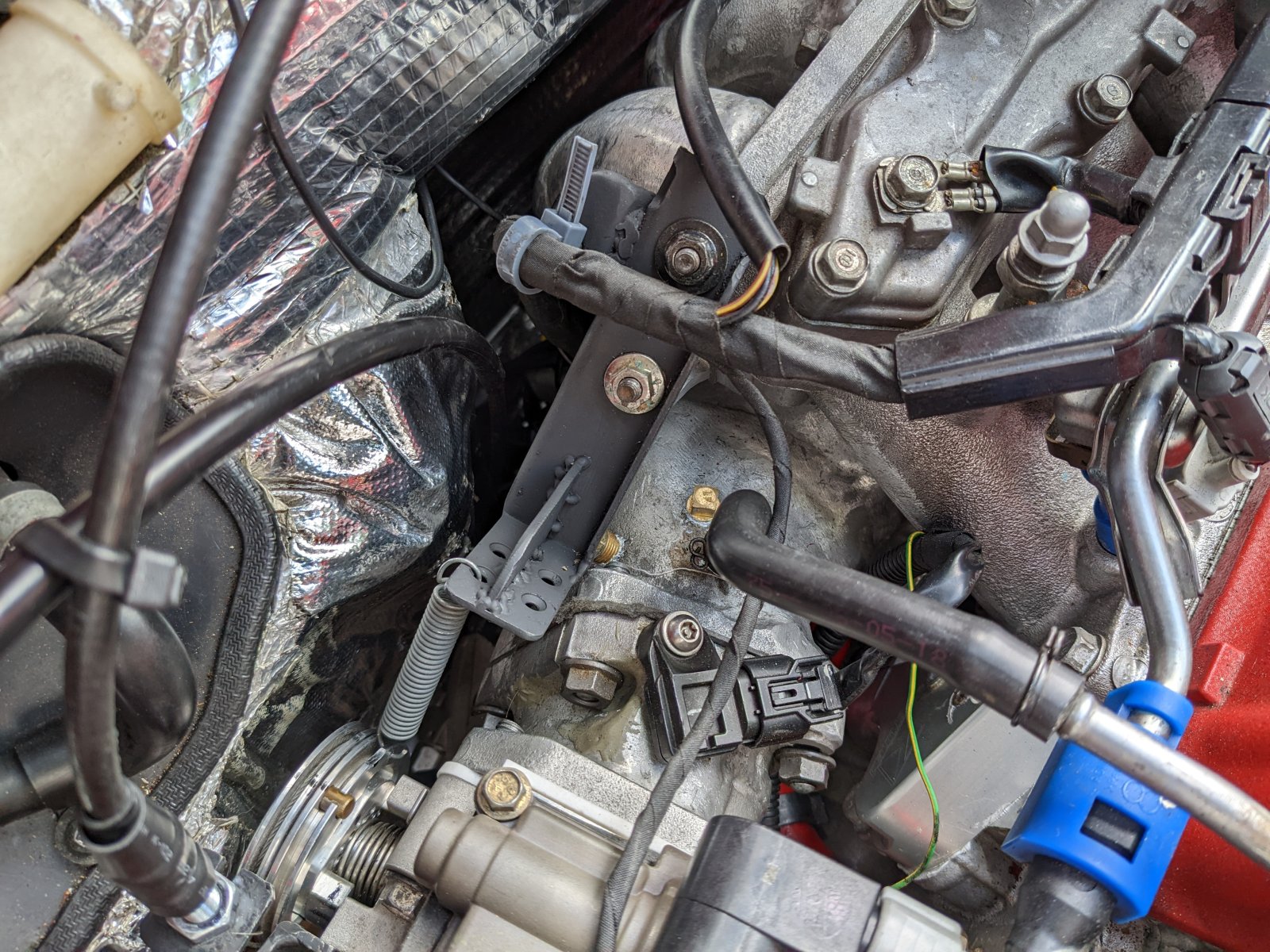

View attachment 66008

Anyway, since I have the spare pedal, I think I'll cut the second one just an inch & try it. Alternatively, I could remove the modded one, and heat & bend the pedal arm so it doesn't hit the carpet until later in the travel. That would bring the gas pedal rearward though. Since the gas pedal sits well below the brake & clutch pedal height, that may not be such a big deal.

View attachment 66009

lookforjoe

True Classic

Regarding the pedal height, it may be just the way I ‘heel and toe’ but the gas pedal needs to start off from a lower position so when you do press the brake pedal and take up the ’slack’ in the system you have both brake and gas at the same height.

Yeah - I was thinking about that on the drive to work - the gas pedal really cannot be any higher/closer to the driver than it is, even though on mine, the brake pedal sits higher than stock with the dual-master setup I have.

lookforjoe

True Classic

Longitudinal

True Classic

Be watchful regarding that added return spring on the pedal. It seems to me that the TB should be the part pulling the pedal back to home position. With a strong return on the pedal, a situation might develop in which the pedal creates enough slack in the cable for the cable to derail at the TB. It's a long length of cable, so the added friction gives more opportunity for a mishap. I have had it happen on much shorter cables.

Last edited:

lookforjoe

True Classic

Be watchful regarding that added return spring on the pedal. It seems to me that the TB she be the part pulling the pedal back to home position. With a strong return on the pedal, a situation might develop in which the pedal creates enough slack in the cable for the cable to derail at the TB. It's a long length of cable, so the added friction gives more opportunity for a mishap. I have had it happen on much shorter cables.

I needed that with the old TB arrangement - the original K-Tuned TB return spring allowed for very light touch to operate the throttle, it was just uncomfortable. I was just thinking this morning that I can now remove that, the added spring at the TB now creates more than sufficient resistance at rest. There is no way for the cable to derail at the TB in normal operation, the cable is looped around 300 degrees of the wheel. I checked a wide array of scenarios when adding the cruise element, since that could in theory introduce enough slack for derailment of the throttle cable.

lookforjoe

True Classic

Had time to cut & weld the pedal arm after work. First I had removed the extra spring off the pedal, and that felt fine in terms of pedal resistance, it was excessive in conjunction with the two at the TB.

Had time to swap it out before the thunderstorms came through, so no time to road test

shorter one coming out

mid length going in after cable transfer. Just noticed there is a small pile of kaka at the base of the opening, I guess I missed cleaning that up when I did the floor pan last winter

Had time to swap it out before the thunderstorms came through, so no time to road test

shorter one coming out

mid length going in after cable transfer. Just noticed there is a small pile of kaka at the base of the opening, I guess I missed cleaning that up when I did the floor pan last winter

lookforjoe

True Classic

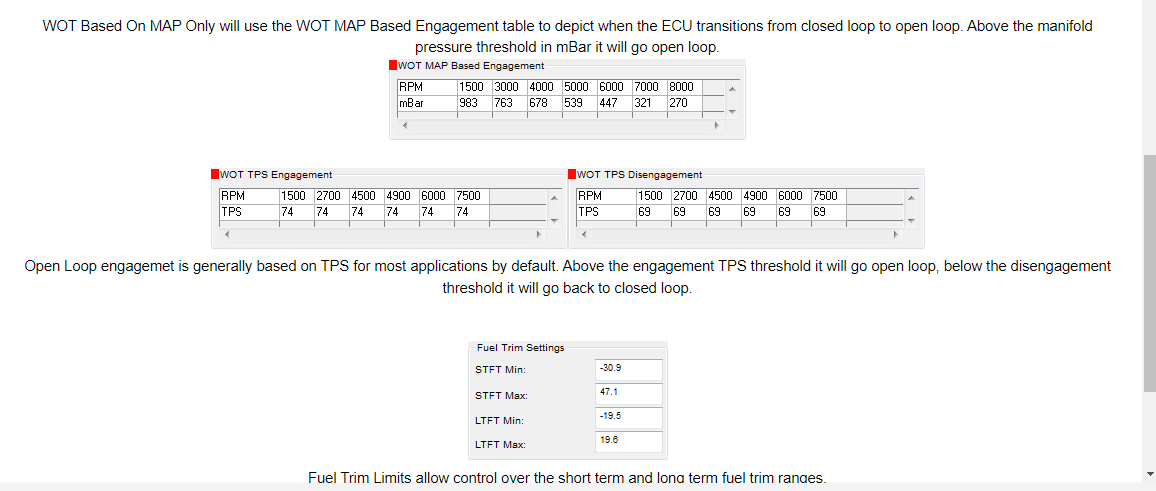

So, car feels good now - normal in other words. Idles well, fuel cut now operates on deceleration as it should. Throttle now operates up to 65% in software - max is 75-80%. With the shorter pedal lever I couldn't get beyond 52% (in software).

EDIT - finally located the settings - after inquiring on the help forum

EDIT - finally located the settings - after inquiring on the help forum

Last edited:

tvmaster

True Classic

Just reading about K20 engines on wikipedia. Is there one, single version most people use in X1/9’s, or are any and all of them used with no rhyme or reason? Which version did you go with?Yeah - I was thinking about that on the drive to work - the gas pedal really cannot be any higher/closer to the driver than it is, even though on mine, the brake pedal sits higher than stock with the dual-master setup I have.

Thanks.

lookforjoe

True Classic

Just reading about K20 engines on wikipedia. Is there one, single version most people use in X1/9’s, or are any and all of them used with no rhyme or reason? Which version did you go with?

Thanks.

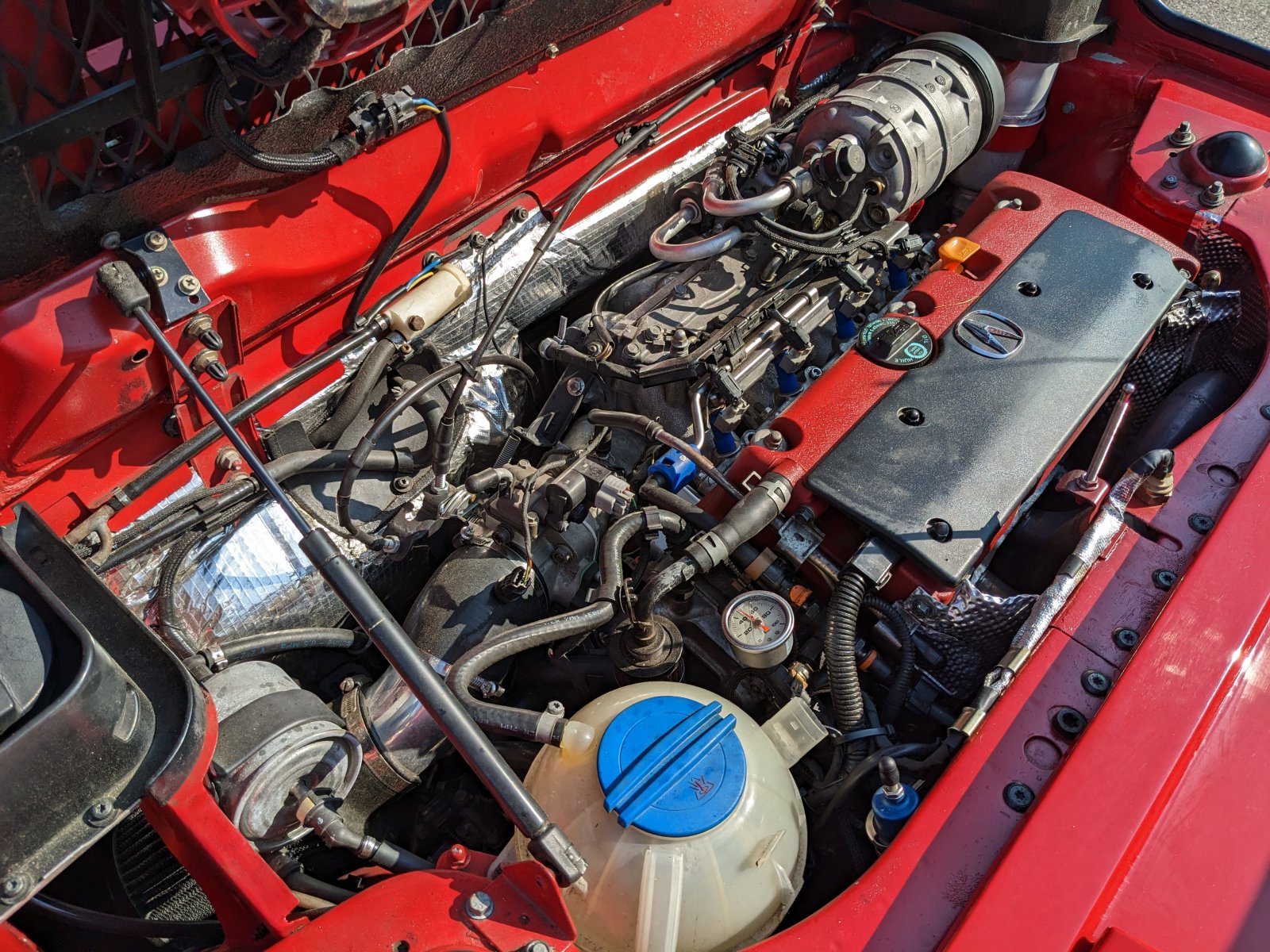

I don't know about K20's - I used a JDM K24A3 (similar to USM K24A2 in spec) General range is 2004-2008, K20 is from the RSX. K24 was also used in bread & butter Hondas, many without iVTEC on intake & exhaust, that's where it can get tricky.

lookforjoe

True Classic

Took some pics & a walk around up at Bear Mountain State Park yesterday, while I was setting up for the Art Academy dinner

Last edited:

Tom Ginefra

True Classic

This is going to kill, when it goes on BAT! I've been in the car, so I know how quick it is. But I still can't wait to see the driving videos.